Maintenance work on the carrier

7.8 Wheels

7 - 64 3 302 574 en Maintenance manual

GMK3060

03.11.2017

7.8.4 Changing the wheels

The wear on tyres varies depending on whether the axle

– is driven/not driven,

– is steered/not steered,

– is braked/not braked,

– and whether it is subject to more or less load.

To achieve even wear, you must swap the wheels to different positions reg-

ularly.

This will have a positive effect on tyre life and performance.

Spare parts

and tools

– Torque wrench for

650 Nm

(480 lbf ft).

Prerequisites – The engine must not be running and must be secured against unauthor-

ised use;

à p. 2 - 3.

Changing

the wheels

• Remove the wheels from the axles.

Only for two-piece aluminium rims

• Have a specialist workshop check the bolts on the two-piece aluminium

rims, using the appropriate special tool.

Depending on the manufacturer, the bolted connection can be recognised

by the bolts on the outer face of the wheel rim. On the inner face of the

wheel rim are nuts whose tightening torque you must have checked in a

specialist workshop;

à Recognising two-piece aluminium rims, p. 7 - 65.

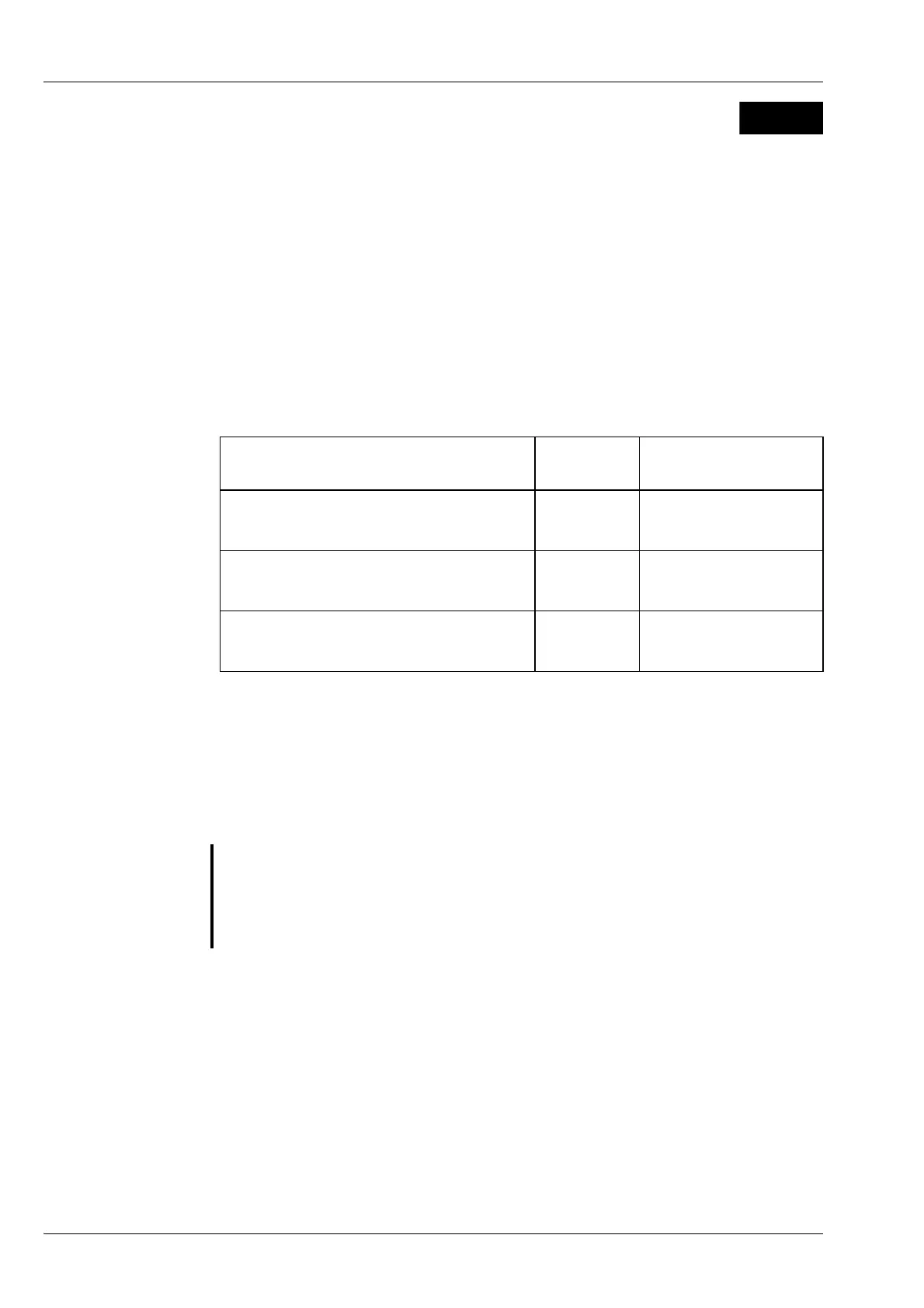

Designation Quantity

per wheel

GROVE part no.

Wheel nut with pressure plate

for steel rims

10 01207756

Wheel nut with pressure plate

for aluminium rims (ALCOA)

10 7659100000

Wheel nut with pressure plate

for aluminium rims (BIMECC)

10

03246867

G

Risk of accidents if the procedure is not carried out correctly!

This section only shows the sequence to be followed when changing

wheels.

When removing/installing the wheels, observe all the safety instructions

and the procedure stated in the operating manual.

Loading...

Loading...