5

LeeBoy 8616B Conveyor Paver 5-5

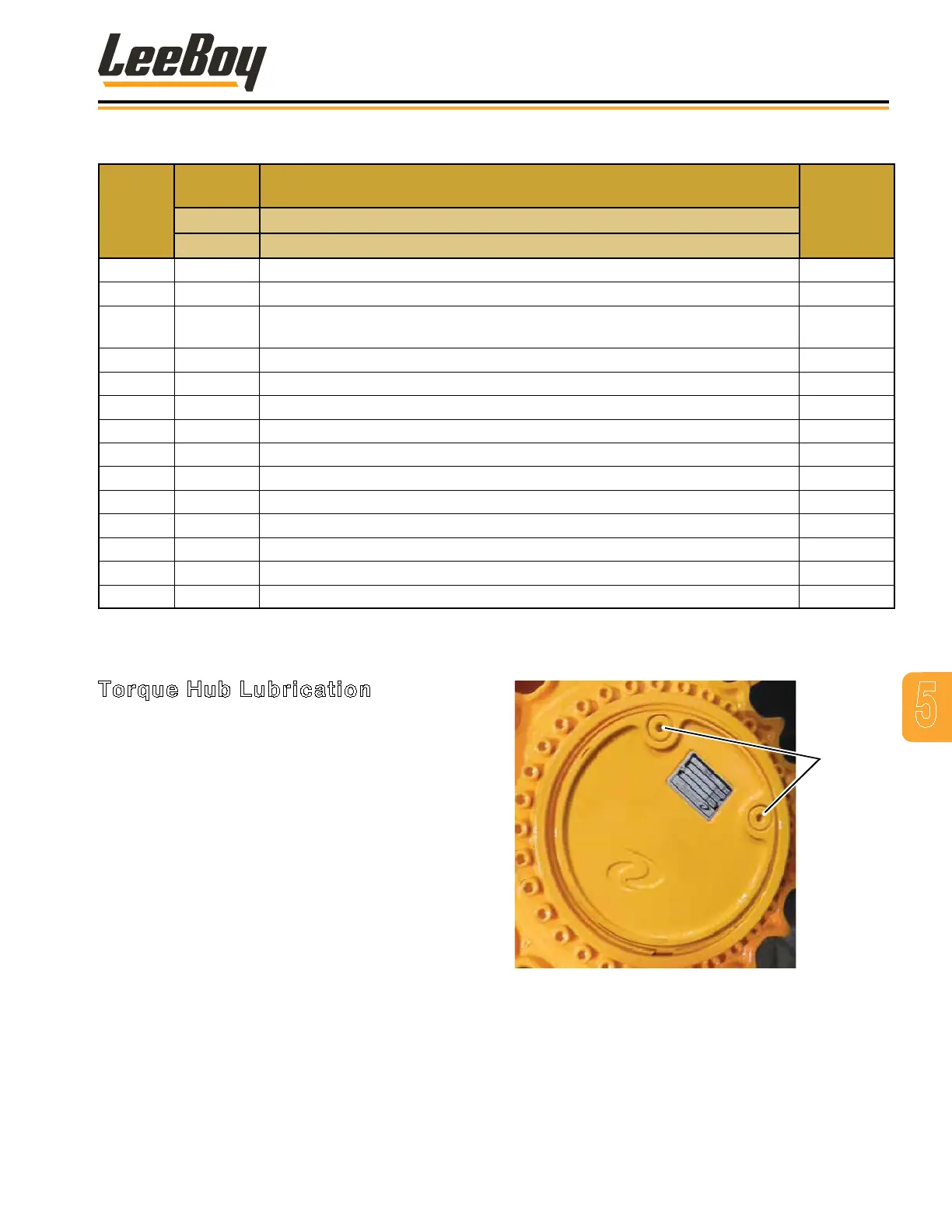

Table 5-2. Lubrication Points Schedule

ITEM

NO.

TYPE

LUBE

DESCRIPTION AND LOCATION

INTERVAL

A Grease With Shell Avania EP Grease 2 or Equivalent

B Spray with Release or Chain Lube Agent

1 B Conveyor chains and between track pads. Weekly

2 A Tilt screws. Weekly

3 A

Depth Screw. First grease in lock position, then unlock, turn 180° and grease

again).

Weekly

4 A Screed pivot. Weekly

5 A Slope cylinder pivot. Weekly

6 A All screws on screed extension and bearing. Weekly

7 A Extension slides. Weekly

8 B Cut-off pivot at augers. Daily

9 A Grease auger tting on end mount. Daily

10 B Conveyor and auger. Daily

11 B Auger chains. Daily

12 A Main ight screw components. Weekly

13 A Rear auger bearings. Quarterly

14 B Front and rear conveyor idler and drive tubes. Monthly

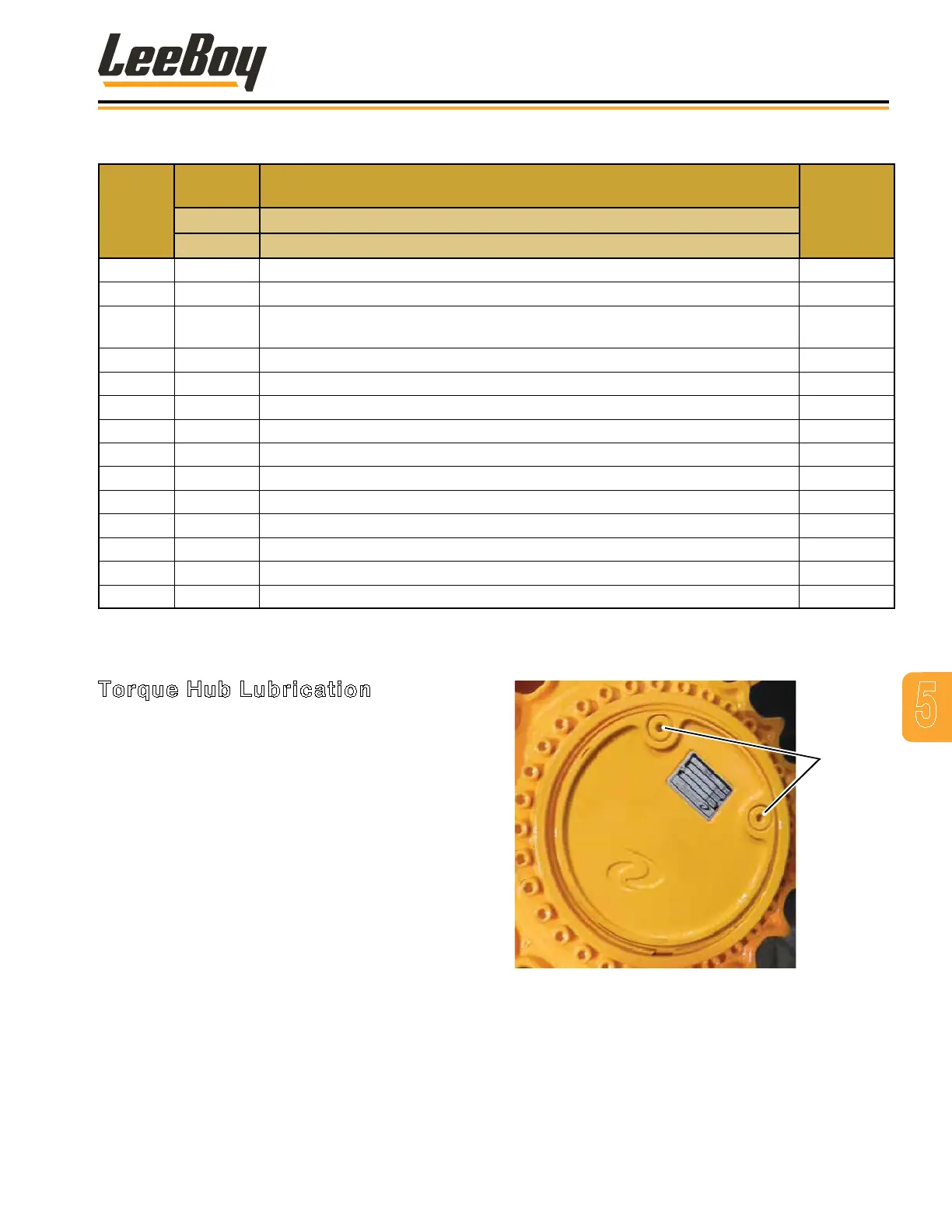

Torque Hub Lubrication

1. Position the torque hub so that either of the plugs

are at the 3 o’clock position. (Figure 5-2)

2. Remove the plug at the 3 o’clock position rst. If oil

comes out, no oil is needed. Insert plug and tighten.

3. If oil does not come out, remove the plug at the 12

o’clock position and ll torque hub with 80W-90

gear oil until oil starts to appear at the other hole.

4. Replace both plugs and repeat process on other

torque hub.

Figure 5-2. Torque Hub Plugs

Loading...

Loading...