5-12 LeeBoy 8515E Conveyor Paver

Maintenance

• Idler bearing housing brackets are not parallel to each

other and the conveyor bed:

• Check the idler bracket. If it appears twisted or

misaligned, slide shaft 1-1/2 inches through the

bearing inside diameter. If the centers are too

far off (more than 1/4 inch), this is why the chain

is climbing the sprocket.

• If excessive, replace chain or sprocket.

You will need a ratchet, extension and 15/16 socket to

make the adjustment. DO NOT use an impact wrench!

Use the following procedure to adjust the ight chains:

1. Use the ratchet to remove the four wing bolts on

each side, then fold out both hopper wings. (Steps

2-3 on Page 5-5)

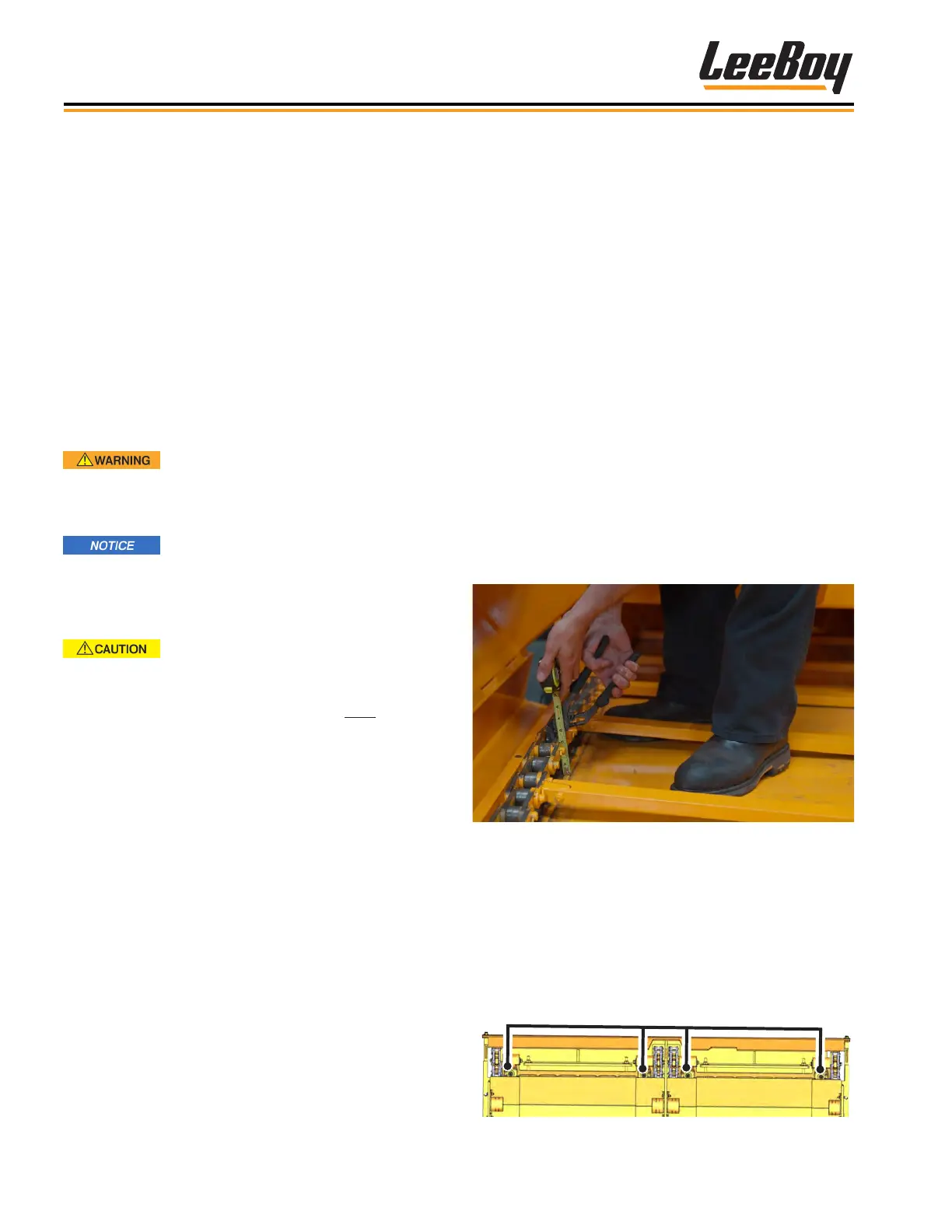

2. Use a pair of pliers and minimal force to pick up

the chain near the center of the conveyor bed on

each side, then measure and compare the slack

observed. (Figure 5-6)

Figure 5-6. Compare Slack Observed

3. Start the engine to raise the conveyor bed, then

insert safety prop. (Steps 2-3 on Page 5-5) Turn

off engine.

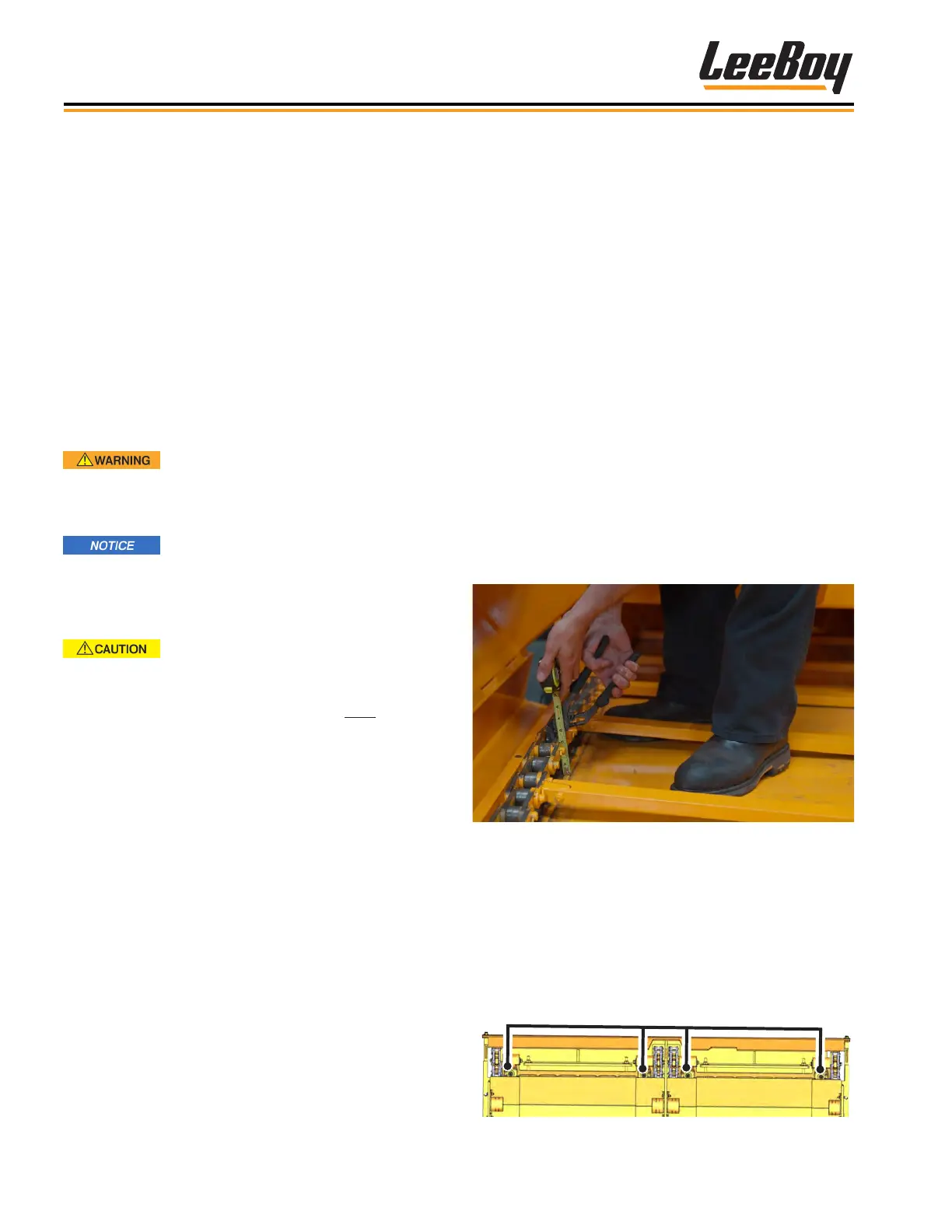

4. Loosen the two idler mount bolts on the left or right

conveyor (or both if adjusting both conveyors),

using an allen wrench to hold the bolt on top while

loosening the 4 nuts underneath. (Figure 5-7)

Figure 5-7. Idler Mount Bolts

MAINTENANCE ADJUSTMENTS

Certain components of the paver need adjustments

for optimum performance, operation and general

maintenance.

Conveyor Flight ChainsConveyor Flight Chains

The conveyor ight chains must be adjusted every 100

hours. If irregular movement of the conveyor occurs, an

adjustment is needed regardless of the time interval.

NOTE: If the adjustment bolt has reached its

maximum adjustment level, remove two links in

the conveyor chain and add a half link. This repair

should bring the adjustment bolts back to full travel.

Entanglement hazard! DO NOT run

the engine while checking and servicing conveyor

components. NEVER perform any adjustments while

the engine is running.

In cold weather, keep conveyor

ight chains properly oiled with cleaning solvent

or release agent. This will prevent conveyor bars

from sticking. Neglect could result in conveyor bar

damage or drive chain failure.

DO NOT adjust the conveyor ight

chains too tight! Clearance (slack) is required for

material to pass under and between chain rollers and

the front idler sprocket. There must be mild tension-

-just enough to take up slack and prevent the chains

from “knuckling.”

The feeder-breaker chain operates most efciently with

a slight amount of slack on the return side. The chains

should not:

• Be pulled too tight.

• Hang too loose.

• ALWAYS adjust both chains exactly the same.

The chains should be slightly slack with constant

tension, measuring slack of 1-1-1/2 inch from the

conveyor bed. A chain(s) “popping and cracking”

indicates the chain is climbing the sprocket, which can

be caused by:

• Excessive run-out of the front sprockets:

• Check to verify sprocket run-out pin on the

shaft. Run-out should not exceed .030 inches.

• If excessive, replace chain or sprocket.

Loading...

Loading...