Extendable Push RollerExtendable Push Roller

The extendable, oscillating push roller option offers

even more exibility for maintaining contact with an

asphalt material truck. (Figure 4-84) Extending the

rollers various lengths as needed allows better contact

for material trucks of all sizes, decreasing the load on

the paver so it’s easier to push the truck.

Use the same procedures in the previous section for

operation.

Figure 4-84. Extendable Push Roller

Rubber Track OptionRubber Track Option

The LeeBoy 8608 Commercial Paver is equipped

with poly-pad tracks, but a rubber track option is also

available.

Horizontal Flight ScrewsHorizontal Flight Screws

Some screed operators prefer horizontal ight screws.

(Figure 4-85) This option is not an add-on option--it

must be ordered when purchased.

Figure 4-85. Horizontal Flight Screw

TopconTopcon®® Sonic and Dual Grade Sonic and Dual Grade

ControlControl

Topcon® sonic grade control, dual grade control and

slope options offer paving professionals screed control

for improving smoothness along with assuring accurate

slope and material thickness. Sonic trackers continu-

ously measure the elevation over the surface, automati-

cally averaging and adjusting the tow point cylinder on

the paver. These controllers send signals to the screed

to precisely maintain mat thickness and slope as you

pave. Most states require this technology for state road

paving jobs to ensure smoothness and continuity on

roadways.

Choose from one of three options: Sonic Grade Control

(one side); Dual Grade Control or Dual Grade Control

and Slope. The dual grade controls automatically main-

tain a set depth on both ends of the screed. The Dual

Grade and Slope controls maintain a set depth on one

end of the screed and a set slope on the other end.

The paver must be pre-wired for TopCon technology. If

equipped with this option, be sure to unplug and store

the system after use. Always recap the cables to pro-

tect the connectors when not in use.

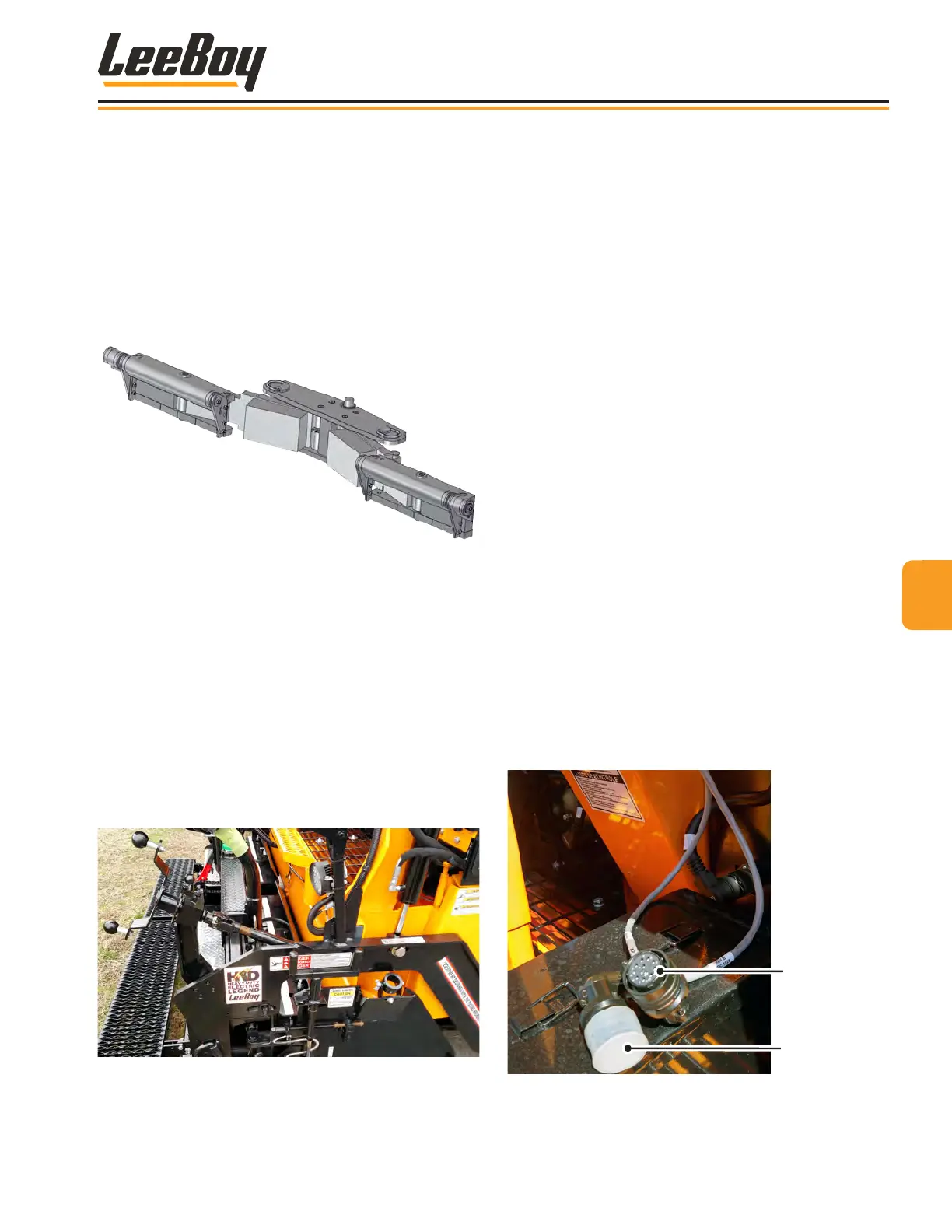

To initiate the TopCon P-32 system:

5. Start the engine and idle a few minutes to warm

hydraulic oil throughout the machine.

6. Connect the P32 plugs into the connectors on the

cables extending from the right side of the main

control panel column. (Figure 4-86) Each plug will

only t into its correct connector.

Connector

(Shown with Cap)

Connector

Figure 4-86. Connector Cables

44

Operation

8608 Commercial Paver 4-41

Loading...

Loading...