5-24 LeeBoy 8515E Conveyor Paver

Maintenance

Leeboy uses a leak-detection dye that

may turn the hydraulic oil a slight yellow tint.

Change Hydraulic Oil and FilterChange Hydraulic Oil and Filter

Changing the hydraulic oil removes the accumulation

of dirt, water and mechanical wear particles from the

hydraulic oil system. Clean, ltered oil is critical to

optimize hydraulic system operation. The hydraulic oil

system holds approximately 41 gallons.

Contaminated hydraulic oil can

shorten the expected service life of components in

the hydraulic system.

DO NOT drain the hydraulic oil when it

is hot. Hot hydraulic oil can cause serious personal

injury.

Protect your eyes by wearing

safety glasses when working on hydraulic system

components.

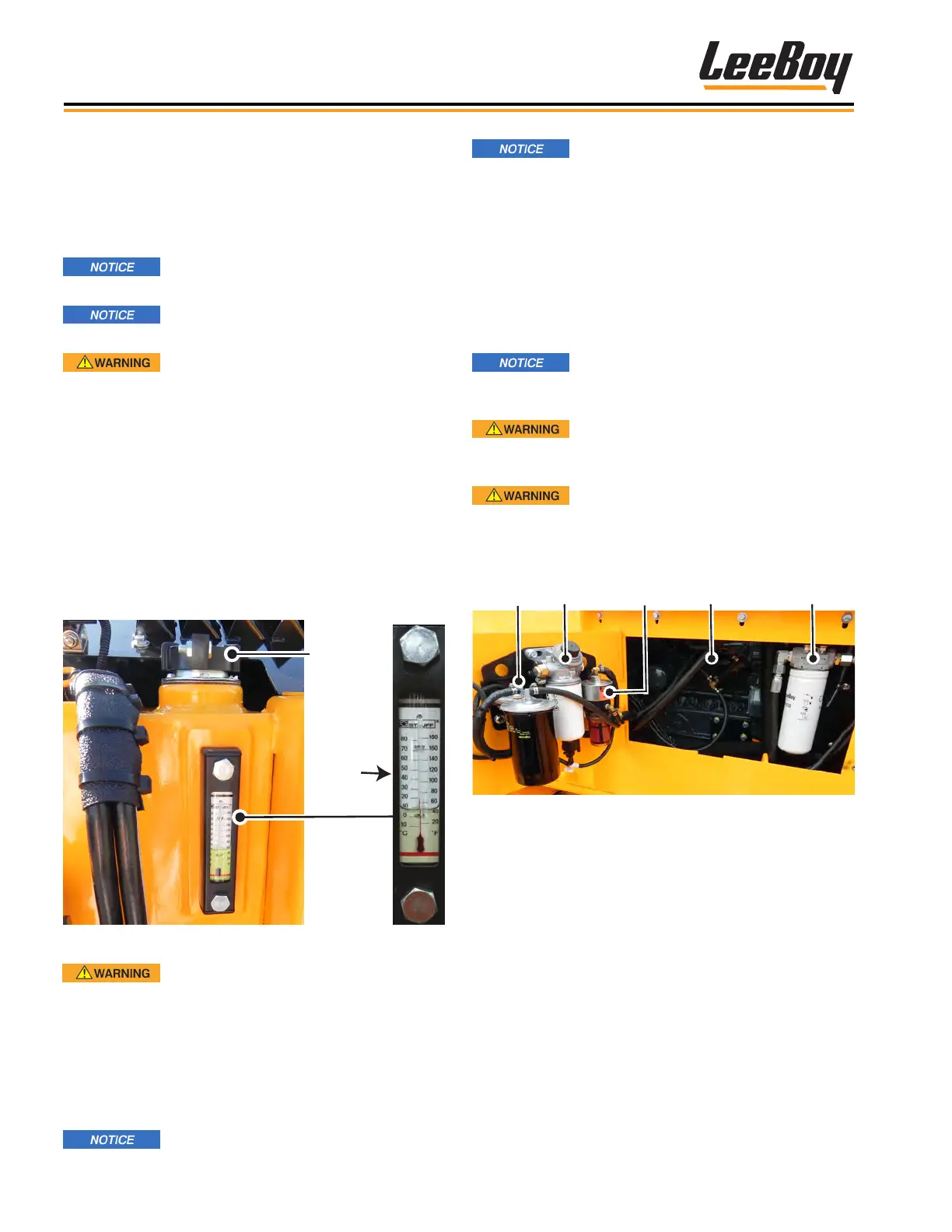

Fuel

Filter

Engine

Hydraulic

Charge Filter

Water

Separator

Fuel

Pump

Figure 5-25. Hydraulic Charge Filter

Use the following procedures to change the hydraulic oil

and charge lter:

1. Stop the engine.

2. Allow the hydraulic oil to cool until it is at a warm

temperature.

3. Slowly remove the hydraulic oil strainer ll cap. Do

not remove the strainer portion under the cap.

4. Place a clean, lint-free cloth over the reservoir ll

tube opening and secure in place with tape.

5. Place a container sufcient to hold the hydraulic oil

as it drains from the drain hose by the access panel

on the right side of machine (close enough for the

drain hose to reach).

HYDRAULIC SYSTEM

Check Hydraulic OilCheck Hydraulic Oil

The hydraulic motors and hydraulic cylinders use the

same hydraulic oil reservoir and hydraulic oil supply.

Take care when working with the

hydraulic system to ensure it is completely clean.

Never allow the hydraulic oil level to

fall too low. Pump damage will occur.

DO NOT use your hands on any

hydraulic hoses, ttings or system component when

checking for leaks. Serious personal injury can

result from an oil leak under high pressure. Oil can

be injected under the skin by high pressure. Protect

the eyes by wearing safety glasses.

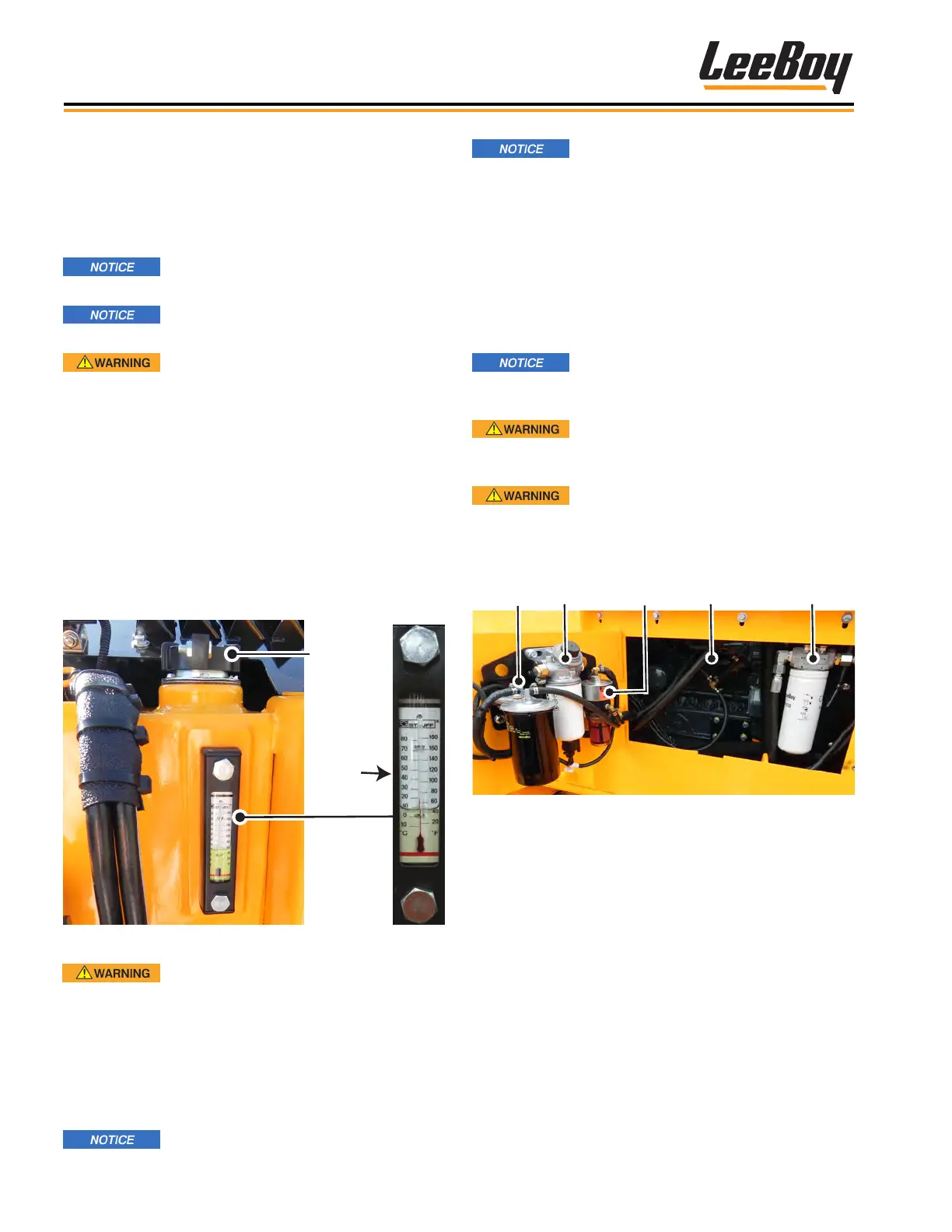

Check the hydraulic reservoir oil level daily using the

sight gauge on the left side of the paver. (Figure 5-24)

Check the hydraulic oil level when the hydraulic oil is at

normal operating temperature for an accurate reading.

If the hydraulic oil level falls below the bottom line (red or

black in color), add more hydraulic oil.

Fill Cap

Sight

Gauge

Fill

Line

Figure 5-24. Hydraulic Oil Cap and Sight Gauge

DO NOT loosen or remove the

hydraulic oil strainer ll cap when the hydraulic oil

is hot. Always loosen the cap slowly to relieve any

pressure in the hydraulic oil reservoir.

• DO NOT use unltered hydraulic oil.

• Check the hydraulic oil level using the sight gauge.

• Keep the hydraulic oil lled to the correct level.

DO NOT overll the hydraulic oil tank.

Loading...

Loading...