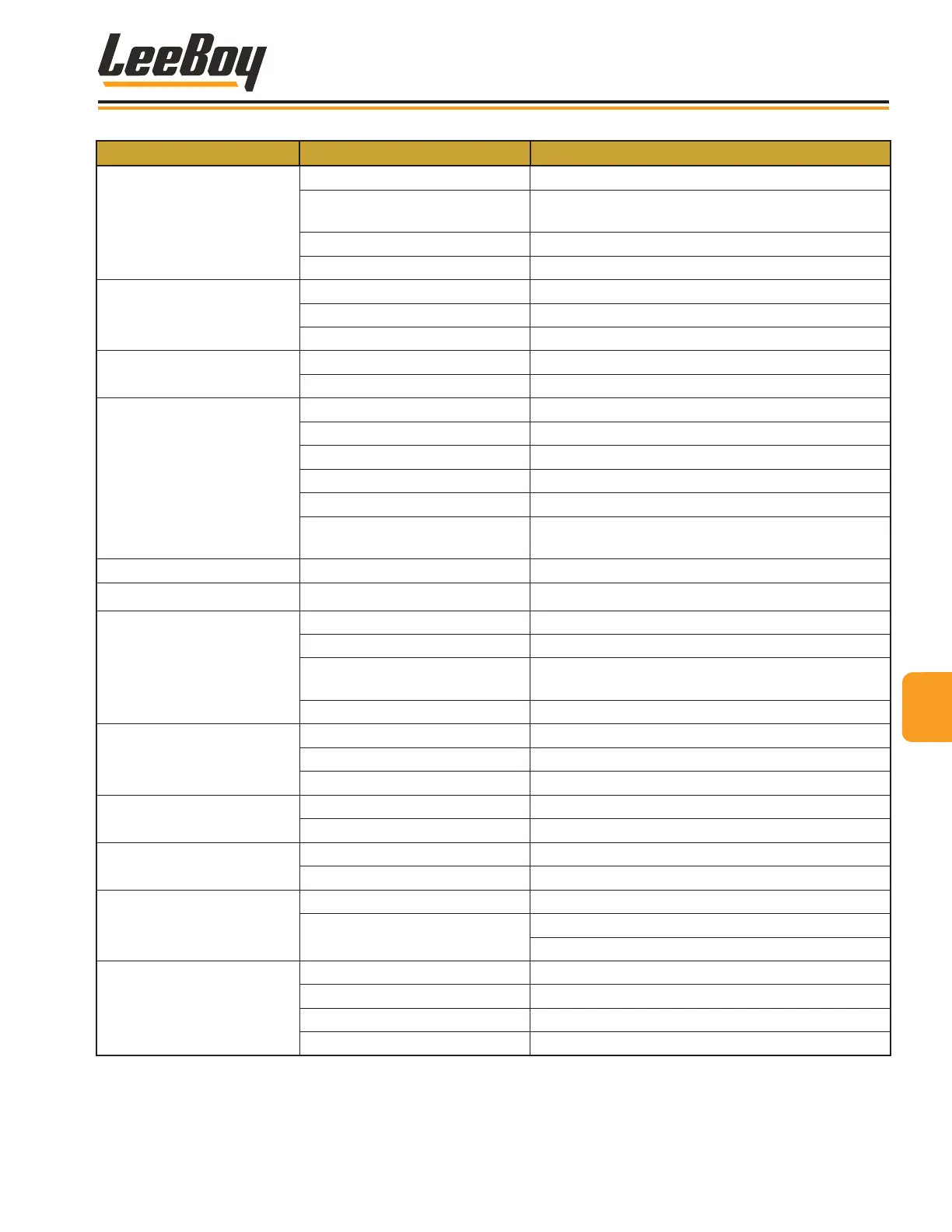

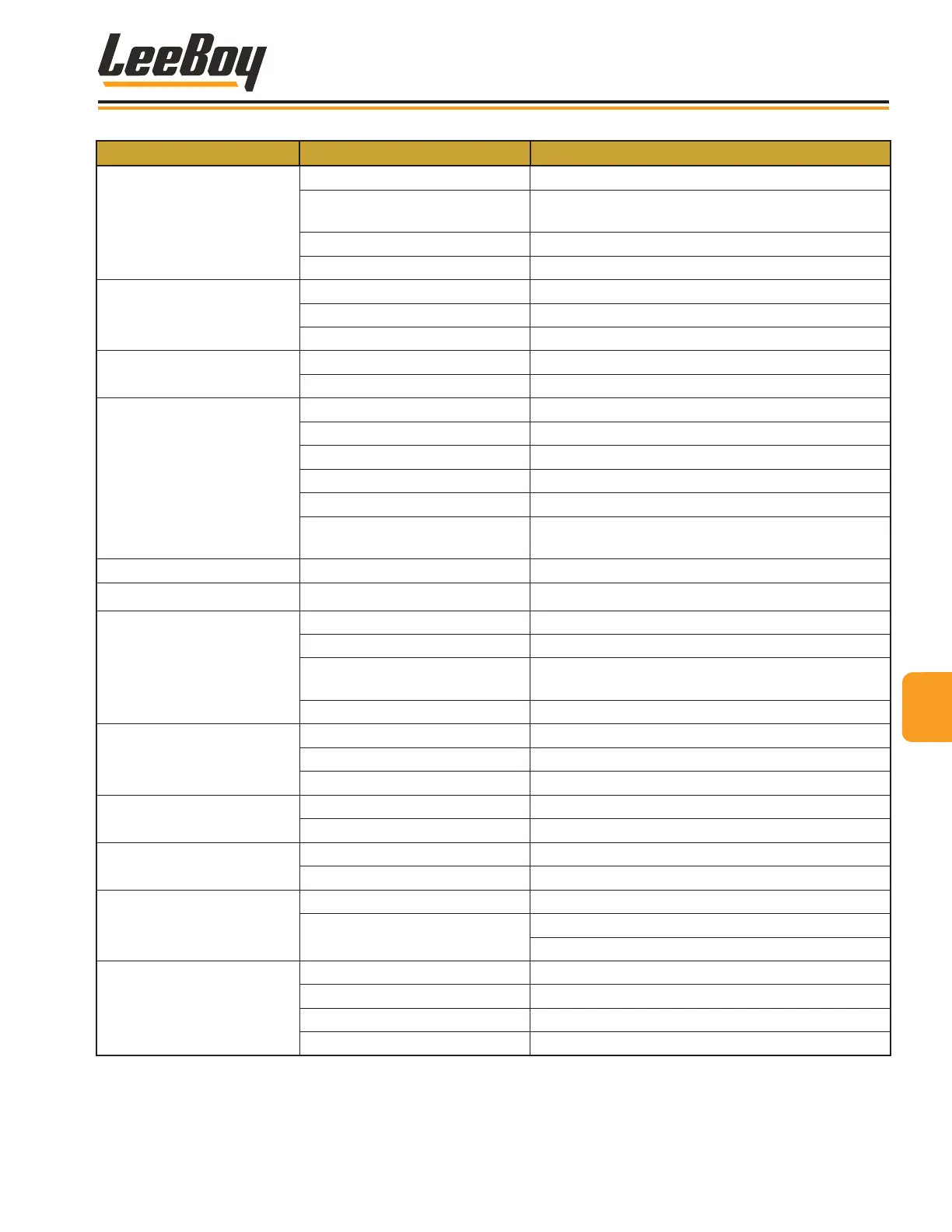

SYMPTOM CAUSE REMEDY

Tracks don’t operate

smoothly.

Tracks too loose. Tighten track pad bolts.

Engine RPM is too low to hold

track tension.

Rev engine to 1400 RPMs, then throttle back to 700

RPMs.

Track rollers worn. Replace.

Track tension pressure. Check tension pressure and relieve or adjust.

Machine will not pull on one

or both sides.

Faulty hydraulic motor. Replace.

Pump pressure too low. Check pump pressure and relieve or adjust.

Faulty torque hub. Rebuild or replace.

Engine runs but there is no

hydraulic pressure.

Pump drive coupling faulty. Replace.

Defective pump. Replace.

Auger not turning properly.

Drive chain is too loose. Adjust.

Drive chain broken. Replace.

Faulty motor. Replace.

Solenoid valve defective. Replace solenoid.

Asphalt buildup. Clean thoroughly and grease.

Overload of material to augers.

Set conveyor to proper speed in AUTO or use

paddles in MANUAL position.

Screed extensions binding. Asphalt buildup. Keep clean and greased.

Screed extension loose. Out of adjustment. Adjust hold-downs on extensions.

Screed leaving streak down

center of pavement.

No lead crown in screed Crown leading edge of screed.

Screed worn out or damaged. Replace.

Extensions set too low.

Adjust extension. Always begin operation with

extensions extended up with no down pressure.

Screed not heated properly. Check elements and heat control box.

Screed leaving ripples in

pavement.

Extension set too low. Readjust extensions.

Extensions work up and down. Adjust top guide.

Extension rod bushings worn. Replace bushings.

Flight screw locking up

Twisting screed too far. Give screed time to react.

Screw seized. Replace screw.

Flight screw bearing dam-

age.

Twisting screed too far. Give screed time to react.

Loading and unloading. Check ramps for easy access.

Hydraulic oil leaking from

breather cap.

Hydraulic oil tank overlled. Drain to proper ll level.

Oil overheated.

Slow paver down.

Check oil cooler and thermostat.

Hydraulic pump cavitation

or lost power.

Low level in hydraulic tank. Rell to proper level.

Clogged lters. Replace lters.

Suction hose loose. Retighten.

Charge pump worn. Rebuild or replace charge pump.

55

Maintenance

LeeBoy 8608 Commercial Paver 5-53

Loading...

Loading...