55

Maintenance

LeeBoy 8608 Commercial Paver 5-35

Torque HubTorque Hub

If the torque hub has been damaged or worn, use to

following procedures for replacement.

1. Park paver on a level surface.

2. Jack up the paver at least two feet and place on

sturdy jack stands.

3. Place blocks sufcient to support the hydraulic

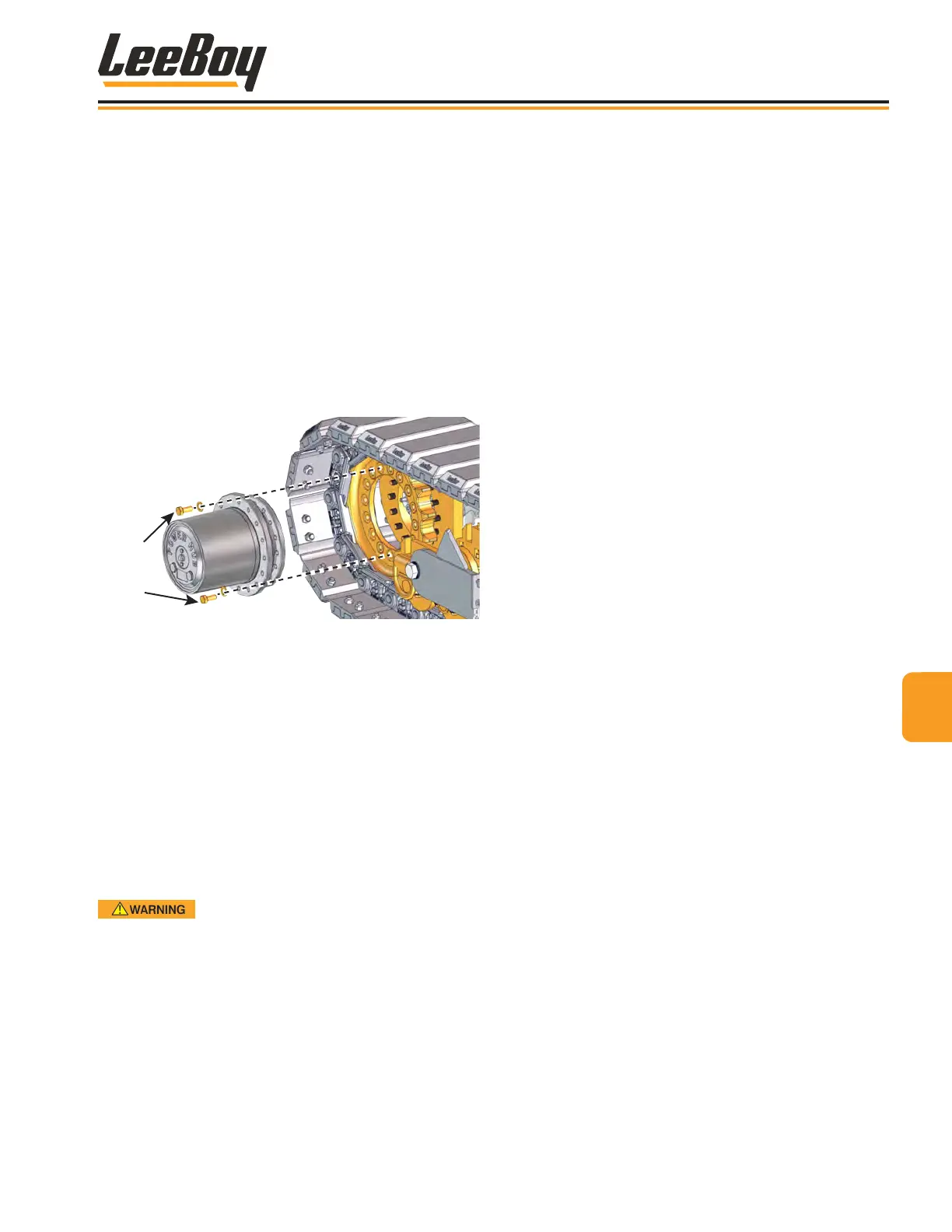

motors underneath them. (Figure 5-37)

NOTE: Mark location of torque hub to the

undercarriage before removing to ensure

the drive motor is reinstalled in the same

position.

5/8-Inch

Bolts

(16)

Figure 5-37. Hydraulic Motor and Torque Hub

4. Remove the 16 5/8-inch bolts and carefully remove

torque hub. Check O-Ring on the hydraulic motor

and replace if worn.

5. Install new torque hub into position to align with the

hydraulic motor. Place thread-locking adhesive on

torque hub bolts and torque bolts. (See Torque

Tables in Section 2).

6. Fill torque hub with oil. (Page 5-14)

7. Lower paver to the ground.

8. Start paver and check for any leaks with engine

running.

Stop the engine immediately if any

hydraulic leak is noted. DO NOT start the engine

until the leak has been repaired.

Replace TracksReplace Tracks

Tracks may need to be replaced due to wear or

damage. You will need an assistant for this procedure:

1. Locate track tension manifold on the hydraulic tank

(left side of the paver) and place a pan underneath

to catch hydraulic oil that will drain during the next

step. (Page 5-49)

2. Unscrew the track tension relief cartridge out of the

aluminum block about three turns until you hear the

tension pressure release.

3. Remove the master pin from the track. (Figure

5-47)

4. Drive out the pin.

5. Put the paver in reverse and back up slowly until

clear of the track. Discard track.

6. Place new track in front of the paver, positioning

the end of track with the three (3) hinges at the front

idler.

7. Drive paver forward onto the new track until it is

aligned at rear of the track drive tires.

8. Using a 4’ x 11/16” rod with a two-inch leg on one

end and a handle on the opposite end, the assistant

should hook rod onto the outer hinge of the track

on the rear side, pulling on rod while the operator

slowly moves paver forward.

9. The assistant can now hook rod at front of the track,

pulling it on at the front of idler as the operator

slowly moves in reverse until the track connects

over top of the front idler..

10. Insert pin and weld keepers at end of pin.

11. Screw track tension manifold relief cartridge back

into place and check hydraulic oil level. Add more if

needed.

Loading...

Loading...