Maintenance

LeeBoy 8608 Commercial Paver5-32

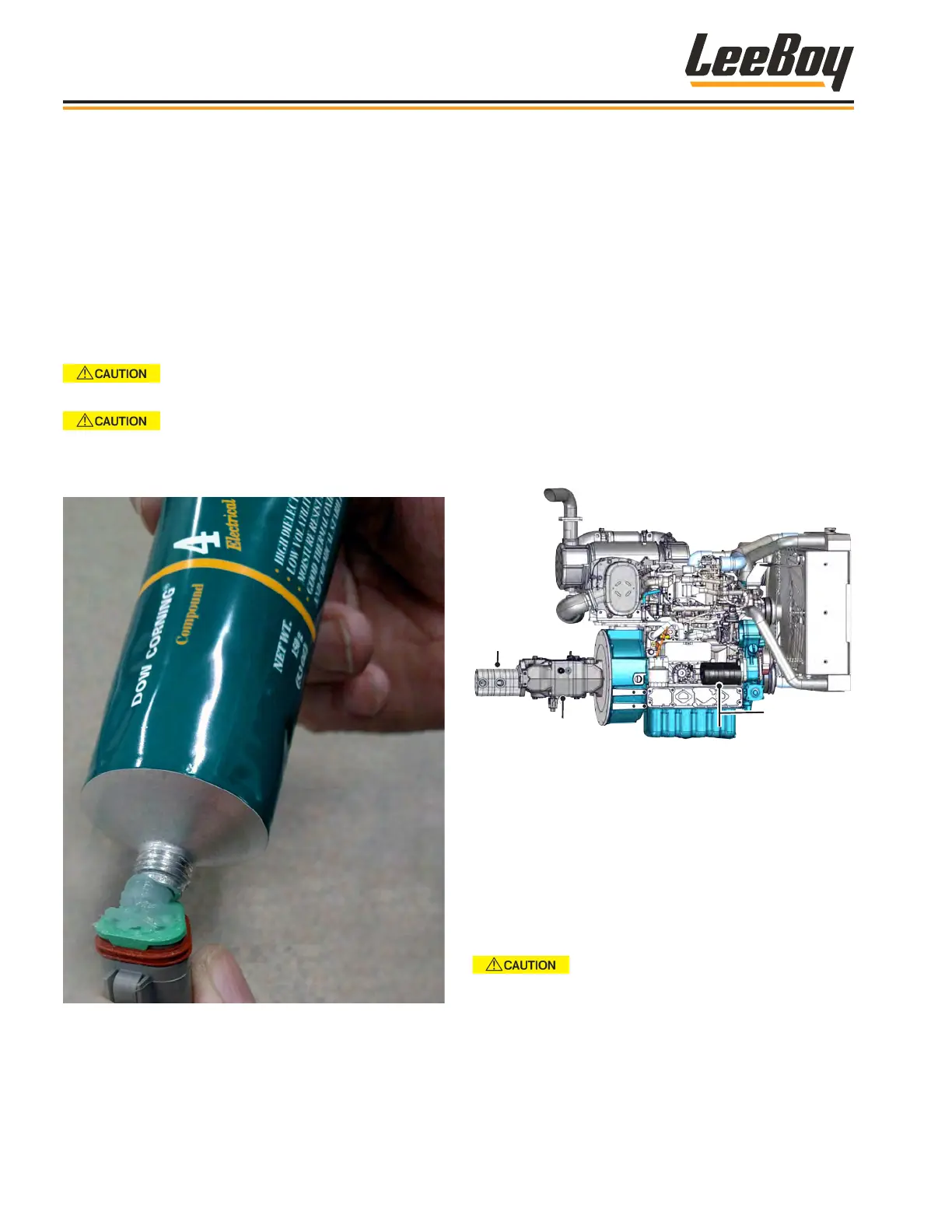

To correctly apply dielectric grease:

• Apply a thin, visible, uniform coat using ONLY high-

quality dielectric grease (Dow Corning 4 or equivalent)

across the MALE connector as shown in Figure 5-31.

• Coating too thin may not ll the gaps between

pins.

• Coating too thick may prevent proper

connection or force pins or seals out. (Figure

5-30)

• Plug in the male connector.

DO NOT force connector to lock if too

much grease has been applied.

Excessive grease application does

not allow a proper connection by preventing the

plugs from locking into place, and can cause damage

to the connector seals.

Figure 5-31. Incorrect Application of Dielectric

Grease

REPLACEMENT PROCEDURES

Gear PumpsGear Pumps

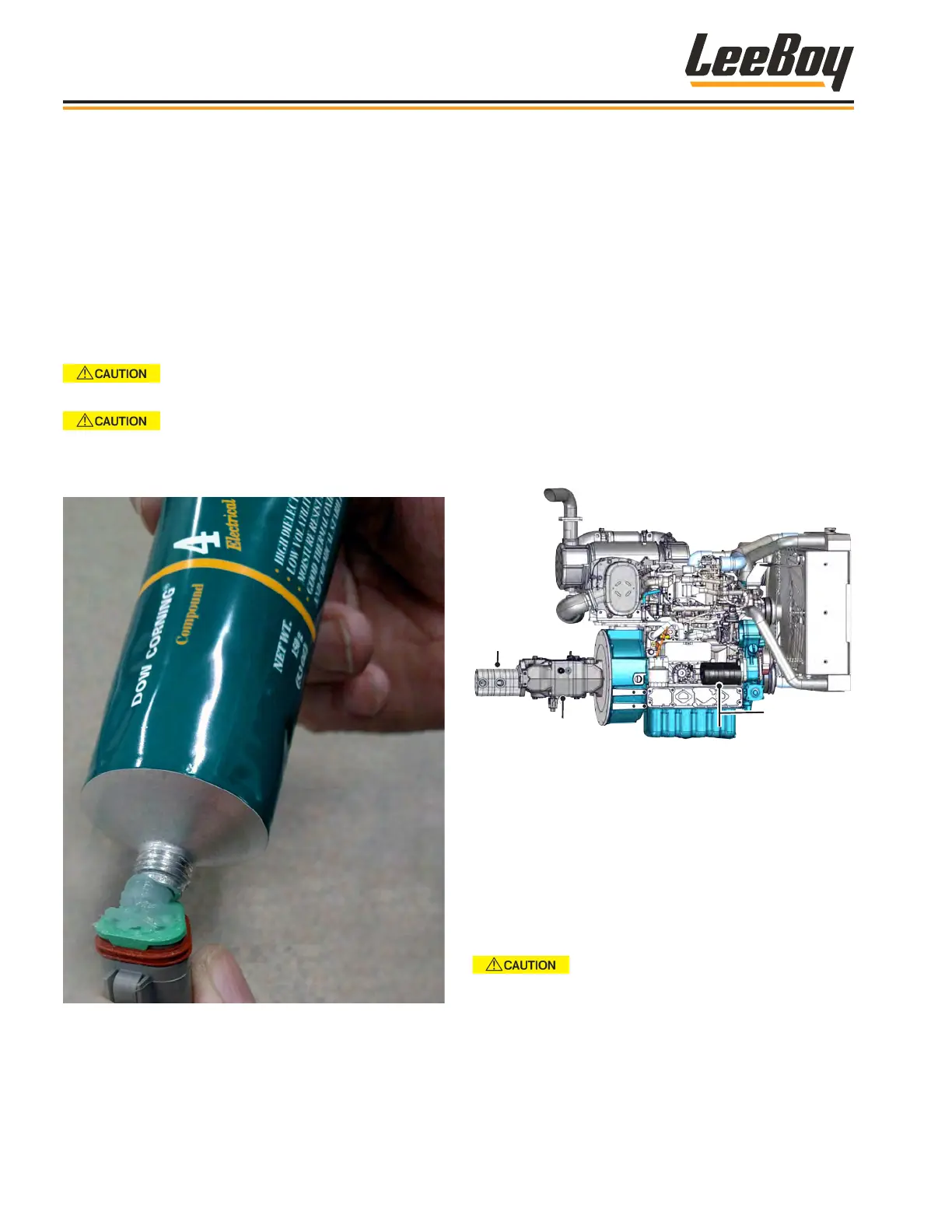

Hydraulic uid is transmitted throughout the machine to

motors and cylinders, becoming pressurized accord-

ing to the resistance present. The uid is controlled by

valves and distributed through hoses and tubes. Three

gear pumps play a signicant role in producing hydraulic

power as it supplies hydraulic uid to system compo-

nents: The tandem gear, tandem drive, and tandem

auxiliary gear pumps. (Figure 5-32)

The tandem gear and tandem drive pumps are

accessed via the left access panel. The tandem gear

pump is attached to the tandem drive pump (just behind

it). Both are easily reached via the right access panel.

The tandem auxiliary gear pump is easier to access

from the front access panel inside the hopper.

Tandem

Gear Pump

Tandem

Drive Pump

Tandem

Auxilliary

Gear Pump

Figure 5-32. Gear Pumps

Use the following procedure for replacing either of the

gear pumps:

1. Access the gear pump slated for replacement.

2. Label and disconnect the hoses to the gear pump,

capping the tting on the pump.

3. Label, plug and cap the hoses.

The gear pump assemblies are very

heavy and must be properly supported with a sling

before continuing the following steps. DO NOT

loosen mounting bolts unless the pump is sufciently

supported.

Loading...

Loading...