Maintenance work on the superstructure

8.7 Main boom

8 - 38 3 302 574 en Maintenance manual

GMK3060

03.11.2017

8.7.2 Lubricating the telescopic sections

Grease, spare

parts, tools

– A grease gun for the grease nipples on the locking pins.

– A grease gun for the grease nipples on the upper telescopic slide faces.

– A brush or roller for the outer, upper and lower telescopic slide faces.

H

Manitowoc Crane Group Germany GmbH recommends pneumatic grease

spray guns for more effective lubrication of the telescopic slide faces:

Prerequisites – The truck crane must be level.

– The hook block must be unreeved.

– The main boom must be completely retracted and lowered into horizontal

position.

–

A rigging mode must have been set up using the telescope positions

required for maintenance as specified in the rigging tables;

à Lifting

capacity table

.

– The RCL code for the current rigging mode must be entered.

H

If at the start you set up a rigging mode under which the telescope positions

47/100/0/0/0 are released in the context of the corresponding rigging table,

this rigging mode allows you to perform the complete maintenance work on

the main boom.

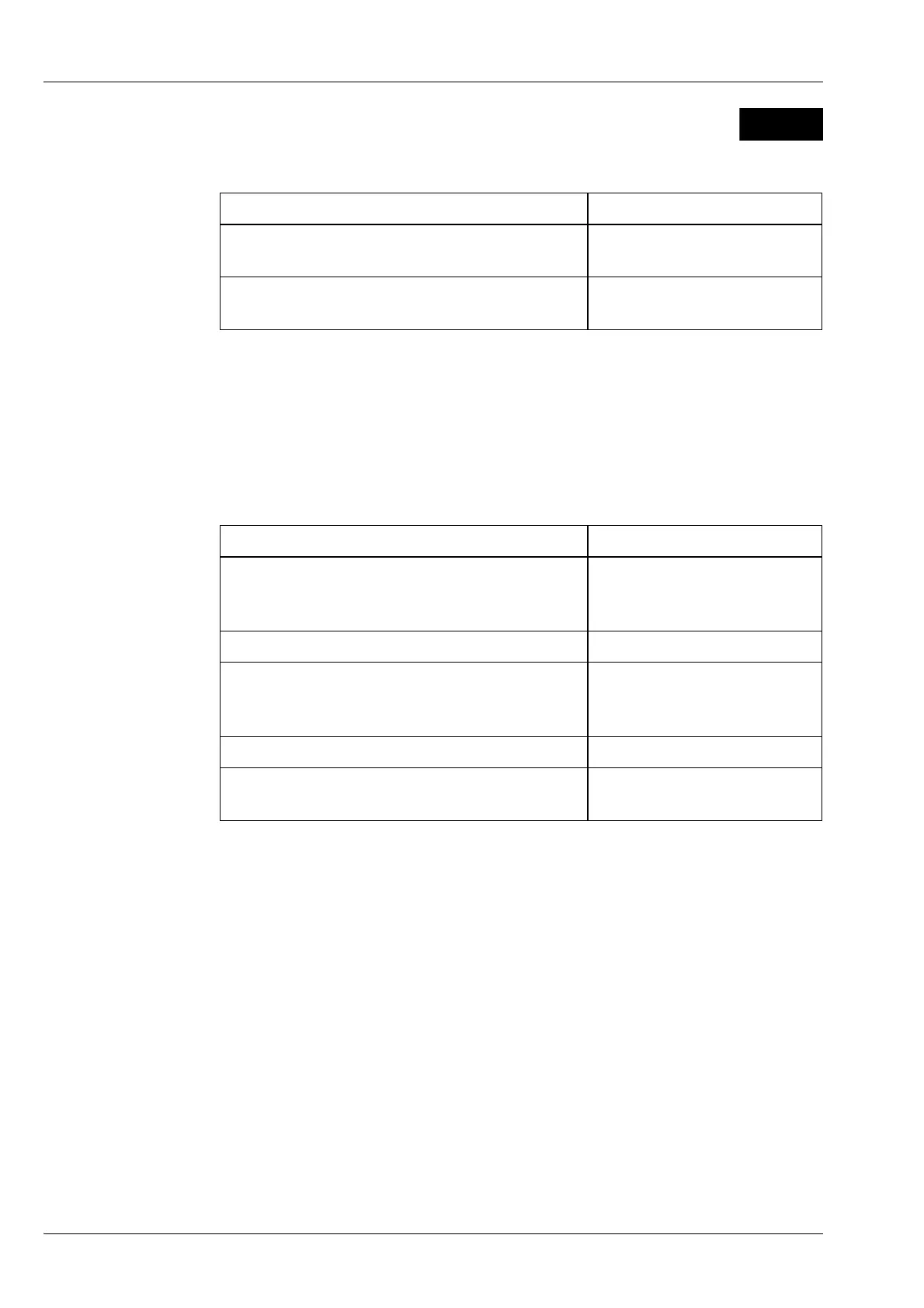

Designation GROVE part no.

Lubricant for the locking pins:

RHUS 2 AF, 1 kg can

03325215

Slide paste for the telescopic slide faces:

PAL1, 25 kg bucket

02314698

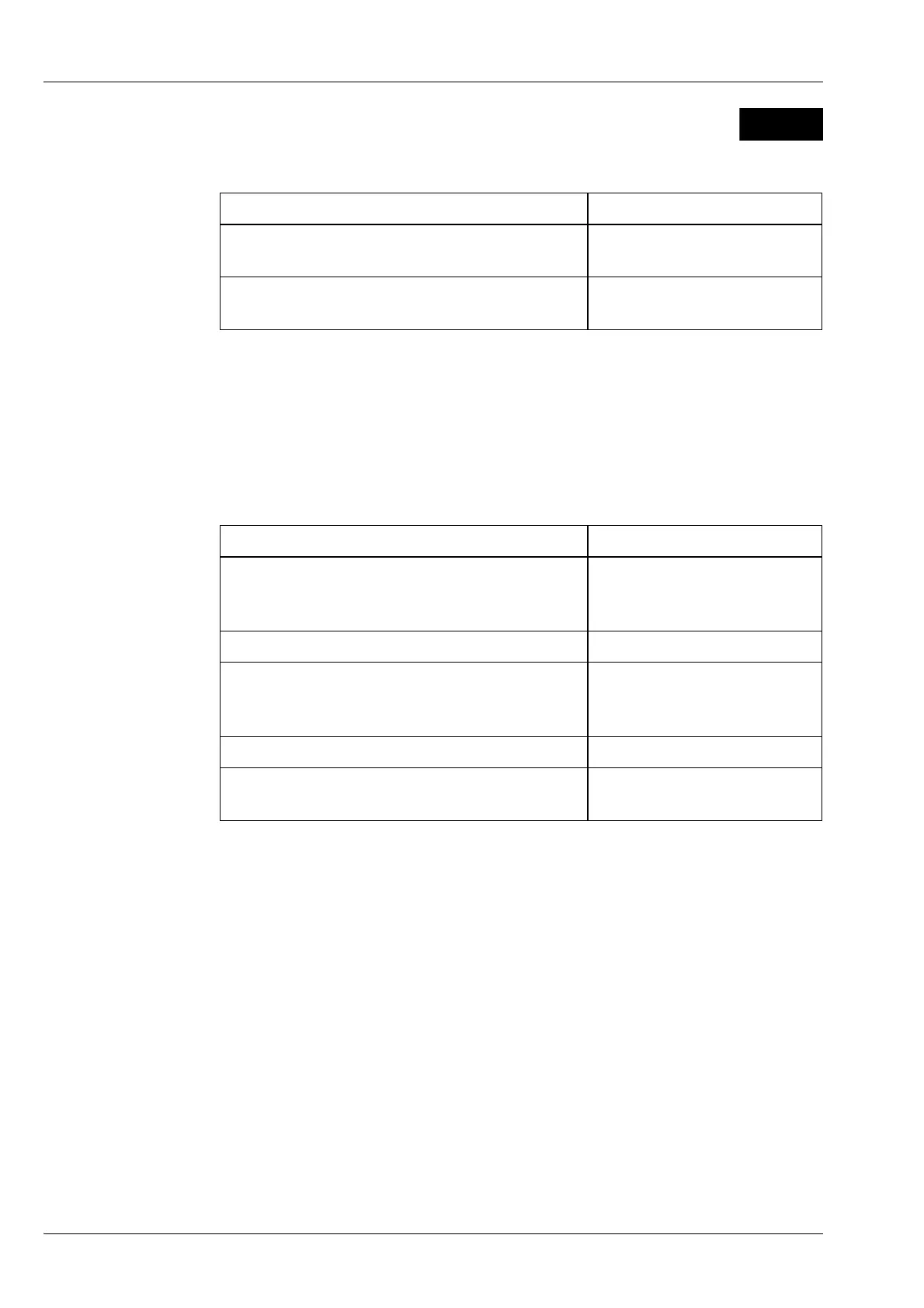

Designation GROVE part no.

Grease spray gun, complete:

Mobile, external compressed air connection

required

03325445

Spray extension, length 2 m, splittable 04159862

Manual grease spray gun for cartridge:

Via the tyre inflator connection on the truck

crane

03329027

25 m hose for manual grease spray gu

n: 03329072

Slide paste for the telescopic slide faces:

PAL1, 400 ml cartridge, refillable

03329071

Loading...

Loading...