LeeBoy 8616B Conveyor Paver5-10

Track Tension

The hydraulic adjustment cylinders are automatic and

provide even tension on the tracks to prevent excessive

wear to the paver’s undercarraige.

This feature requires the operator to maintain at least

a three-quarter throttle setting when backing with a

loaded hopper to maintain the proper track adjustment.

Failure to maintain adequate throttle

setting can result in poor performance or damage to

the machine.

Track tension is controlled by a load-sense pump that

operates all cylinders. The track tension is set on the

main manifold located at the hopper end of the electrical

valve manifold.

Pressure Check

The track hydraulic pressure is set at 1200 PSI at the

track tension main manifold.

Too much track tension pressure

will cause premature wear on the chains, idler and

sprockets.

To check pressure:

1. Connect a 3000 PSI gauge to the gauge port on the

manifold.

2. Start engine, setting engine to 1400 RPM and

observe gauge. Pressure should read 1200 PSI.

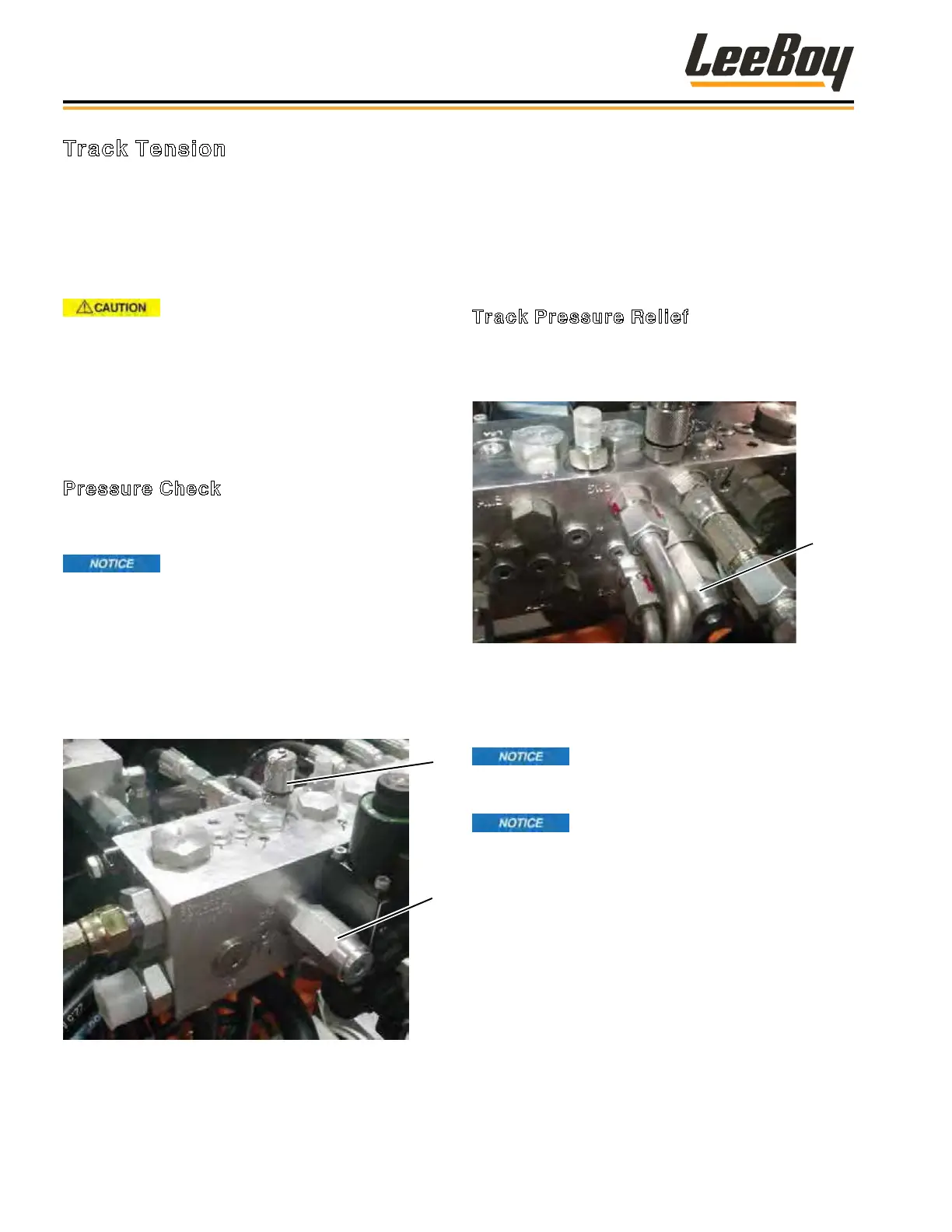

1

Figure 5-8. Main Manifold

1 - Gauge Port

2 - Pressure-Reducing Valve

3. If adjustment is needed, locate the pressure-

reducing valve on left side of main manifold. (Figure

5-8)

4. Remove valve cap with an allen wrench.

5. Adjust the pressure-reducing valve clockwise for

more tension or counterclockwise for less tension.

Track Pressure Relief

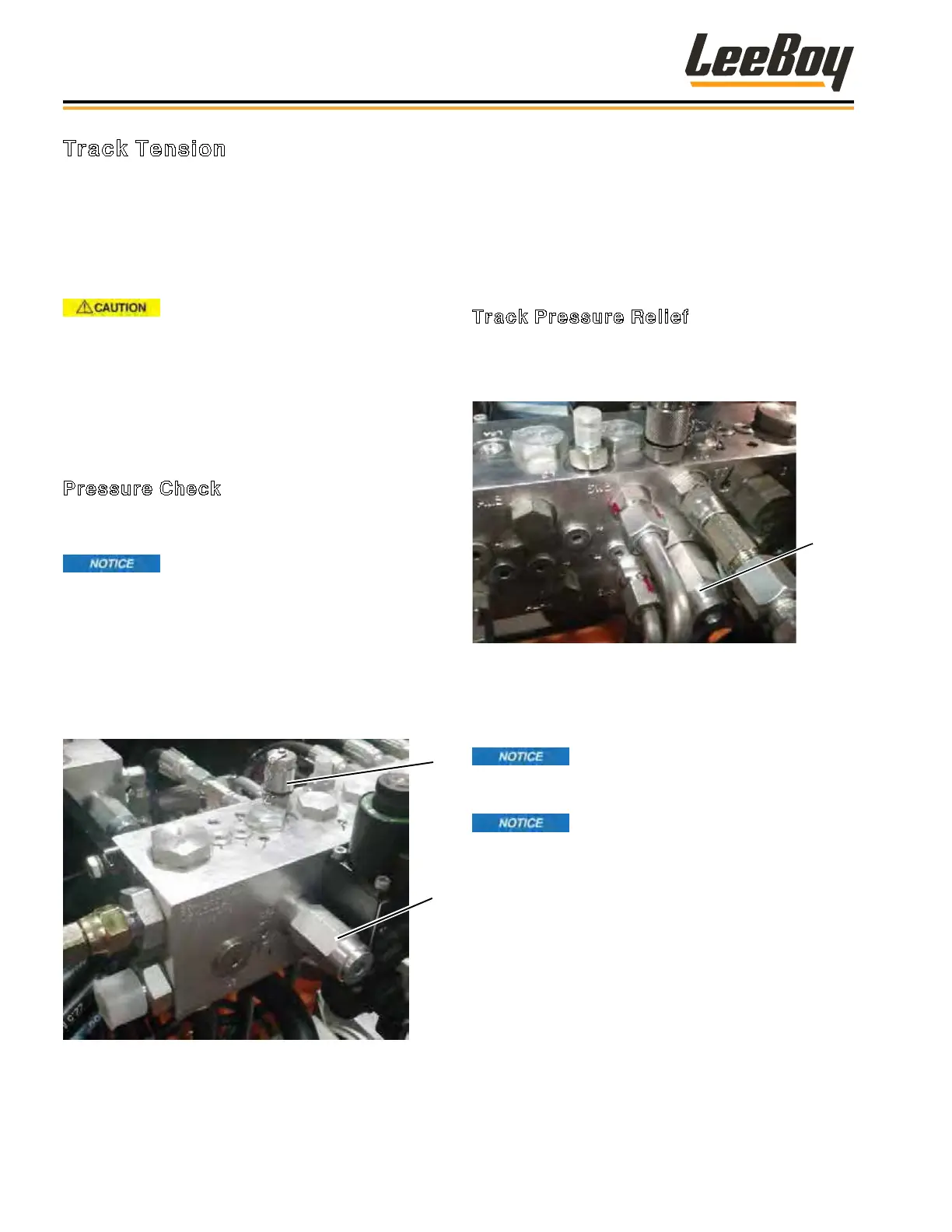

Relieving track tension pressure is set to 2300 PSI. The

pressure-relief valve is located on opposite side of the

main manifold. (Figure 5-9)

Pressur

Relief

Valve

Figure 5-9. Main Manifold

1. Remove valve cap with an allen wrench.

2. Adjust the pressure-relief valve clockwise for more

tension or counterclockwise for less tension.

DO NOT screw the pressure-relief

valve adjuster below 1200 PSI or all pressure will be

lost to the hydraulic tank, causing a heat problem.

You will need to “deadhead” a cylinder

function to reach the 1200 PSI level.

Loading...

Loading...