Installation and User Manual

52

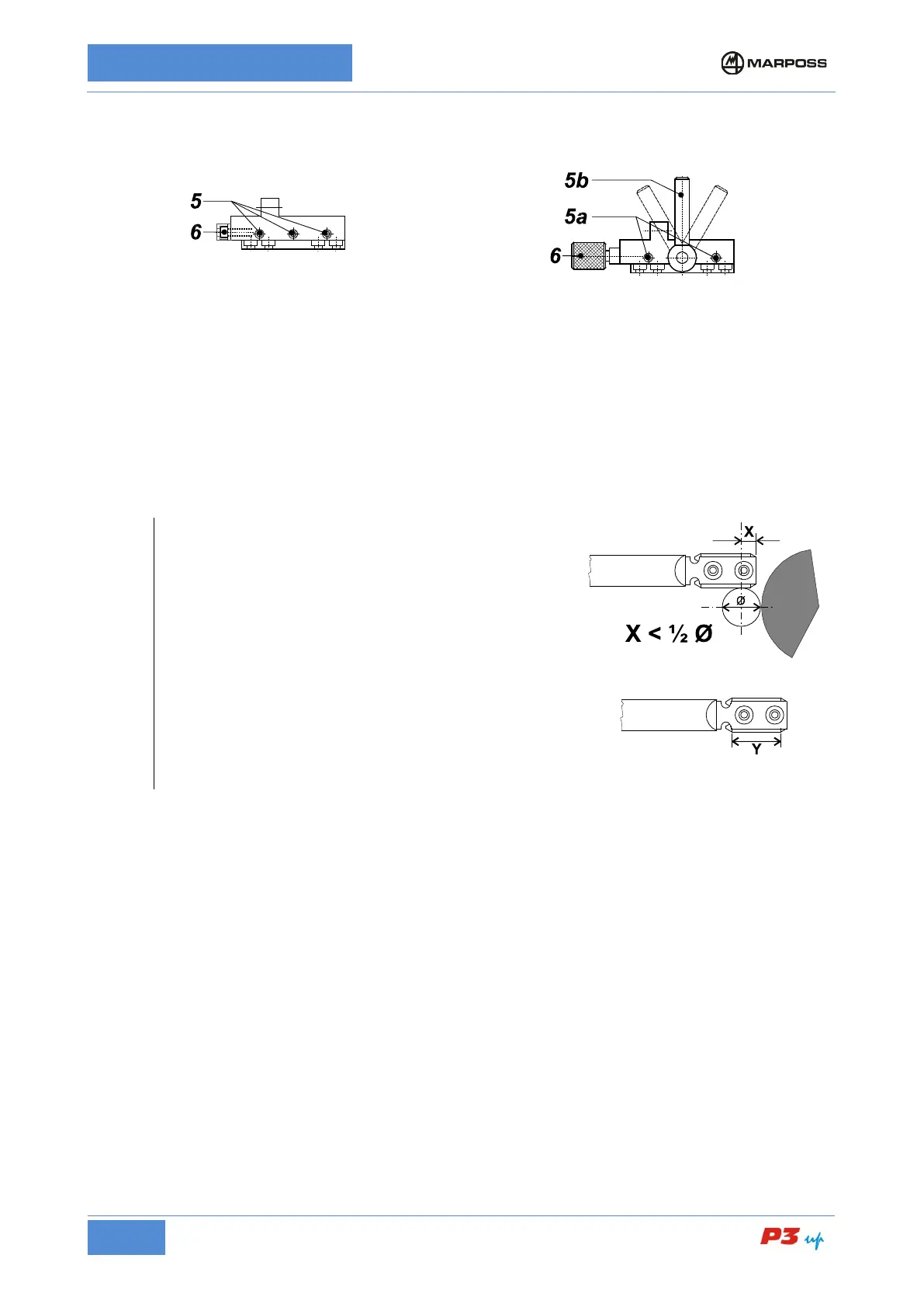

Head support – Slide with

retaining screws

Loosen screws 5 maintaining the friction on them.

Head support – Slide with

locking handle

Release the movement of the head support by

adjusting the handle 5b.

Adjust screws 5a so as to allow frictioned movement of

Rotate the screw/knob 6 moving the measuring head forwards/backwards(*) until it reaches the position

corresponding to the maximum measurement readout (contacts on diameter); refer to the diameter display

on the electronic unit.

Tighten screws 5.

Lock the head support with handle 5b.

Rotate the screw/knob 6 in the opposite direction to release it and avoid tensioning the adjustment system.

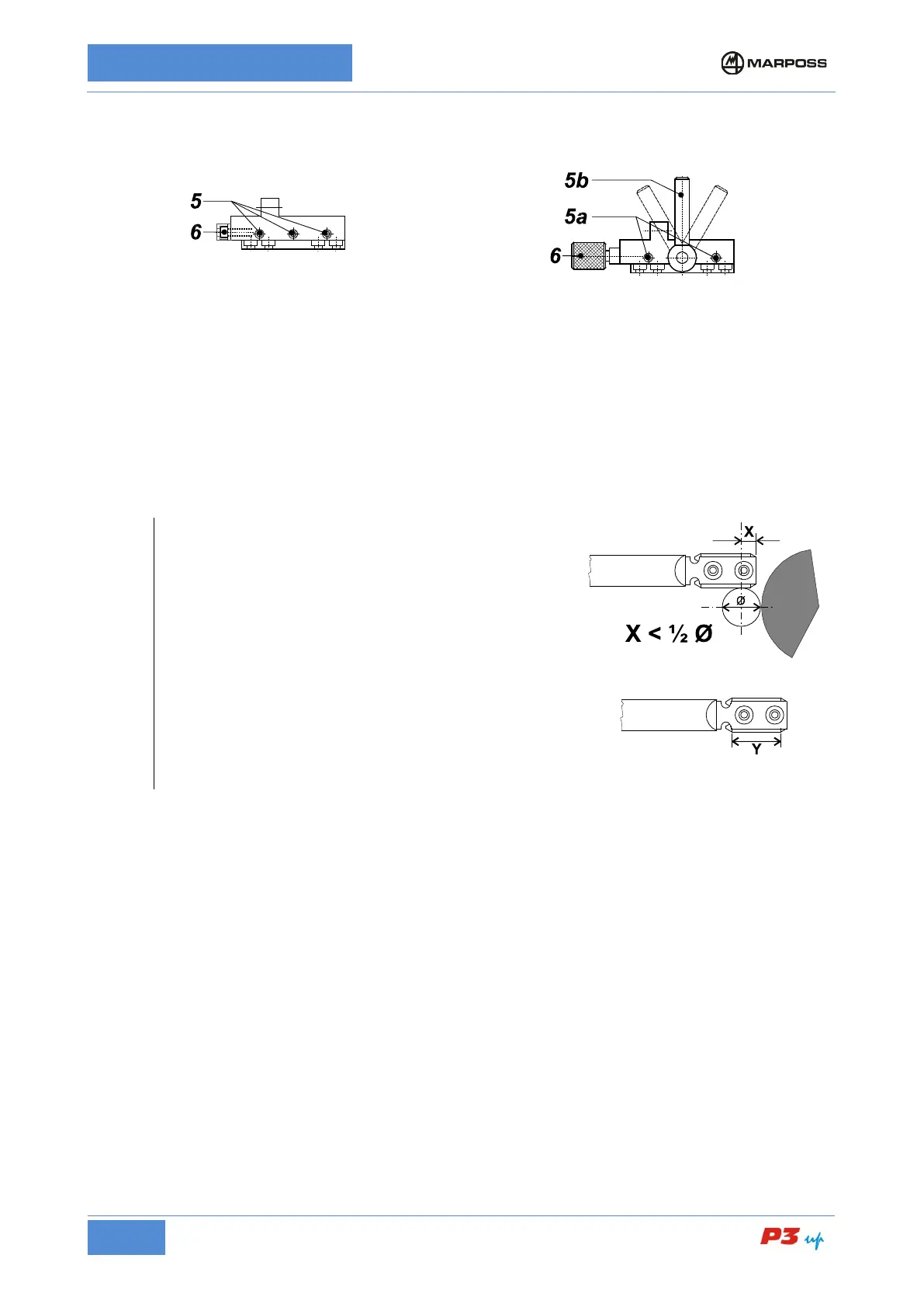

Measurement heads with bar contacts

When positioning the contacts lengthwise on the workpiece

(measuring head back/forth movement) pay attention to

value X.

Value X shall be less than ½ the diameter to be measured

in order to prevent a collision between stylus and wheel.

Measuring grooved parts

When measuring grooved parts with interruptions ≤

the working portion Y of the contact should be greater than

the interruption sector. If there be interruptions with

different lengths, consider the longest one.

Interruptions >10 mm must be considered one at a time.

• Adjusting the Upper Contact

(Refer to the examples in Figure 12: Measurement head with two ball probes, Figure 13: UNIMAR

measurement heads with ball probes, Figure 14: Measurement head with two bar probes, and Figure 15:

UNIMAR measurement heads with bar probes)

1. Loosen screw 1 maintaining the friction on it.

2. Rotate screw 2 (knob or hexagonal head screw) so that the upper contact touches the master workpiece

and the measurement value that appears on the gauge is around zero (± 10 µm).

3. After completing these operations, tighten screw 1 and rotate screw 5.08 cm the opposite direction until

it is released in order to avoid tensioning the adjustment system.

• Adjusting the Lower Contact

(Refer to the examples in Figure 12: Measurement head with two ball probes, Figure 13: UNIMAR

measurement heads with ball probes, Figure 14: Measurement head with two bar probes, and Figure 15:

UNIMAR measurement heads with bar probes)

1. Loosen screw 3 maintaining the friction on it.

2. Rotate screw 4 (knob or hexagonal head screw) so that the lower contact touches the master workpiece

and the measurement value that appears on the gauge is around zero (± 10 µm).

3. After completing these operations, tighten screw 3 and rotate screw 10.16 cm the opposite direction until

it is released in order to avoid tensioning the adjustment system.

Loading...

Loading...