Recommended Fluids and Lubricants

Your machine can operate at top efficiency ONLY if clean lubricants are used.

• Use clean containers to handle all lubricants.

• Store in an area protected from dust, moisture, and other contaminants.

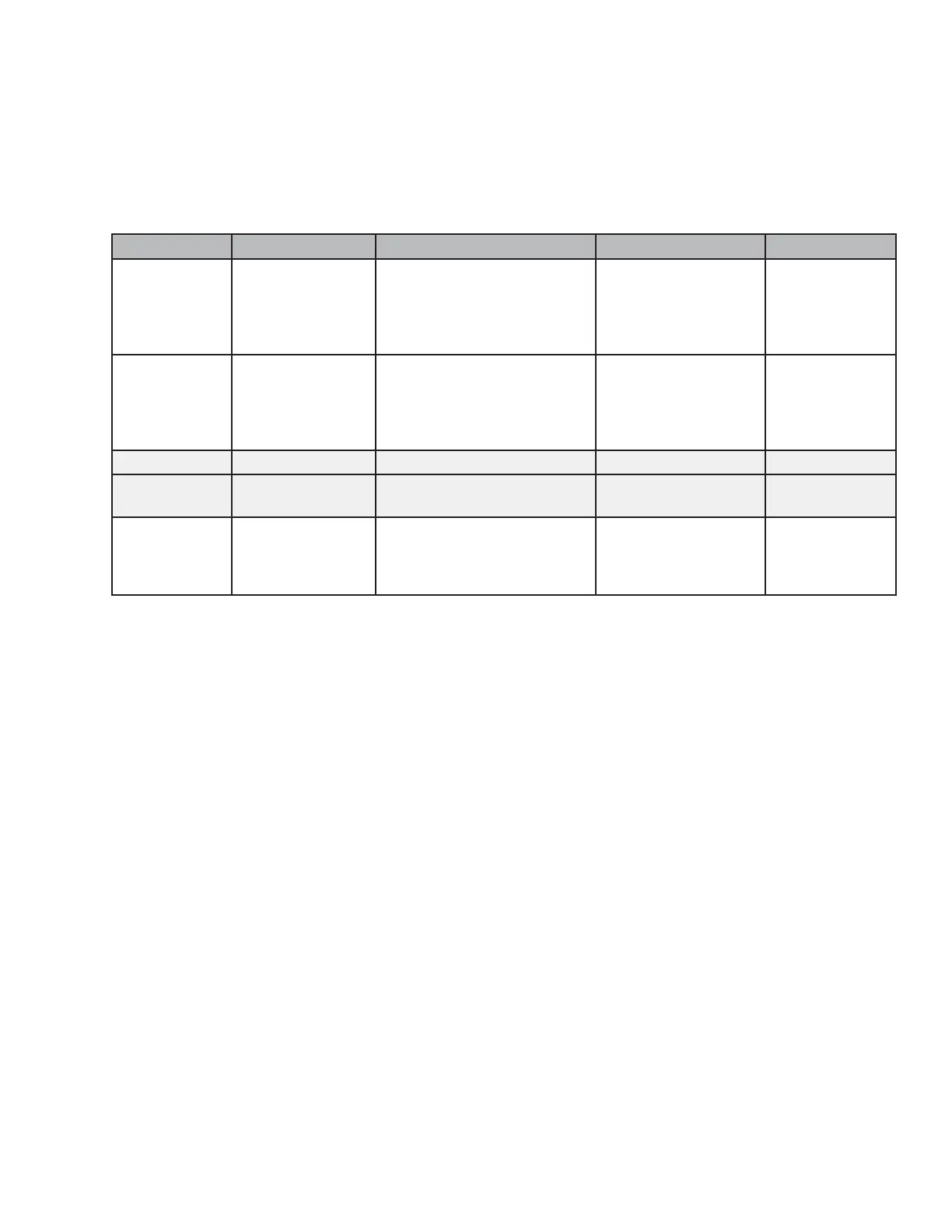

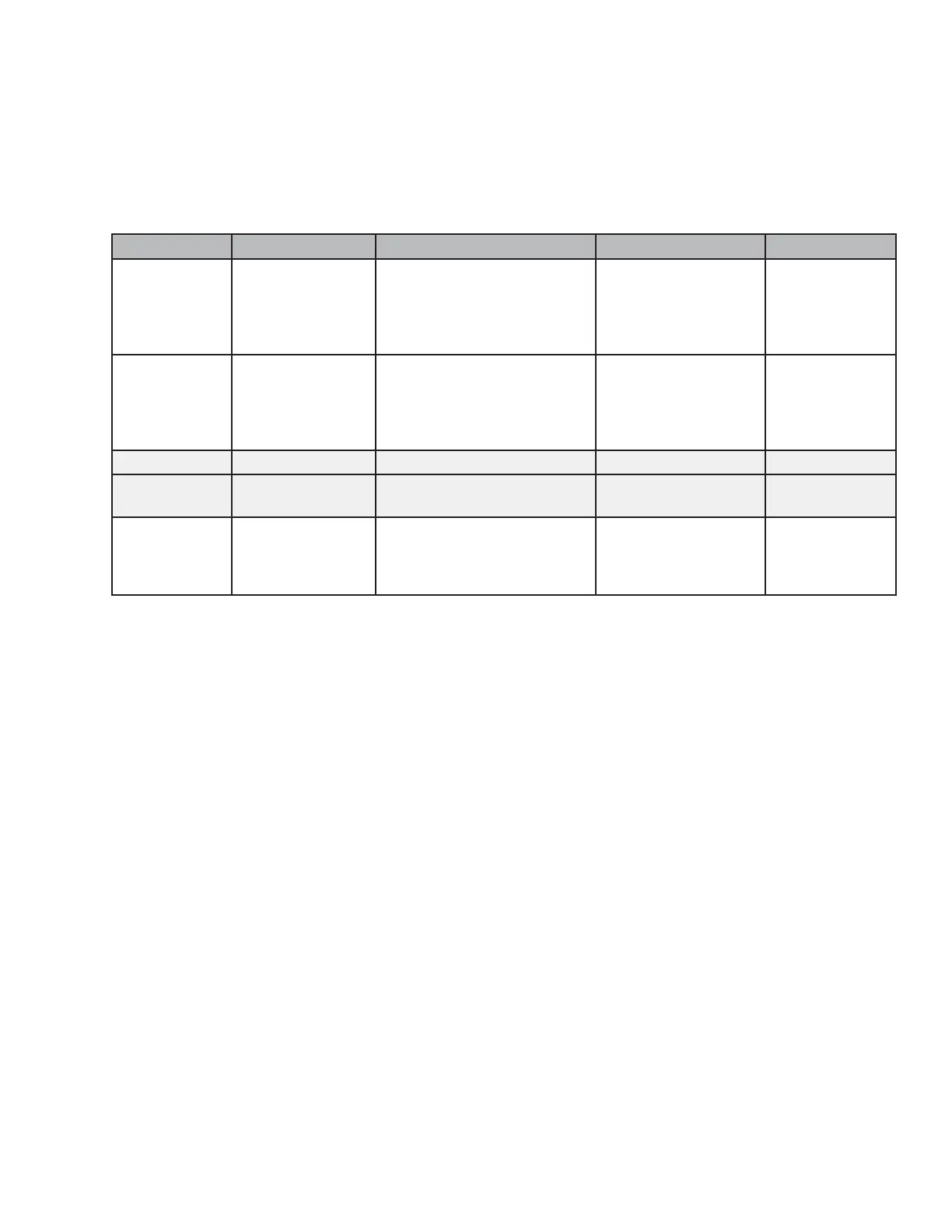

Lubricant

Specification

Description

Use

Capacities

Grease

SAE Multi-Purpose

High temperature extreme

pressure (EP2) performance

with 1% max molybdenum

disulphide (NLGI Grade 2).

Lithium base.

As required unless

otherwise specified

—

Grease

SAE Multi-Purpose

High temperature extreme

pressure (EP) performance with

10% max molybdenum

disulphide (NLGI Grade 2).

Lithium base.

Driveline slip-joints

—

Gear lubricant

SAE 85W-140

API service class GL-5 Knife drive box

2.1 L (2.2 US qts)

Gear lubricant

SAE 85W-140

API service class GL-5

Conditioner drive

gearbox

1 L (1.06 US qts)

Hydraulic oil

SAE 15W-40

Compliant with SAE specs for

API class SJ And CH-4 engine oil.

Steering, lift, and

header drive systems

reservoir

126 L (33 US gal)

Loading...

Loading...