Maintenance

LeeBoy 8608 Commercial Paver5-46

Main Screed Wear PlateMain Screed Wear Plate

The screed wear plates can wear out over time and

must be replaced if the plate has worn to less than

1/4-inch thick. Poor maintenance, paver cleaning,

asphalt mixes containing hard aggregate and improper

material ow can contribute to excessive wear on the

main screed and extension wear plates. Correct screed

heating also helps prevent excessive material build-up.

An uneven, worn screed plate will produce an inferior

mat

1. Retract screed extension completely.

2. Unbolt and remove the rear walk boards. (Figure

5-57)

3. Unbolt and remove upper and lower screed covers.

4. Remove bolts on the heating element covers and

remove. Disconnect wiring.

Walkboards

Screed

Covers

Figure 5-57. Walk Boards and Covers

5. Grasp handle and slide out inner screed elements

covers as shown in Figure 5-58 to access wear

plate bolts.

Figure 5-58. Inner Screed Element Covers

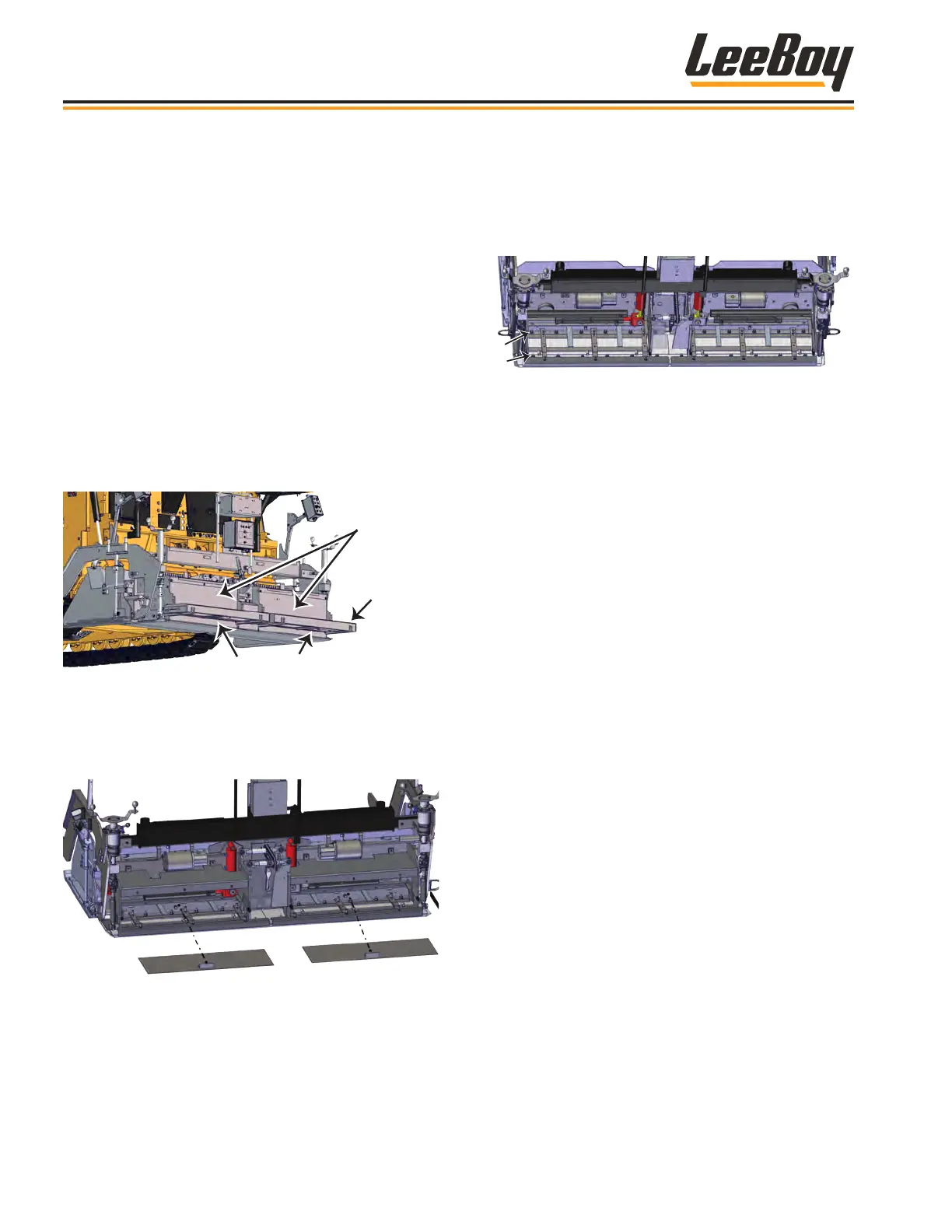

6. Remove both rows of bolts holding the wear plate to

the bottom of the screed. (Figure 5-59)

NOTE: Clamp the center portion of the screed frame

to hold the frame in place before lifting it

from the worn wear plate.

Wear

Plate

Bolts

Figure 5-59. Wear Plate Bolts

7. Raise the screed completely.

8. Slide the worn wear plate from under the screed.

9. Clean all material buildup on the screed frame.

10. Set new wear plate level on three blocks, placing

one block in the center and one at each end.

11. Lower the screed frame down onto the new wear

plate.

12. Install center and side bolts rst (front and rear)

to hold the new wear plate in place, then install

remaining bolts. DO NOT tighten the bolts until all

bolts are installed.

13. Loosen the plate on the slotted side to adjust the

crown. This will move the screed frame in and out

on the wear plate to help align the bolts on the

opposite side.

14. Install the remainder of the front bolts, then install

the rear bolts, ensuring the screed frame and wear

plate are at.

15. Torque bolts (Refer to Torque Tables in Section

2) starting inside, then moving outward, by rotating

from the left to the right side to keep the screed

relaxed.

16. Reinstall the screed covers in reverse order, then

the walk boards.

Loading...

Loading...