5

LeeBoy 8616B Conveyor Paver 5-7

Every 250 Hours or Quarterly

Routine Maintenance

1. Replace fuel lter. (Page 5-19)

2. Change engine oil and lter. (Page 5-17)

3. Change the hydraulic oil and charge lter. (Page

5-20)

4. Perform previous routine maintenance and any

other engine preventive maintenance described in

the Engine Operator’s Manual.

Every 500 Hours or Semi-Annual

Routine Maintenance

1. Replace coolant.

2. Change air lter and replace if needed. (Page 5-18)

3. Change torque hub oil. (Page 5-5)

4. Perform previous routine maintenance and any

other engine preventive maintenance described in

the Engine Operator’s Manual.

Every 1000 Hours or Annual

Routine Maintenance

1. Replace strainers in the hydraulic tank. (Page 5-21)

2. Perform previous routine maintenance and any

other engine preventive maintenance described in

the Engine Operator’s Manual.

MAINTENANCE ADJUSTMENTS

Certain components of the paver need adjustments

for optimum performance, operation and general

maintenance.

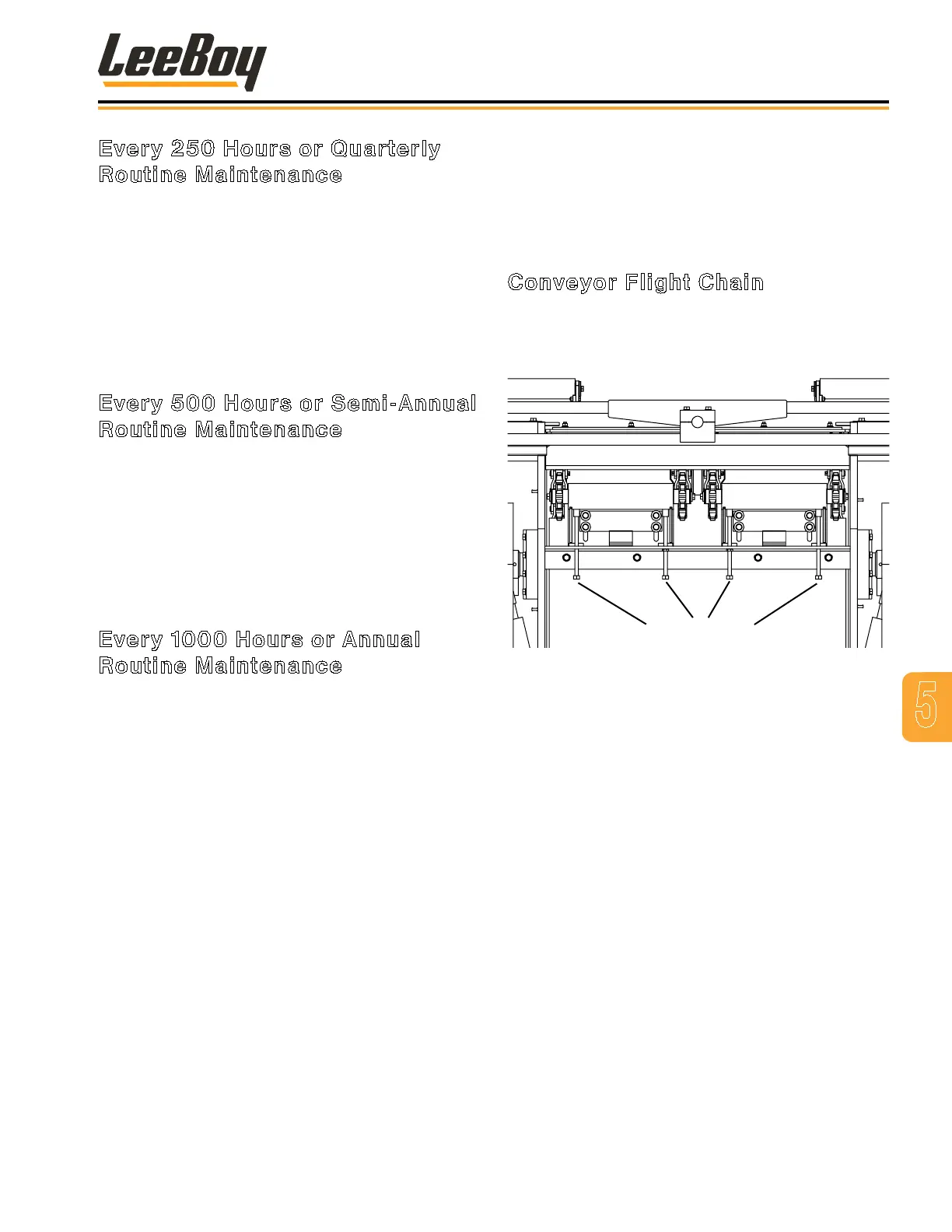

Conveyor Flight Chain

The conveyor ight chains must be adjusted every 100

hours. If irregular movement of the conveyor occurs, an

adjustment is needed regardless of the time interval.

Adjustment Bolts

Figure 5-3 Conveyor Flight Chain Adjustment

Use the following procedure to make this adjustment on

both sides of the conveyor:

1. Move front of paver onto a ramp.

2. Loosen the jam nuts in front of the adjustment bolts.

(Figure 5-3)

3. Turn each adjustment bolt alternately the same

amount. For example, turn one bolt one half turn,

then the other bolt one half turn, etc.

4. Continue alternating tightening until the ight

chains are tight. (The pressure on the chain will be

noticeable as the bolts are tightened.)

NOTE: Drag chains should be 1/2-inch away from

rear frame channel.

5. After the conveyor chain tension is set, retighten

locknuts and bolts holding the ight chain assembly.

6. Repeat steps 1 through 4 for the opposite side.

7. Grease front and rear conveyor tubes at grease

blocks on each side of conveyor.

Loading...

Loading...