55

Maintenance

LeeBoy 8608 Commercial Paver 5-19

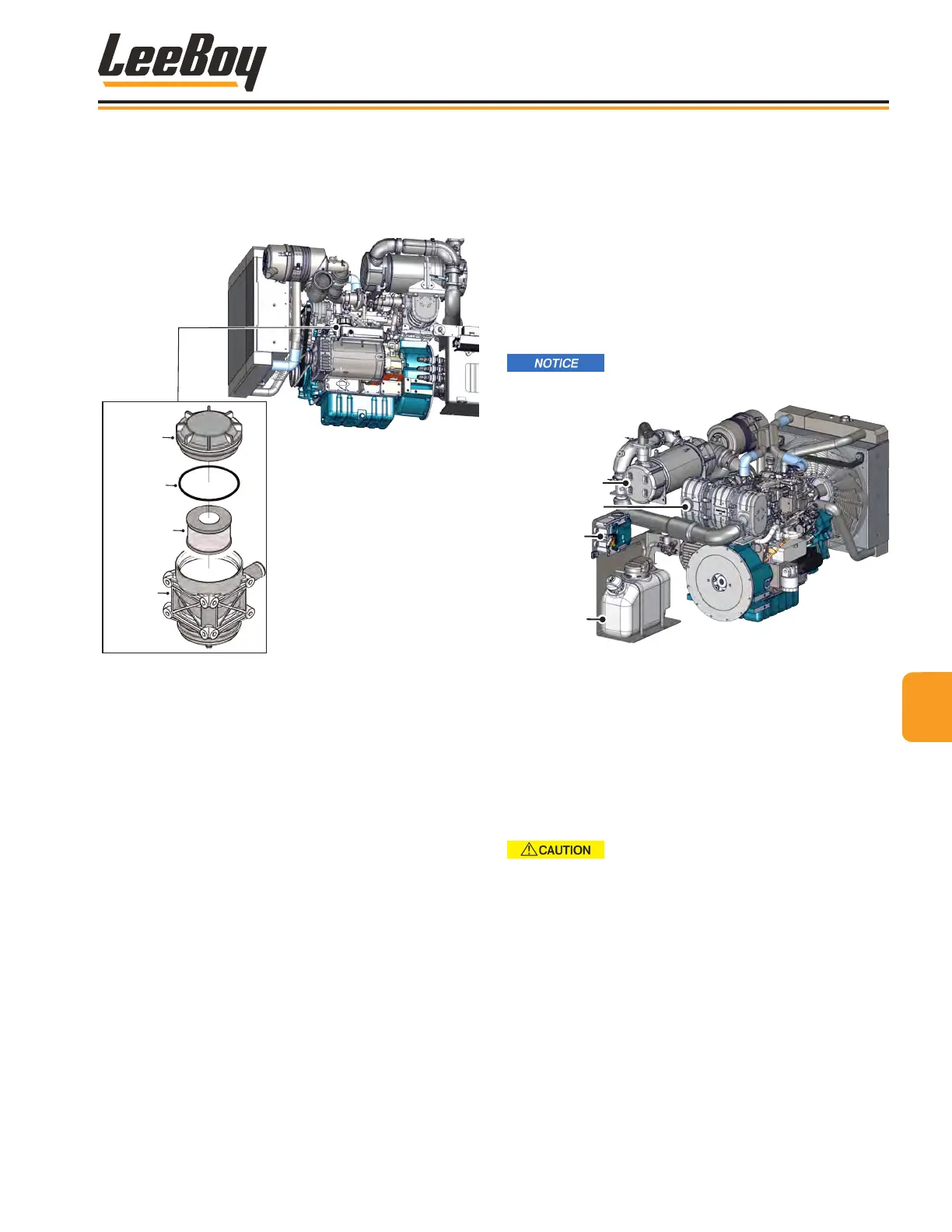

Change Oil Separator ElementChange Oil Separator Element

The oil separator captures oil mist carried over from the

lubrication process. The oil separator element must be

changed every 1500 hours of operation. (Figure 5-13)

Cap

O-Ring

Gasket

Element

Oil

Separator

Body

Replace the oil

separator element

every 1500 hours

of operation.

Figure 5-13. Oil Separator

To change the oil separator element:

1. Unscrew the oil separator cover cap and remove

from the body.

2. Remove the used gasket and lter element.

Dispose of in accordance with environmental laws

and requirements.

3. Wipe oil and grease off the oil separator body and

cover.

4. Insert a new lter element and gasket.

5. Reattach the cover cap to the oil separator body.

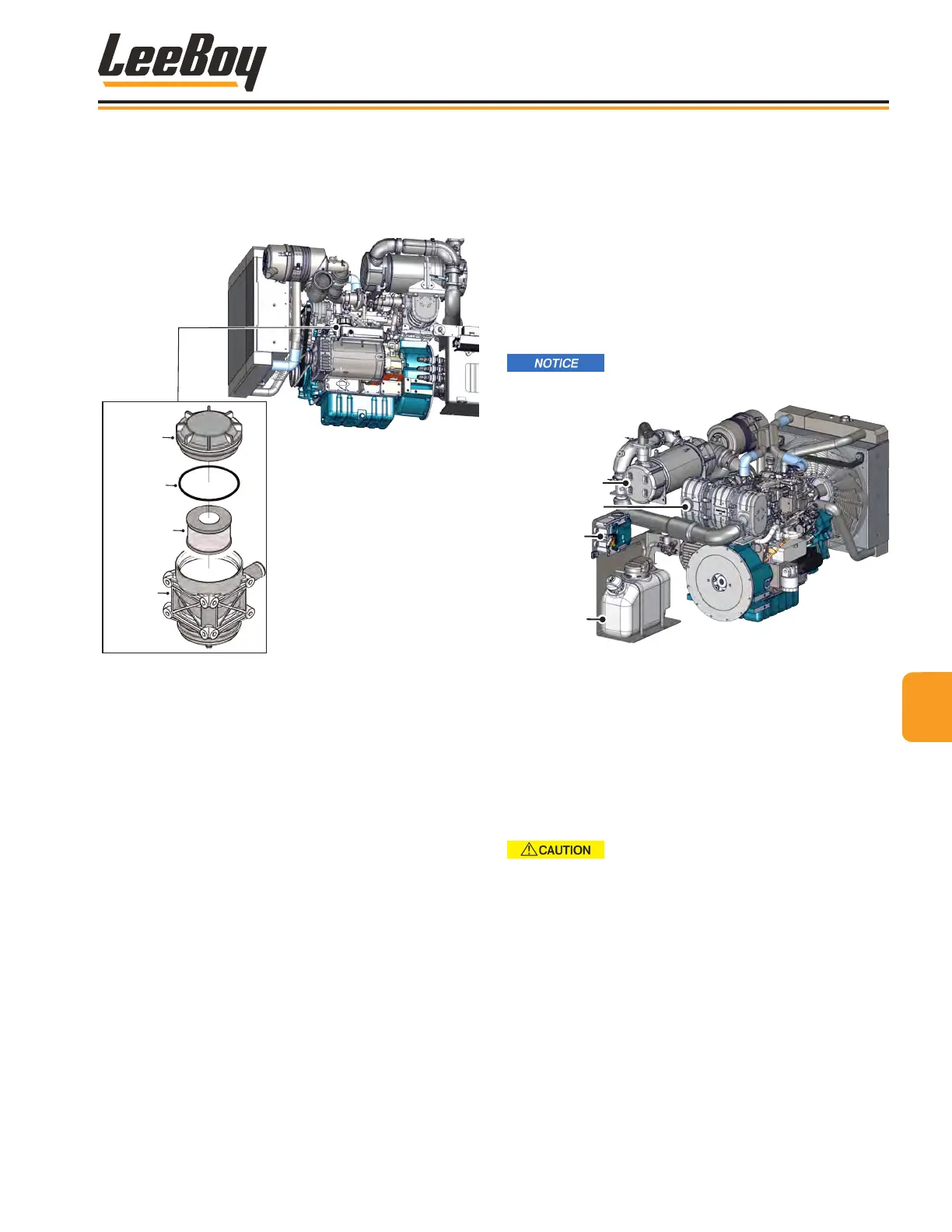

Selective Catalytic Reduction Selective Catalytic Reduction

(SCR) (SCR)

The SCR system is an efcient, effective means of

ltering contaminates for optimum engine performance

while reducing air pollution from exhaust emissions.

The SCR system precisely injects Diesel Exhaust Fluid

(DEF) into the engine’s exhaust system to transform

those toxic exhaust gases into harmless water vapor

and nitrogen. SCR technology is also cost-effective and

fuel-efcient. (Figure 5-14)

NEVER tamper with or remove any

emission-related component under penalty of law.

DEF Pump

DEF Tank

DPF

SCR

Figure 5-14. DEF Tank, Pump and DPF

A sensor on the Diesel Particulate Filter (DEF) tank

header monitors the uid level, temperature and quality

of DEF in the tank. The header is mounted on top of the

DEF tank and provides ltered DEF supply from the tank

to the DEF injector through the DEF pump.

NOTE: Check the ttings around the DEF tank header

for leaks or any signs of damage regularly. DEF

leaks will leave a white deposit around the ttings.

DO NOT pressure wash or steam

clean this unit to avoid damaging the components.

Use compressed air to remove any loose debris.

Loading...

Loading...