Maintenance

LeeBoy 8608 Commercial Paver5-12

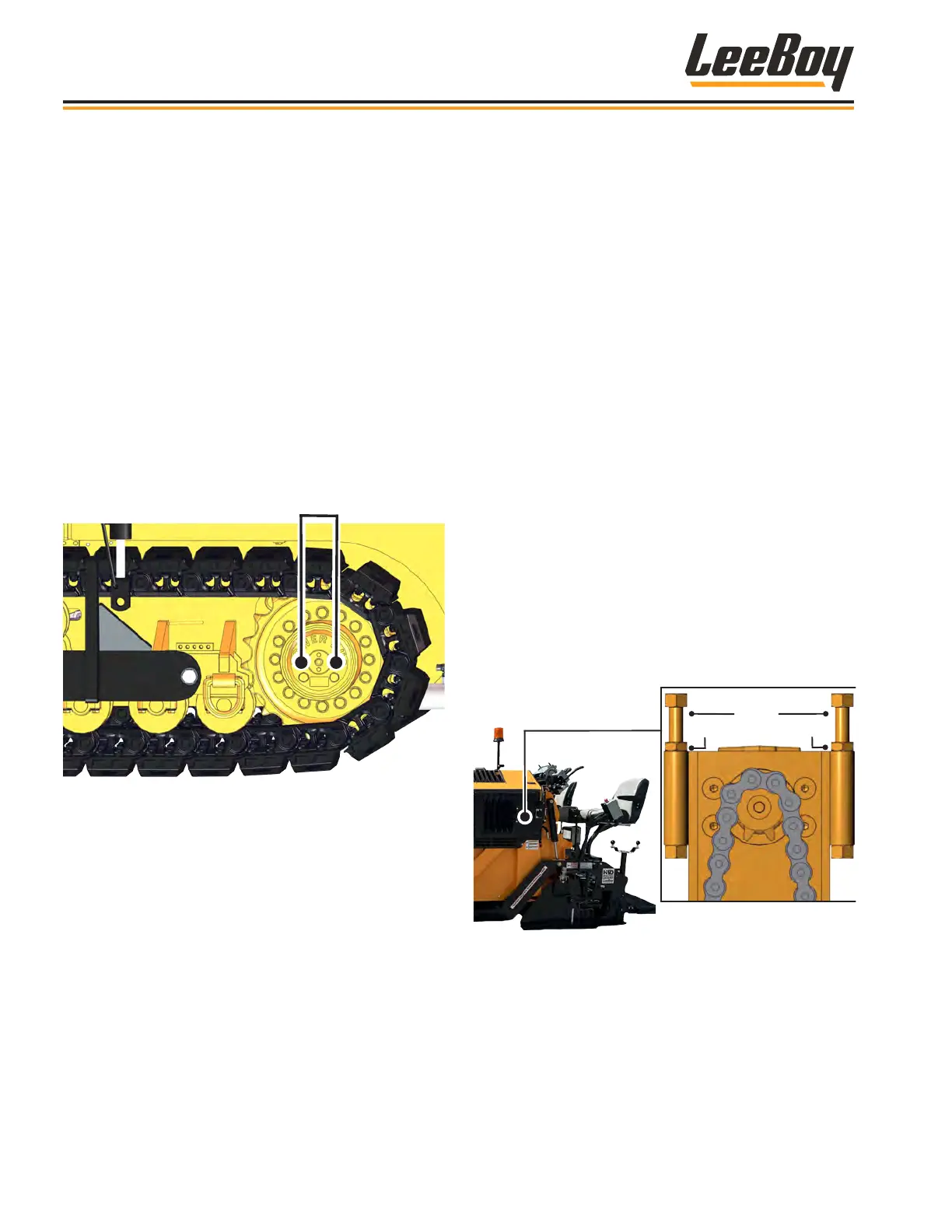

Torque Hub LubricationTorque Hub Lubrication

Check the torque hub oil level at the rear of the tracks

weekly to ensure optimum operation. To check the

torque hub oil level:

1. Move paver so that one of the torque hub plugs is in

the 12 o’clock position and the other is in the 3 or 9

o’clock position as shown in Figure 5-4.

2. Remove the plug in the 3 (or 9) o’clock position.

3. If oil comes out, no oil is needed. Reinsert the plug

and tighten.

4. If oil does not come out, remove the top plug and ll

with SAE 90 WT gear oil until oil starts to appear at

the plug.

5. Replace plug and repeat process on the other

torque hub.

Figure 5-4. Torque Hub Plugs

MAINTENANCE ADJUSTMENTS

Certain components of the paver need adjustments

for optimum performance, operation and general

maintenance. Keep chains clean, lubricated and

properly adjusted.

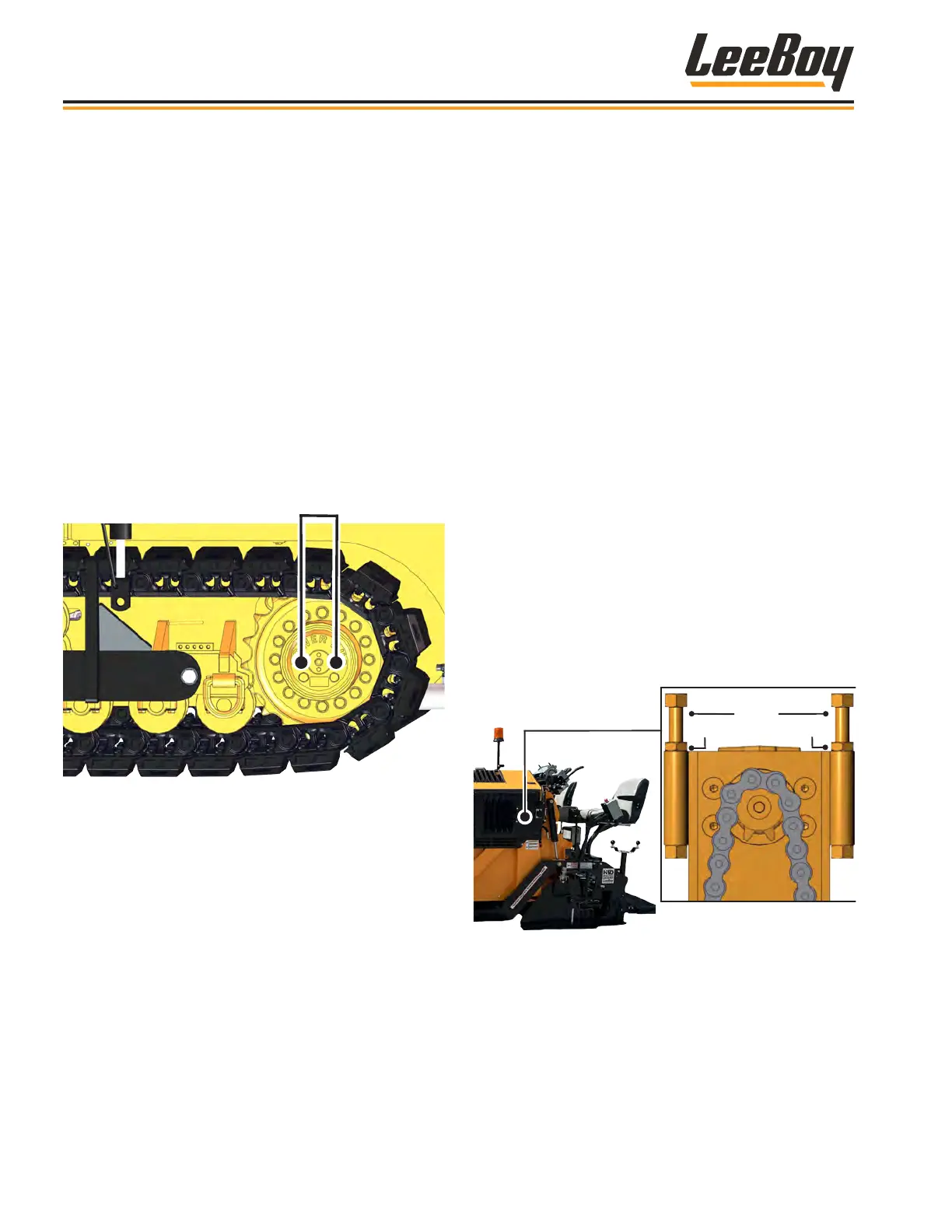

Conveyor Drive ChainsConveyor Drive Chains

Maintaining proper conveyor drive chain alignment is

essential for conveyor performance and maximizing

chain and sprocket life. You can access the conveyor

drive chains via the engine access panels on each side

of the paver.

Keep chains clean, lubricated, and properly adjusted.

Inspect the drive chain tension on each side of the

paver regularly. There should only be 1/4-inch of

slack on each chain. If you notice any slippage on

either conveyor, the drive chain(s) may be loose and

adjustment is necessary. (See Page 5-51 for slack

tension adjustment.)

Use the following procedure to adjust the conveyor drive

chains:

1. Shut off engine.

2. Loosen the jam nuts on the chain adjuster. (Figure

5-5)

Drive

Chain

Jam Nut

Jam Nut

Adjustment

Bolts

Figure 5-5. Conveyor Drive Chain Bolts

3. Turn the chain adjuster to loosen or tighten the

chain, leaving approximately 1/4-inch of slack. DO

NOT overtighten.

4. Retighten jam nuts.

5. Repeat steps on the opposite drive chain.

Loading...

Loading...