Lubricants and consumables

6.1 Lubricants

03.11.2017

Maintenance manual 3 302 574 en 6 - 3

GMK3060

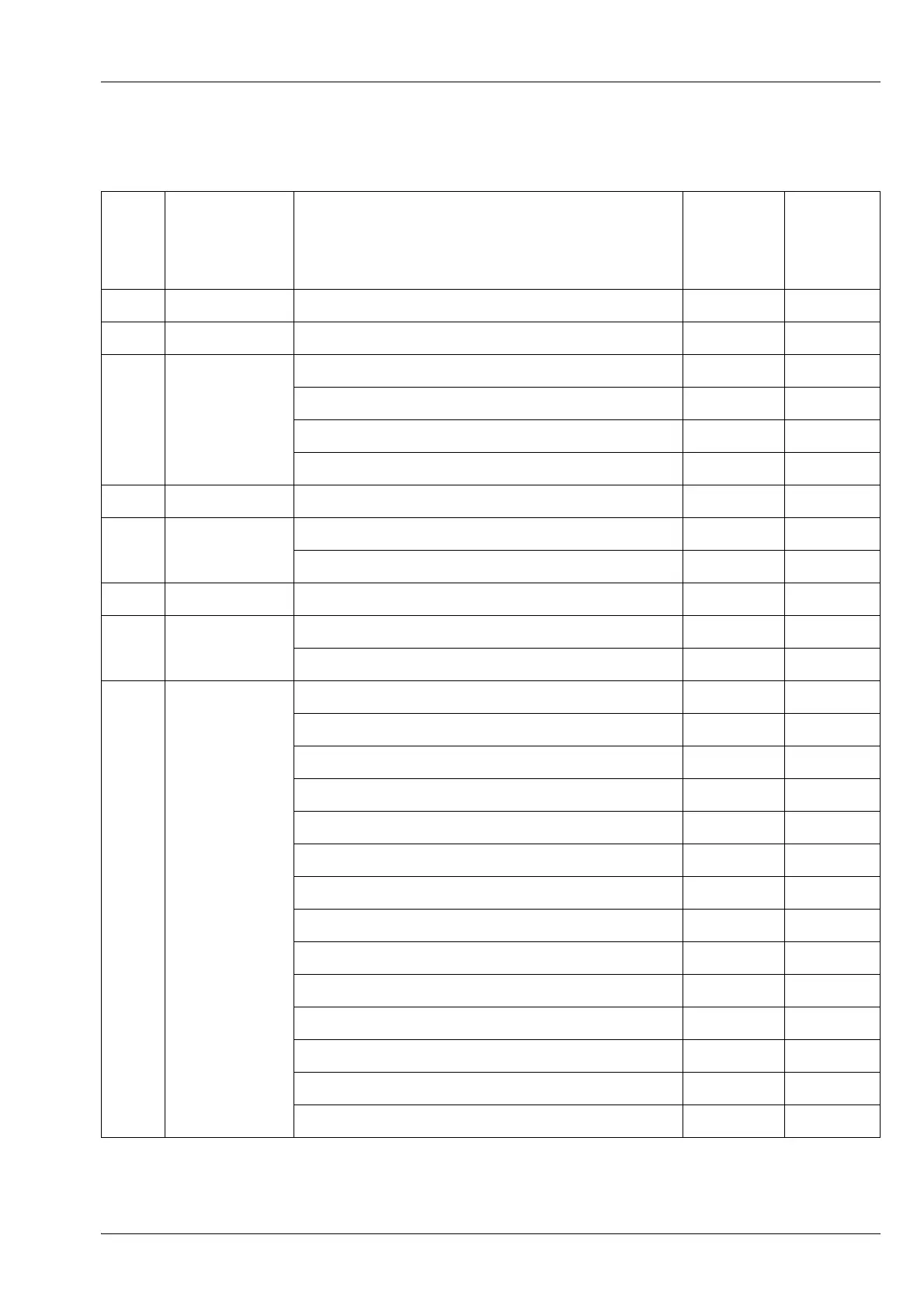

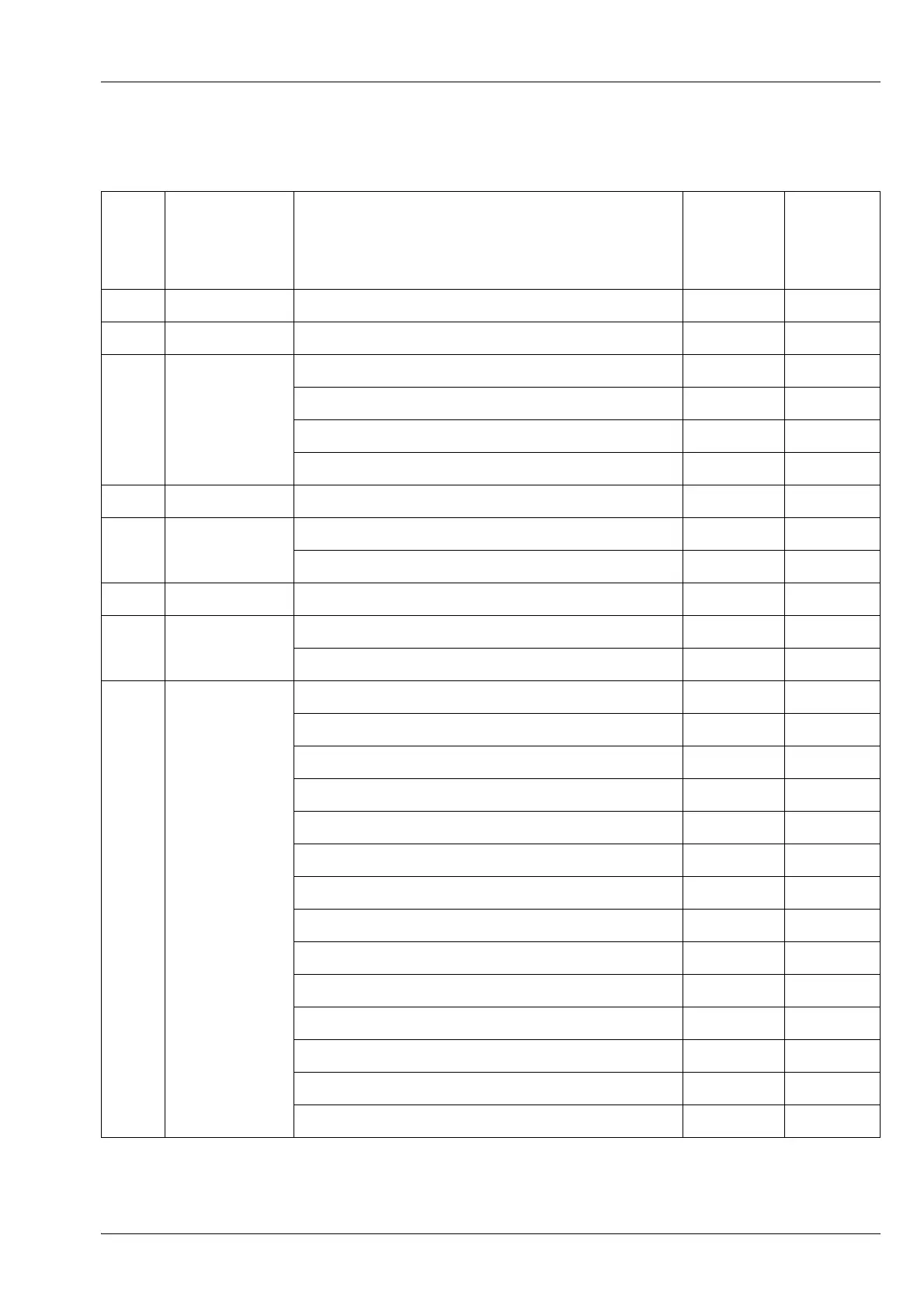

6.1.2 Lubricant applications list

Con-

sec.

no.

Lubricant

type

Usage Fill quan-

tity

in litres

(gal)

Mainte-

nance

interval

1

Engine oil Diesel engine; à p. 7 - 24 26.5 (7.0) M 6

2

Gear oil Manual transmission; à p. 7 - 48 12.5 (3.3) Y 2

3

Gear oil

1st axle line axle centre drive;

à p. 7 - 53 13.0 (3.5) M 12

2nd axle line axle centre drive; à p. 7 - 53 16.2 (4.3) M 12

3rd axle line axle centre drive; à p. 7 - 53 13.0 (3.5) M 12

4 or 6 x final drives; à p. 7 - 56 1.4 (0.4) M 12

4

Gear oil 6 x suspension struts; à p. 7 - 71 1.5 (0.4) M 1

5

Gear oil

2 x hoists;

à p. 8 - 12 3 (0.8) M 12

Slewing gear transmission; à p. 8 - 19 0.9 (0.24) M 12

6

Gear oil Slewing gear brake; à p. 8 - 21 1 (0.26) M 12

7

Hydraulic oil

Hydraulic tank;

à p. 7 - 93 800 (210) M 12

Driver's cab tilting system; à p. 7 - 3 1 (0.26) M 12

8

Lubricating

grease

Carrier central lubrication;

à p. 7 - 101 W

Superstructure central lubrication; à p. 8 - 63 W

Cardan shafts – transverse; à p. 7 - 58 M 1

Cardan shafts – longitudinal; à p. 7 - 59 M 6

Drag link supporting plate; à p. 7 - 76 M 1

Towbar coupling; à p. 7 - 119 M 1

Outrigger beams; à p. 7 - 128 M 1

Auxiliary hoist; à p. 8 - 11 M 6

Turntable lock; à p. 8 - 32 M 12

Slewing angle sensor; à p. 8 - 62 Y 5

Hook blocks; à p. 8 - 65 M 12

Cab door hinges; à p. 7 - 129 M 12

Carrier pins; à p. 7 - 130 M 12

Superstructure pins; à p. 8 - 76 M 12

s

Loading...

Loading...