262335 121 Revision A

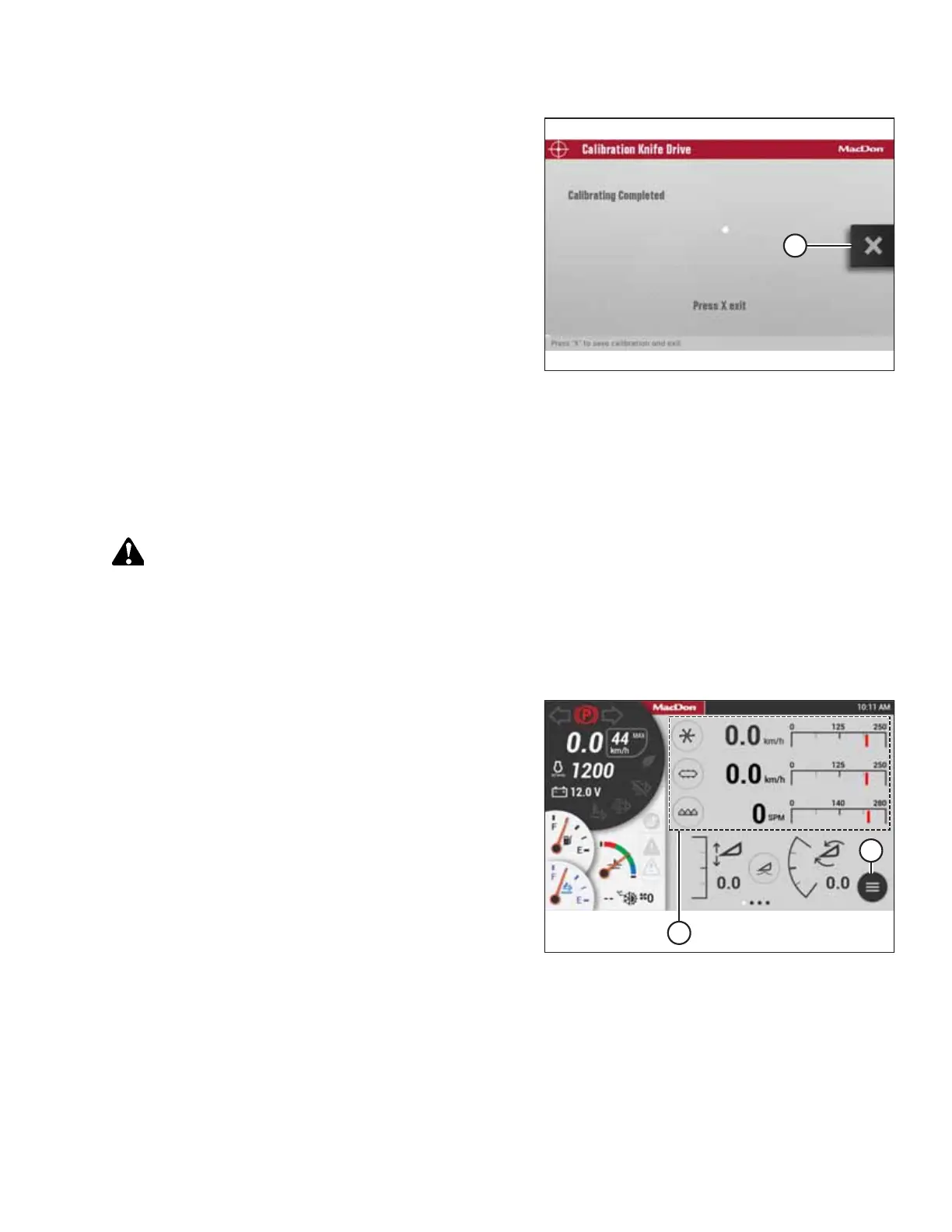

Figure 5.51: Knife Drive Calibration Page

8. When the calibration is complete, press X icon (A) to save

the calibration and exit the page.

NOTE:

This calibration procedure can also be done when the

machine is in normal operation; however, this will result in

more erratic knife speeds. Performing a deliberate

calibration prior to normal operation will make sure that

the calibration is automatically maintained and adjusted as

performance varies. This also ensures that the system

constantly or periodically monitors the relationship of the

engine speed, the knife speed, the valve current, and the

pressure.

5.14.2 Calibrating Knife Drive on HarvestTouch

™

Display

When a header is attached to the windrower, the windrower’s HarvestTouch

™

Display will recognize the header ID and

choose the appropriate settings for that header. Before it can be operated, however, the header’s knife drive must be

calibrated to ensure that the knife drive pump output is accurate.

DANGER

Ensure that all bystanders have cleared the area.

NOTE:

This calibration MUST be performed with the engine running and the header engaged.

1. Start the engine.

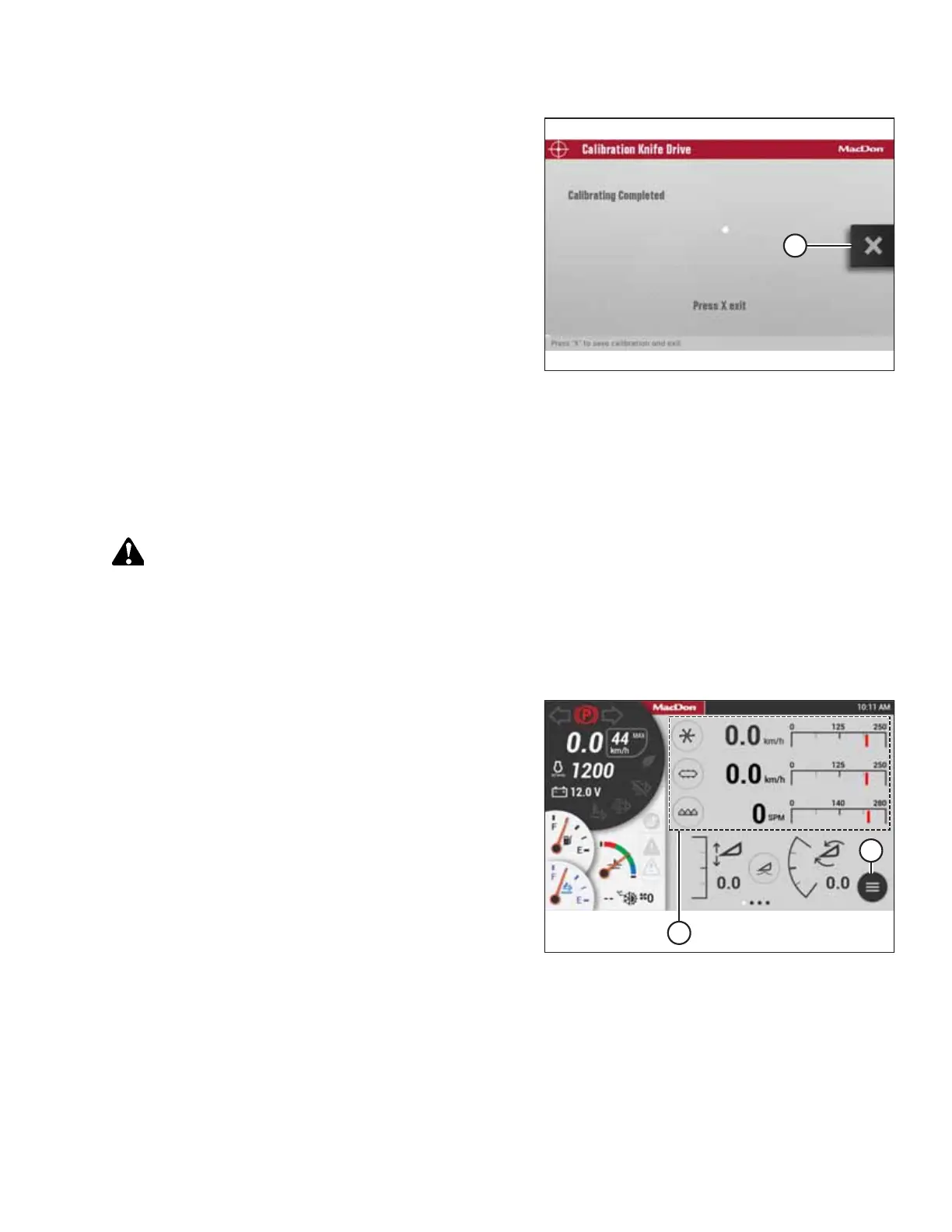

Figure 5.52: HarvestTouch

™

Display

2. Engage the header.

NOTE:

Once the header is engaged, header gauges (A) will appear

on the HarvestTouch

™

Display home page.

3. Select MENU icon (B).

PERFORMING PREDELIVERY CHECKS

Loading...

Loading...