Maintenance

LeeBoy 8608 Commercial Paver5-30

Generator Voltage TestingGenerator Voltage Testing

The generator is belt-driven (from the engine). When

the engine is running at 2100 RPMs (paving speed), the

generator produces 240 VAC. (Figure 5-27)

This procedure must be performed by

a qualied electrical technician due to the danger of

electrical shock.

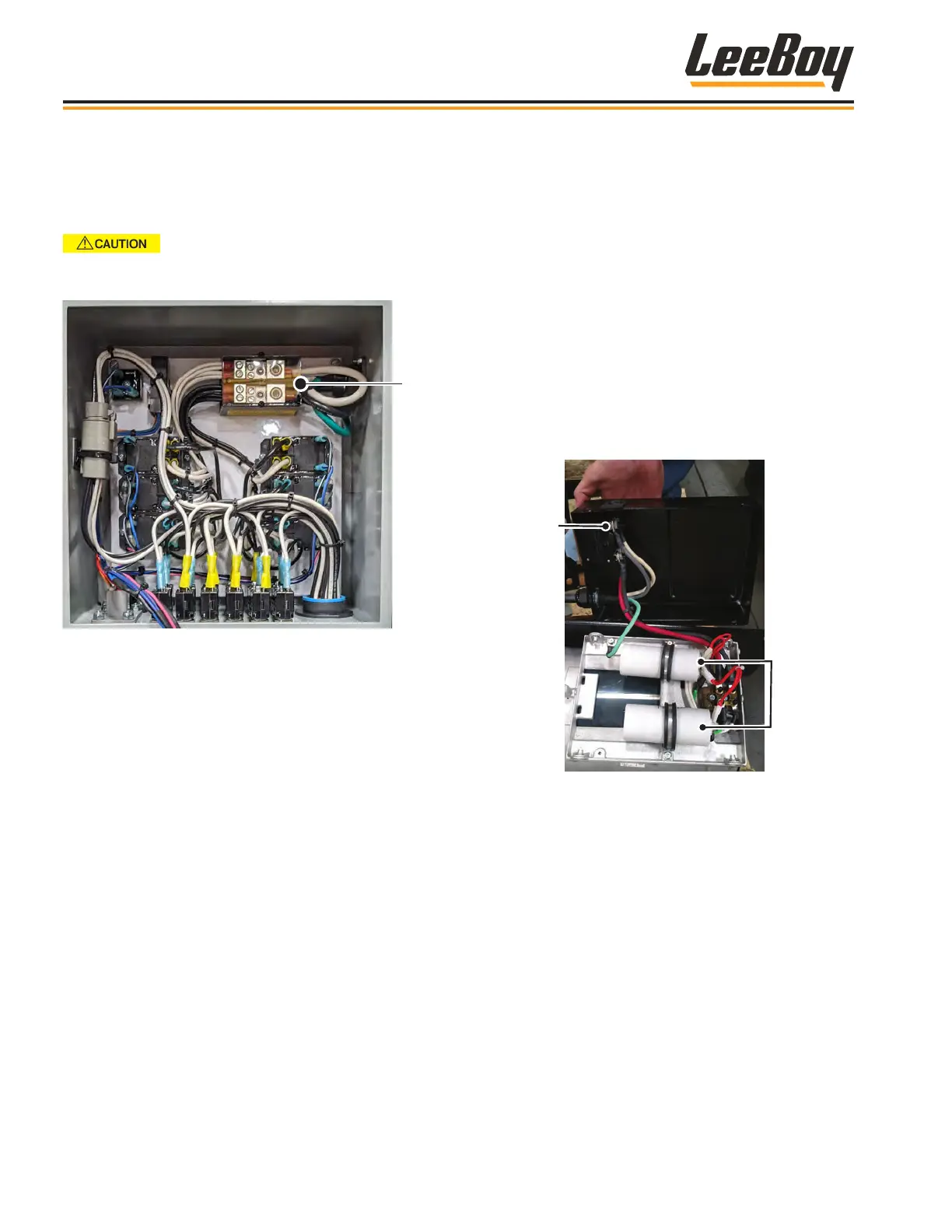

Figure 5-27. Generator Voltage Testing

Test the generator voltage at the generator and at the

electric heat control box:

1. Use a volt meter to measure between the two main

input wires L-1 (black wire) and L-2 (white wire) at

the terminal block, which should measure 240 ± 5

VAC. If you measure from L-1 to the frame of the

paver, or ground, the voltage should be approxi-

mately 120 VAC.

2. If the voltage is lower, make certain the generator is

turning the correct speed by testing with a Hz meter

(valve should be 60 - 63 Hz.

3. If the voltage is still low, contact your authorized

LeeBoy dealer for generator speed tuning (see next

section).

Generator Capacitor Generator Capacitor

ReplacementReplacement

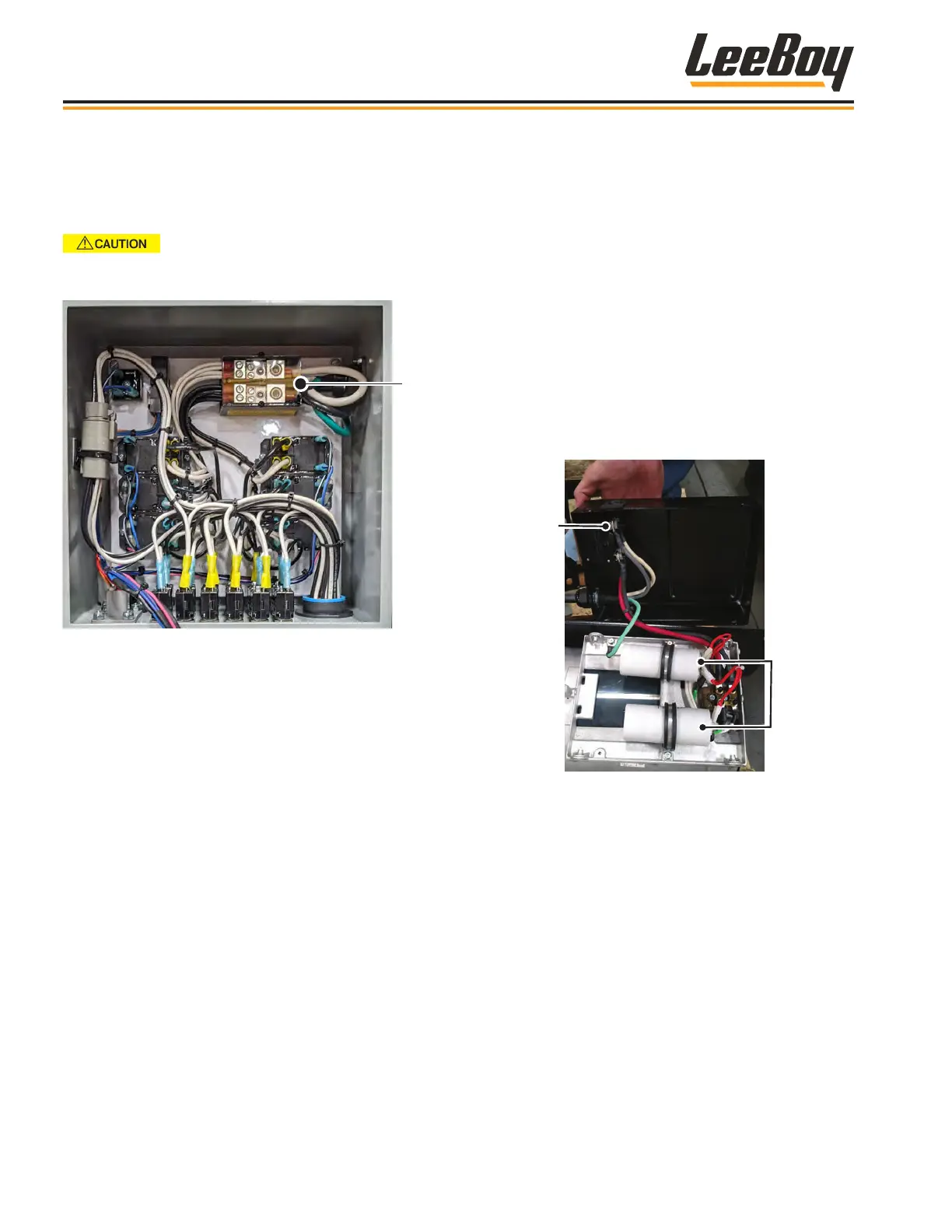

The two generator capacitors control and regulate

voltage while the machine operates. (Figure 5-28) If

the capacitor fails, the voltage will drop below normal or

no output at all. It is located under the generator cover.

If experiencing a drop in voltage, replacing the capacitor

will help determine if the capacitor is at fault.

To perform this procedure:

1. Shut down the machine.

2. Detach the wires on top of the capacitor.

3. Remove the capacitor and replace with new one.

4. Reattach wires.

Main

Input Wires

Capacitors

Figure 5-28. Generator

Loading...

Loading...