214327 142 Revision B

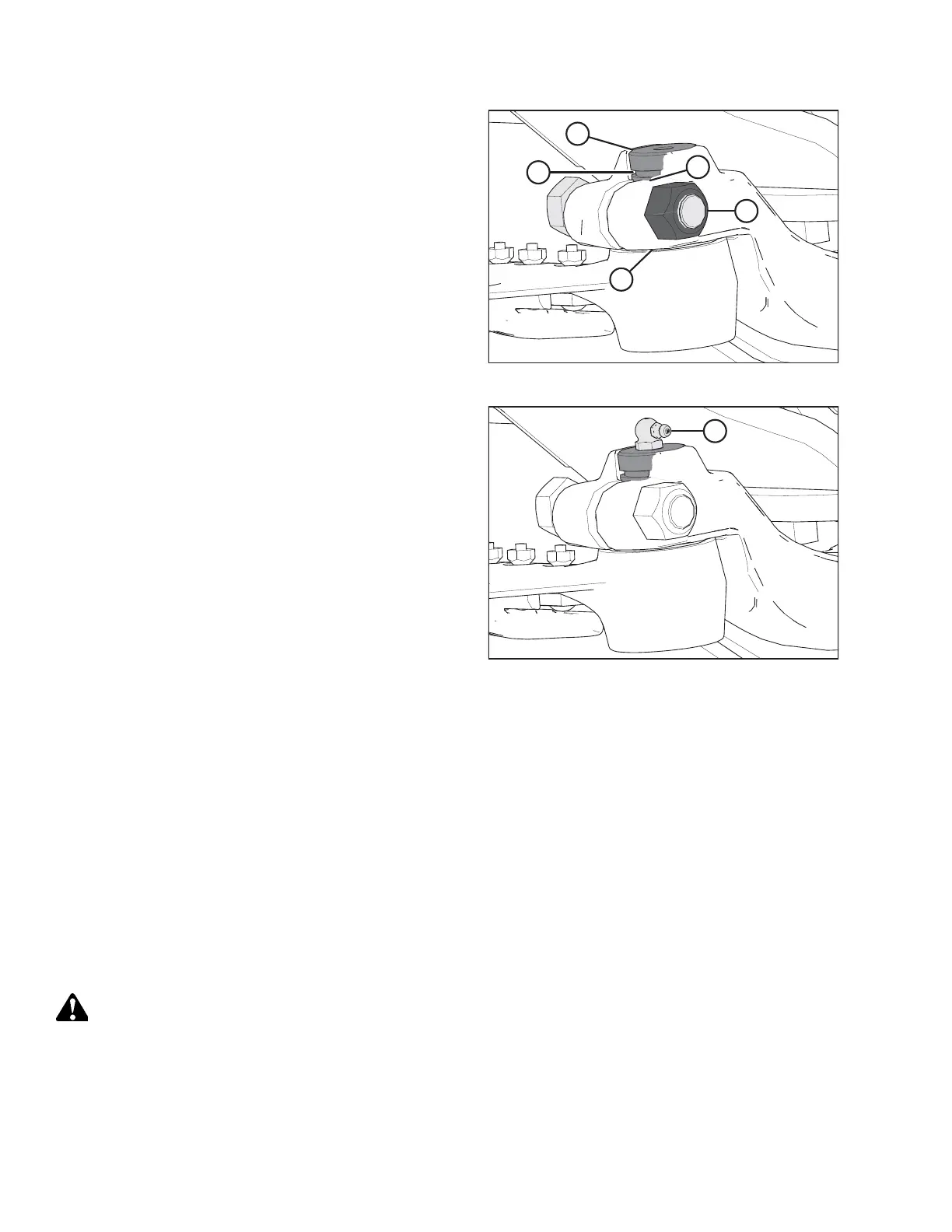

Figure 5.31: Knifehead

6. Install knifehead pin (A) through the output arm and into

the knifehead. Tap knifehead pin (A) down, and make sure

the pin is seated at the bottom of the knifehead.

7. Set groove (B) in the knifehead pin 1.5 mm (1/16 in.) above

output arm (C). Secure it with 5/8 in. x 3 in. hex head bolt

and nut (D), and torque the hardware to 217 Nm

(160 lbf·ft).

8. Using a feeler gauge, check that the gap at location (E) is

0.25 mm (0.01 in.).

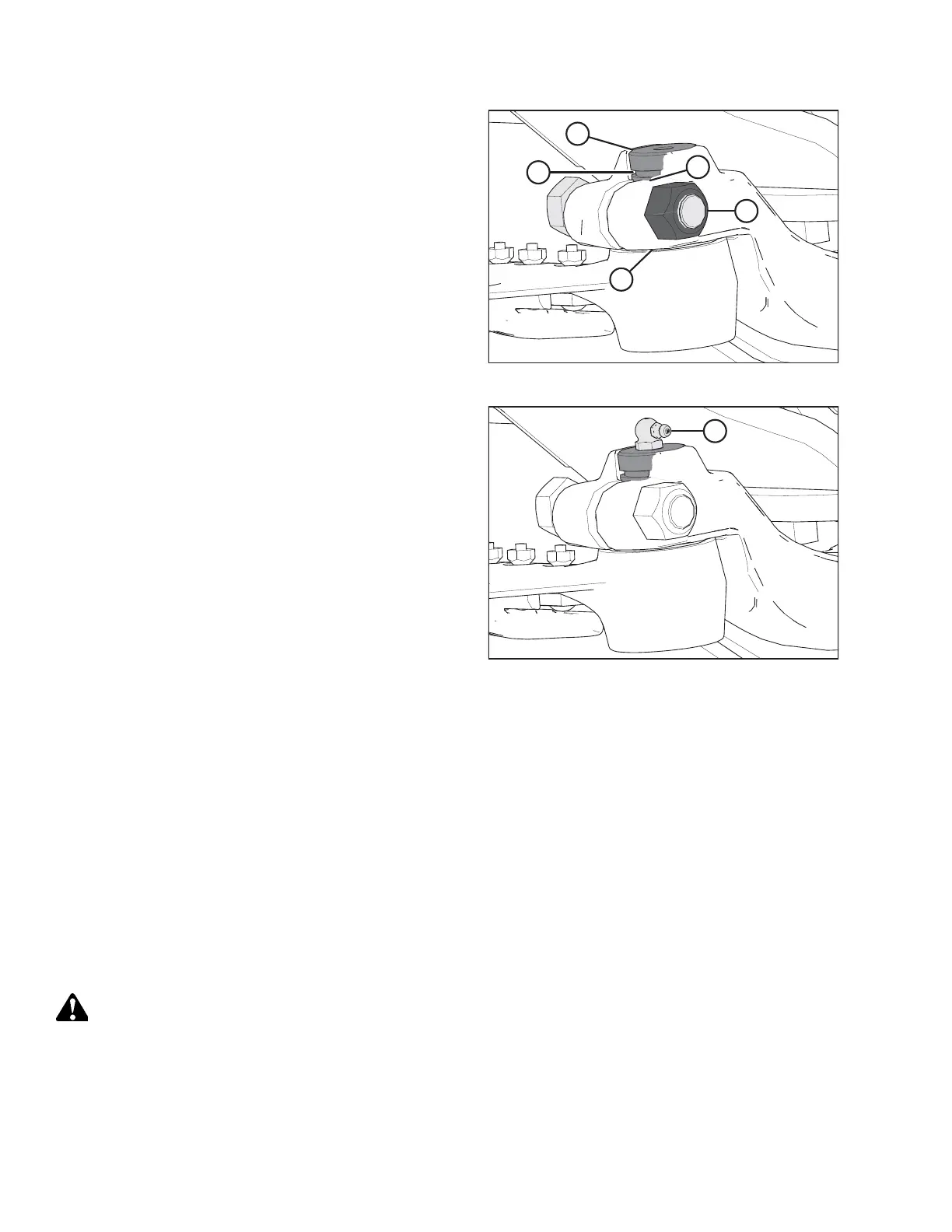

Figure 5.32: Knifehead

9. Install grease fitting (A) into the knifehead pin, and turn the

grease fitting for easy access.

IMPORTANT:

Grease the knifehead just enough to start a slight

downward movement. Overgreasing will lead to knife

misalignment which causes the guards to overheat and the

drive systems to overload.

5.5.6 Spare Knife

A spare knife can be stored in the header frame tube at the left end of the header.

Figure 5.33: Spare Knife

Ensure spare knife (A) is secured in place.

5.5.7 Knife Guards

Perform DAILY inspections to ensure the knife guards are aligned and the knife sections are contacting the shear surfaces

of the knife guards.

Adjusting Knife Guards

Bent knife guards may be able to be straightened with the optional guard straightening tool.

DANGER

To prevent injury or death from the unexpected start-up of the machine, always stop the engine and remove the key

from the ignition before leaving the operator’s seat for any reason.

NOTE:

Use guard straightening tool (MD #140135) available from your MacDon Dealer.

MAINTENANCE AND SERVICING

Loading...

Loading...