55

Maintenance

LeeBoy 8608 Commercial Paver 5-33

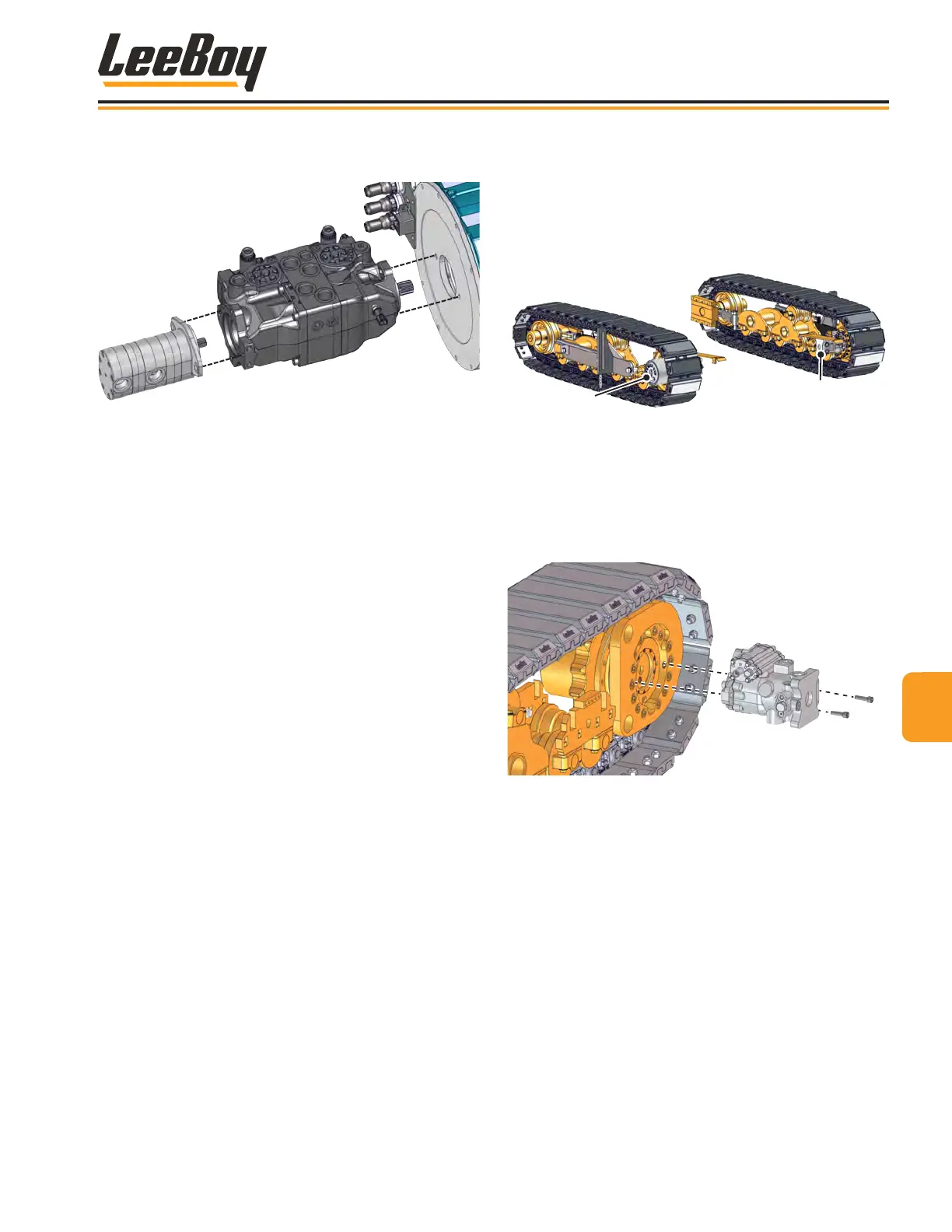

4. Remove the two screws on the pump mount (one on

each side of mount). (Figure 5-33)

Tandem Pump

Bolts (2)

Drive Pump

Bolts (2)

Figure 5-33. Hydraulic Pump Assemblies

5. Using a sling, carefully lift the pump assembly out of

the machine and place on a at surface.

6. Remove and inspect the O-ring(s) on end of the

pump for wear or damage. Replace if needed.

7. Put a small amount of hydraulic oil onto the O-Ring

and reinstall.

8. Align the 2 mounting holes with the mounting on the

pump.

9. Reattach with the two mounting screws and torque

(Refer to Torque Tables in Section 2.)

10. Remove plug caps and reconnect hydraulic hoses

to pump as previously labeled.

11. Check hydraulic oil level. Add more if needed.

12. Start the paver and check to be sure there are no

hydraulic oil leaks.

13. Let machine idle approximately 10 minutes to allow

the pump and motor cases to ll with hydraulic oil.

Two-Speed Hydraulic MotorsTwo-Speed Hydraulic Motors

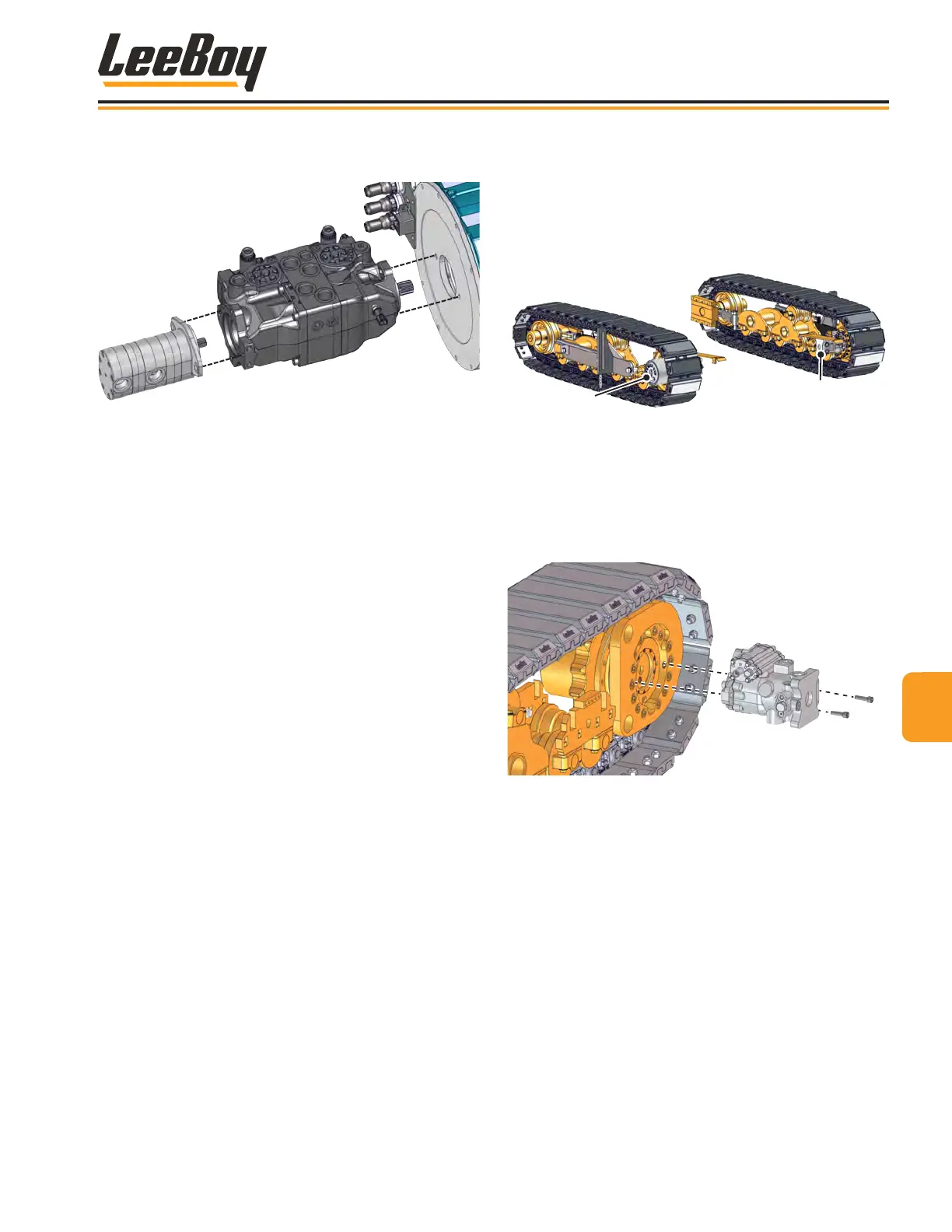

1. Move paver onto a level ramp where you can

access the undercarriage.

2. Disconnect, label and plug ttings on hydraulic

hoses to the hydraulic motors. (Figure 5-34)

Figure 5-34. Torque Hubs and 2-Speed Motors

3. Place blocks sufcient to support the hydraulic

motors underneath them.

4. Remove the two screws and lock washers attaching

the hydraulic motor to the torque hub and carefully

separate motor from the torque hub. (Figure 5-35)

Figure 5-35. Remove 2-Speed Motor

5. Remove the O-Ring and drain hydraulic oil from the

motor. Discard or repair the motor as appropriate.

6. Lubricate a new O-ring with hydraulic oil and install

onto the torque hub.

7. Reattach new or rebuilt hydraulic motor to torque

hub. (Refer to Torque Tables in Section 2 to torque

bolts.) Reconnect hydraulic hoses.

8. Start the engine and let machine run for 10 minutes

to work air out of the system. Check for any leaks.

Loading...

Loading...