262335 145 Revision A

Predelivery Checklist

Perform these checks and adjustments prior to delivery to your Customer. If adjustments are required, refer to the

appropriate page number in this manual. The completed checklist should be retained by either the Operator or the Dealer.

CAUTION

Carefully follow the instructions given. Be alert for safety-related messages that bring your attention to hazards and

unsafe practices.

Header Serial Number:

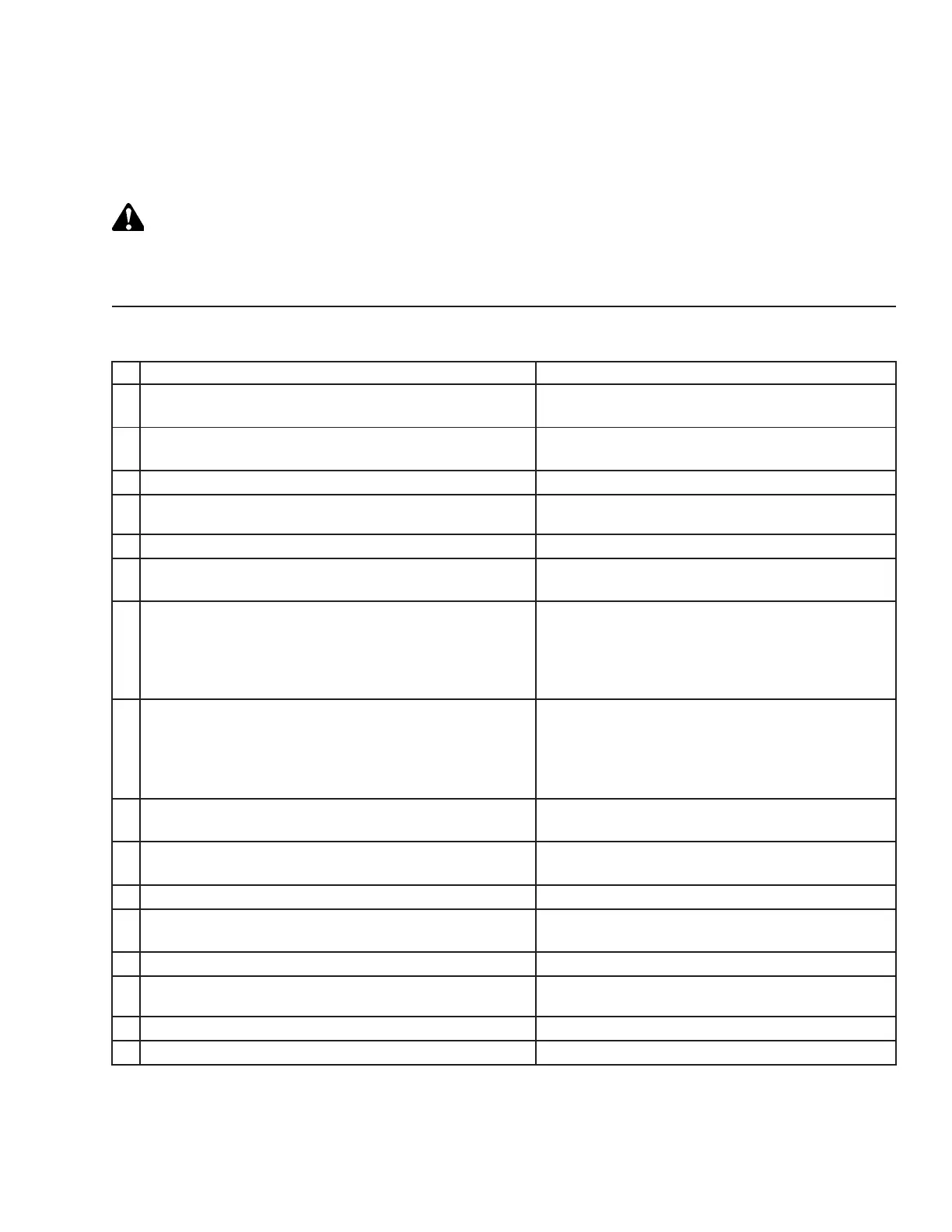

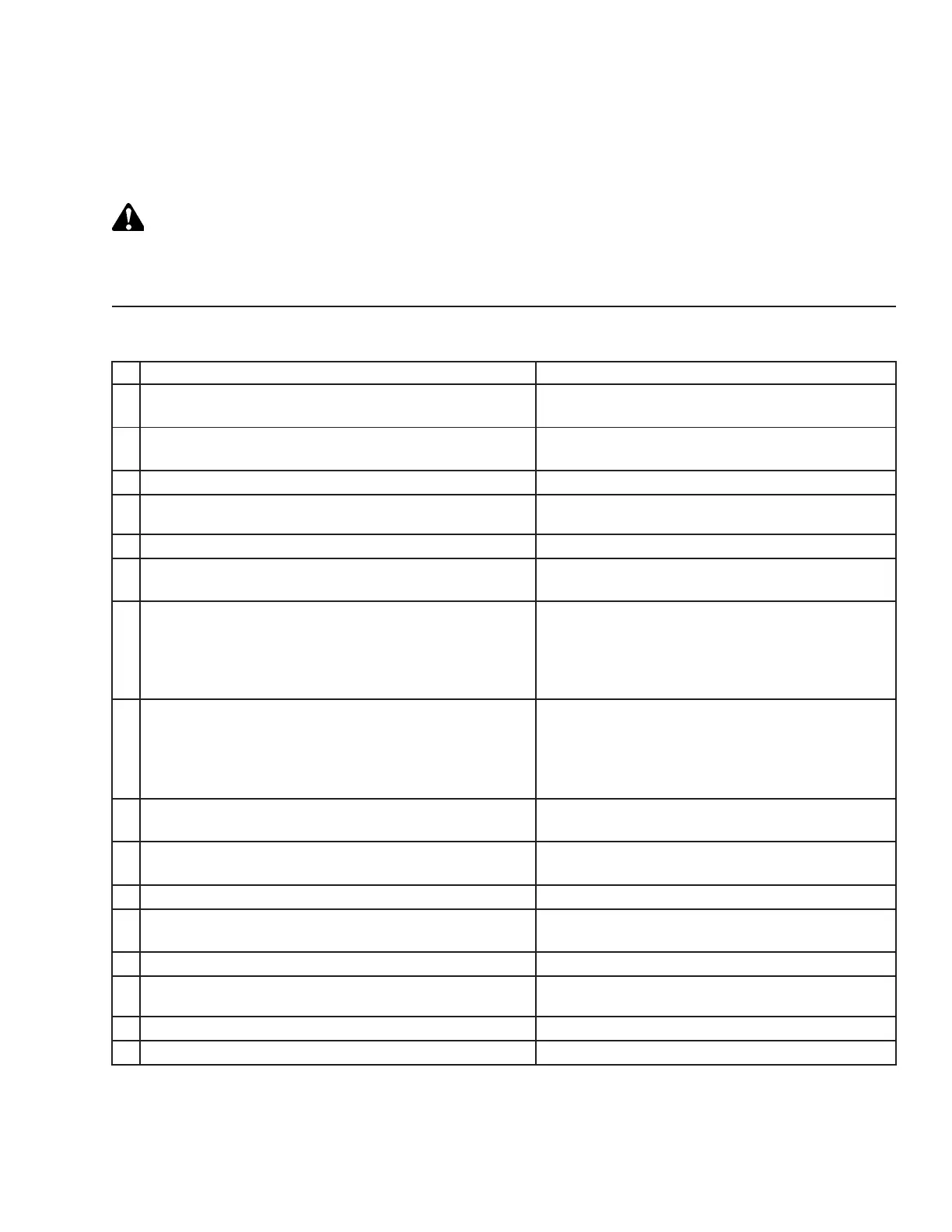

Table .17 A40D, A40DX Predelivery Checklist

üü

Item

Reference

Check for shipping damage or missing parts. Be sure all

shipping dunnage is removed.

—

Check for loose hardware. Tighten to required torque if

applicable.

Check knife drive belt tension.

5.1 Checking Drive Belts and Chains, page 95

Check reel tine to header pan and knife clearance.

5.3 Checking Reel Tine to Header Pan Clearance, page

97

Check auger stripper bar clearance. 5.2 Checking Auger Stripper Bar Clearance, page 96

If mechanical link, set header angle to middle of

adjustment range for first use.

—

Check that header is level.

• 5.7 Leveling the Header – M Series Windrower,

page 108

• 5.8 Leveling Header – M1 Series Windrower, page

110

Check header float: 335 –380 N (75–85 lbf).

• 5.4 Checking and Adjusting Float – M Series Self-

Propelled Windrowers, page 98

• 5.5 Checking and Adjusting Float – M1 and M2

Series Windrowers, page 99

Check lean bar is adjusted to a setting appropriate for

first crop.

3.7 Adjusting Lean Bar, page 24

Check skid shoes are evenly adjusted at a setting

appropriate for first crop.

5.12 Checking Optional Skid Shoes / Gauge Rollers,

page 117

Check knife drive box lube level and breather position. 3.20 Repositioning Knife Drive Box Breathers, page 88

Check that rear and side forming shields are evenly set to

desired position.

3.10 Assembling Forming Shield, page 28

Grease all bearings and drivelines. 4 Lubricating the Machine, page 89

Check conditioner gear case lube level.

5.11 Checking Oil Level in Conditioner Gearbox , page

116

Check conditioner roll gap, timing, and alignment. 5.10 Checking Conditioner Rolls, page 114

Check roll intermesh hardware is securely tightened. 5.10 Checking Conditioner Rolls, page 114

Loading...

Loading...