214327 122 Revision B

5.3 Maintenance Requirements

Regular maintenance is the best insurance against early wear and untimely breakdowns.

Periodic maintenance requirements are organized according to service intervals.

When servicing the machine, refer to the appropriate section in this chapter and use only the fluids and lubricants specified

in Recommended Fluids and Lubricants on the inside back cover.

Log hours of operation, use the maintenance record, and keep copies of your maintenance records (refer to 5.3.1

Maintenance Schedule/Record, page 122).

CAUTION

Carefully follow safety messages. Refer to 5.1 Preparing Machine for Servicing, page 119 and 1 Safety, page 1.

5.3.1 Maintenance Schedule/Record

Maintenance requirements are organized according to service intervals.

If a service interval specifies more than one timeframe, e.g., "100 hours or annually", service the machine at whichever

interval is reached first.

IMPORTANT:

Service the machine more often if operating under adverse conditions (severe dust, extra heavy loads, etc.).

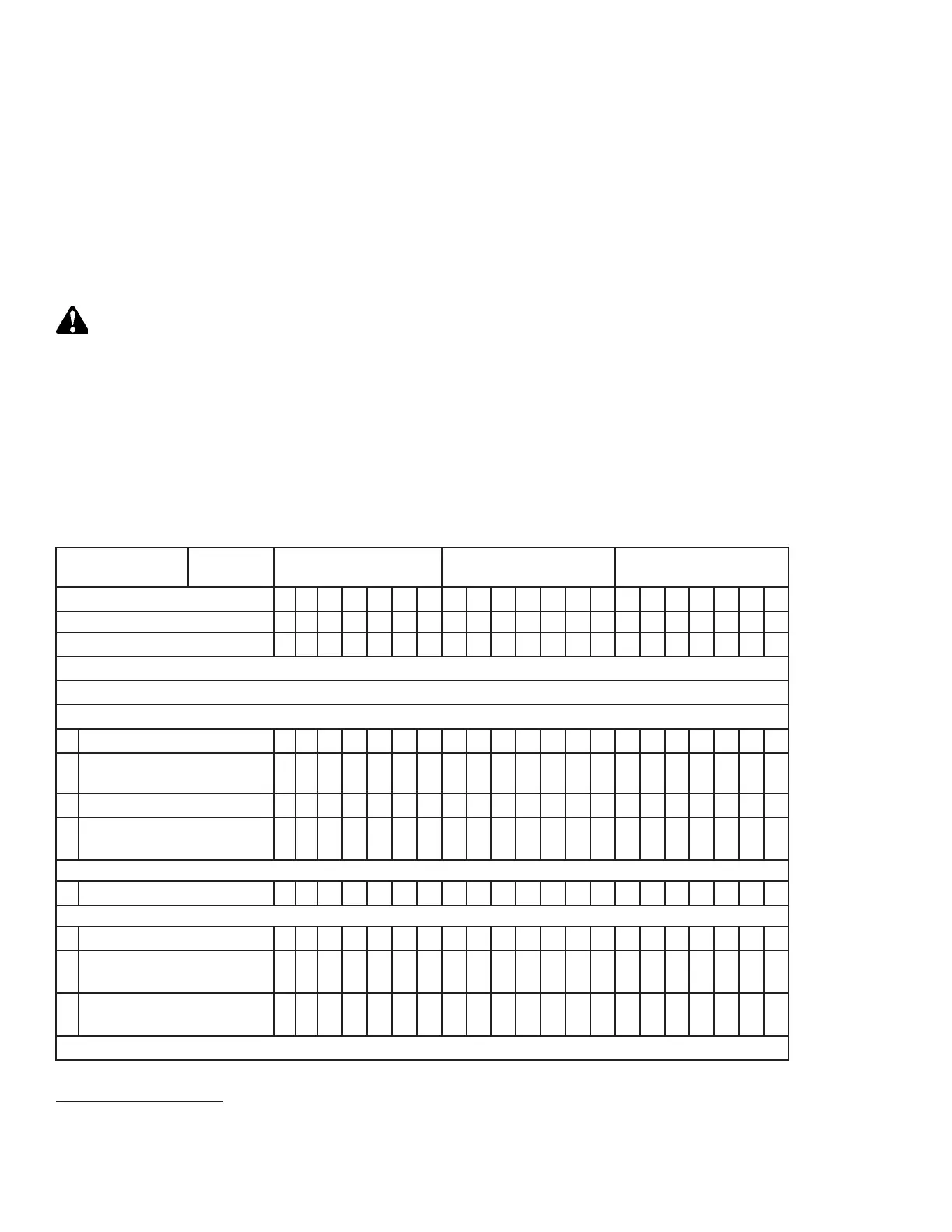

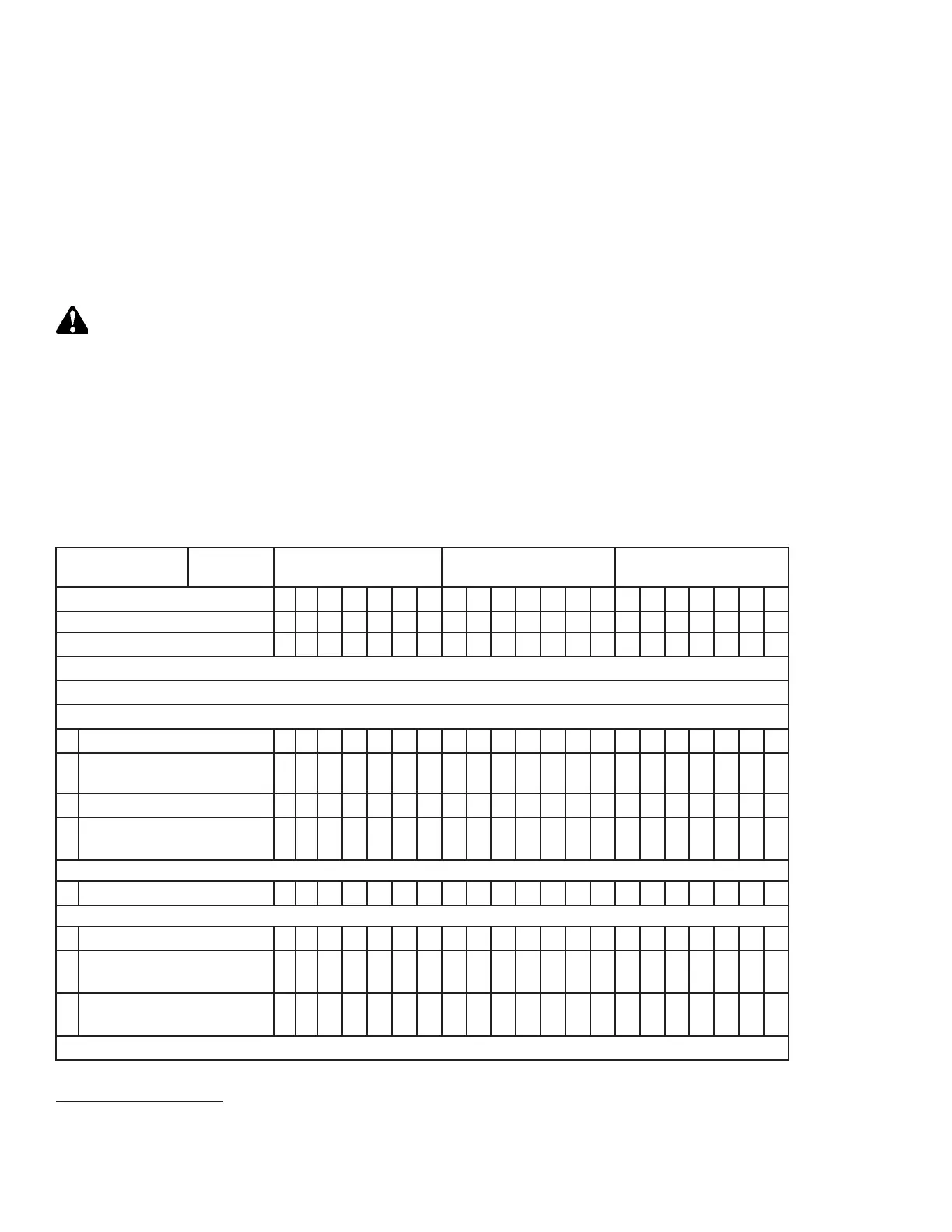

Maintenance

Record

Action:

üü - Check

SS - Lubricate

▲▲ - Change

Hour Meter Reading

Date

Serviced by

First Use, refer to 5.3.2 Break-In Inspection, page 123

End of Season, refer to 5.3.4 Maintaining the Header – End-of-Season, page 124

10 Hours or Daily

46

ü

Hydraulic hoses and lines

47

ü

Knife sections, guards, and

hold-downs

47

ü

Tire pressure

47

S

Knife (except in sandy

conditions)

47

25 Hours

S Knifehead(s)

47

50 Hours

ü

Draper roller bearings

▲

Knife drive box oil - first 50

hours only

S

All upper cross auger (UCA)

grease points

100 Hours or Annually

46

MAINTENANCE AND SERVICING

46. Whichever occurs first.

47. A record of daily maintenance is not required, but can be kept at the Owner’s/Operator’s discretion.

Loading...

Loading...