Steering and Speed ControlSteering and Speed Control

Use the dual joysticks for steering and speed control. It

is important to move the joysticks SLOWLY. Lift up on

the joystick collar and move joystick either FORWARD

or REVERSE. The joystick collar will lock back into

place in the NEUTRAL position. The RUN/STOP switch

applies parking brake when set to the STOP position.

(Figure 4-51 on the previous page.)

Be aware of the terrain and driving

conditions. Adjust speed accordingly.

NOTE: To slow the paver, move joysticks closer to

the neutral position.

NOTE: To stop the paver, pull joysticks back to the

neutral position.

• To drive the paver forward, lift up on the joysticks’

collar and push joystick forward to reach the

desired speed.

• To move in reverse, lift up on the joysticks’ collar

and move joystick backwards to reach desired

speed.

• Return joysticks to the neutral position to stop

paver.

• To steer the unit to the left, SLOWLY push the right

joystick farther forward than the left joystick. The

farther the joystick is pushed, the more the paver

turns. Slow and easy adjustments are required for

safe operation.

• To steer the unit to the right, SLOWLY push the left

joystick farther forward than the right joystick. The

farther the joystick is pushed, the more the paver

turns. Slow and easy adjustments are required for

safe operation.

NOTE: If the joysticks are in the forward position

and the Run/Stop switch is set to the STOP

position, the system will time-out after 30

minutes. You must put joysticks back into

neutral and toggle the Run/Stop switch from

RUN to STOP and back to RUN again to

regain control.

NOTE: If equipped with the optional steering wheel

control box: If the joystick steering function

is not being used, the Run/Stop switch must

be in the OFF position.

Before leaving the operator platform,

the operator must return joysticks to the neutral

position and switch the Run/Stop (on the Steering

and Speed Control Box) to the STOP position.

PAVER OPERATION

Spray DownSpray Down

Always spray down the machine to clean it before and

after paving. Spray solvent or release agent on any part

of the paver that comes into contact with asphalt to pre-

vent buildup that will damage the machine over time.

When using solvents and release

agents, DO NOT allow cleaning solvent to run onto

the ground. Only spray down the machine in a

designated area away from the paving site.

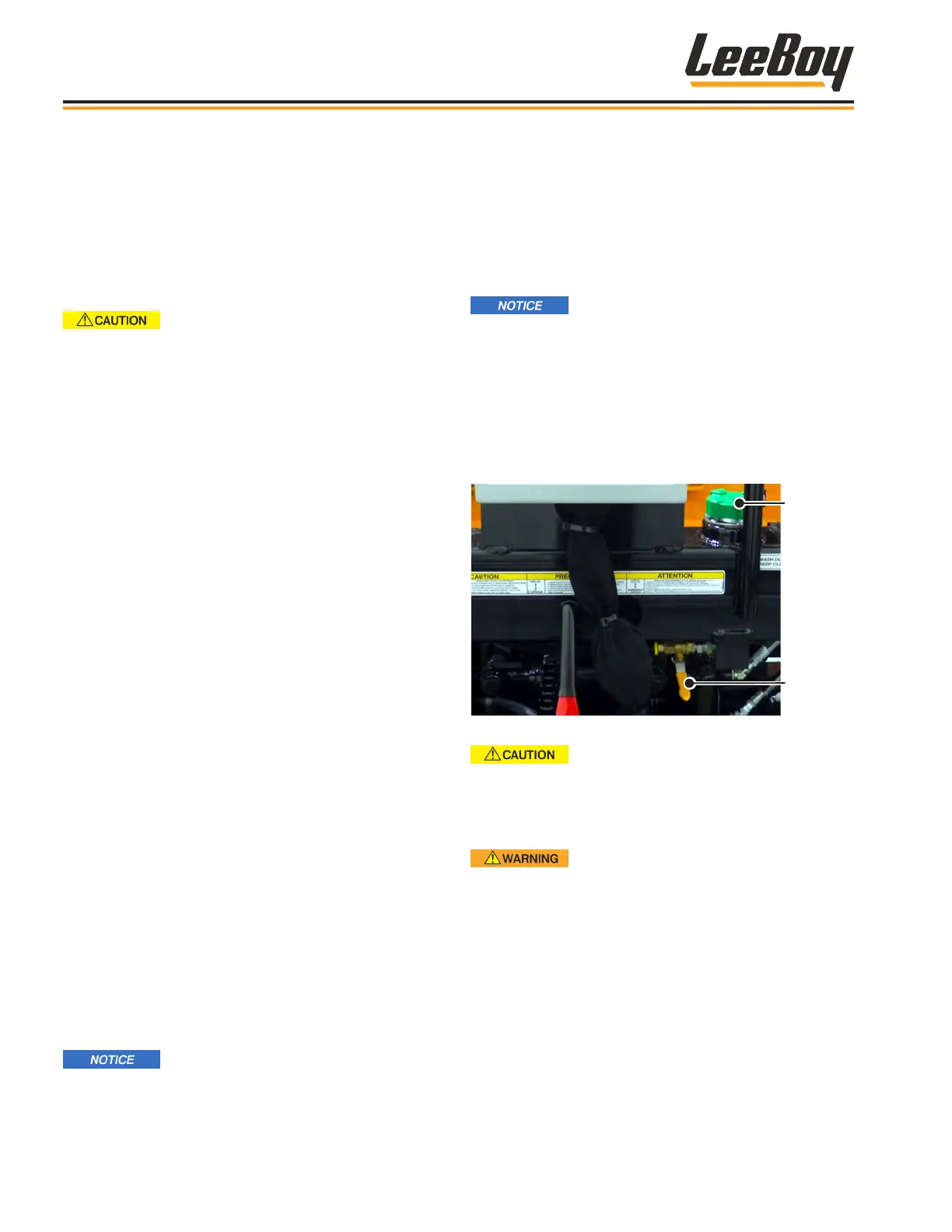

The green citrus tank ller cap is located on the screed

(right of the heat control box). The yellow valve lever is

just below the ller cap. (Figure 4-52) Turn the valve

clockwise to spray. Be sure to close the valve by turning

it counterclockwise when nished cleaning.

Filler Cap

Valve

Figure 4-52. Citrus Tank Filler Cap and Valve

Ensure the area is clear of others

and ammable materials before spraying. Allow the

screed to cool at least 10 minutes before spraying to

prevent possible burns from solvent spray on a hot

screed. The screed should be warm, but not hot.

Never spray cleaning solvent or

release agent near the screed heating element or

near open ame. These agents are highly ammable

and can ignite, causing serious personal injury.

• Ensure the area is clear of others before spraying.

• Open the hopper wings and raise the screed.

• Allow the screed to cool at least 10 minutes before

spraying to prevent possible burns from solvent

spray on a hot screed. The screed should be warm,

but not hot.

Operation

8608 Commercial Paver4-26

Loading...

Loading...