Page 13

Functional Principle, Technical Data

optoNCDT 1700

3.1.2 Direct Reflection

The optoNCDT1700DR consists of an laser-optical

sensor and a signal conditioning electronics. The

sensor uses the principle of optical triangulation, i.e.

a visible, modulated point of light is projected onto

the target surface. The direct element of the reflec-

tion of the light spot is imaged by a receiver optical

element onto a high-sensitivity resolution element

(CCD), in dependency on distance. From the output

signal of the CCD element a digital signal processor

(DSP) in the sensor calculates the distance between

the light spot on the object being measured and the

sensor. The distance is linearized and then issued

via an analog or digital interface.

On shining or mirroring surfaces the direct element

of the reflection of the laser spot is greater and cov-

ers therefore the diffuse part. Suppression of the

2

nd

reflection from the glass rear side in the sen-

sor is possible for measurements on glass panels.

Sensors for direct reflection (ILD1700-2DR, ILD1700-

10DR and ILD1700-20DR) are calibrated in tilted

position. Therefore the can not be used for diffuse

reflection.

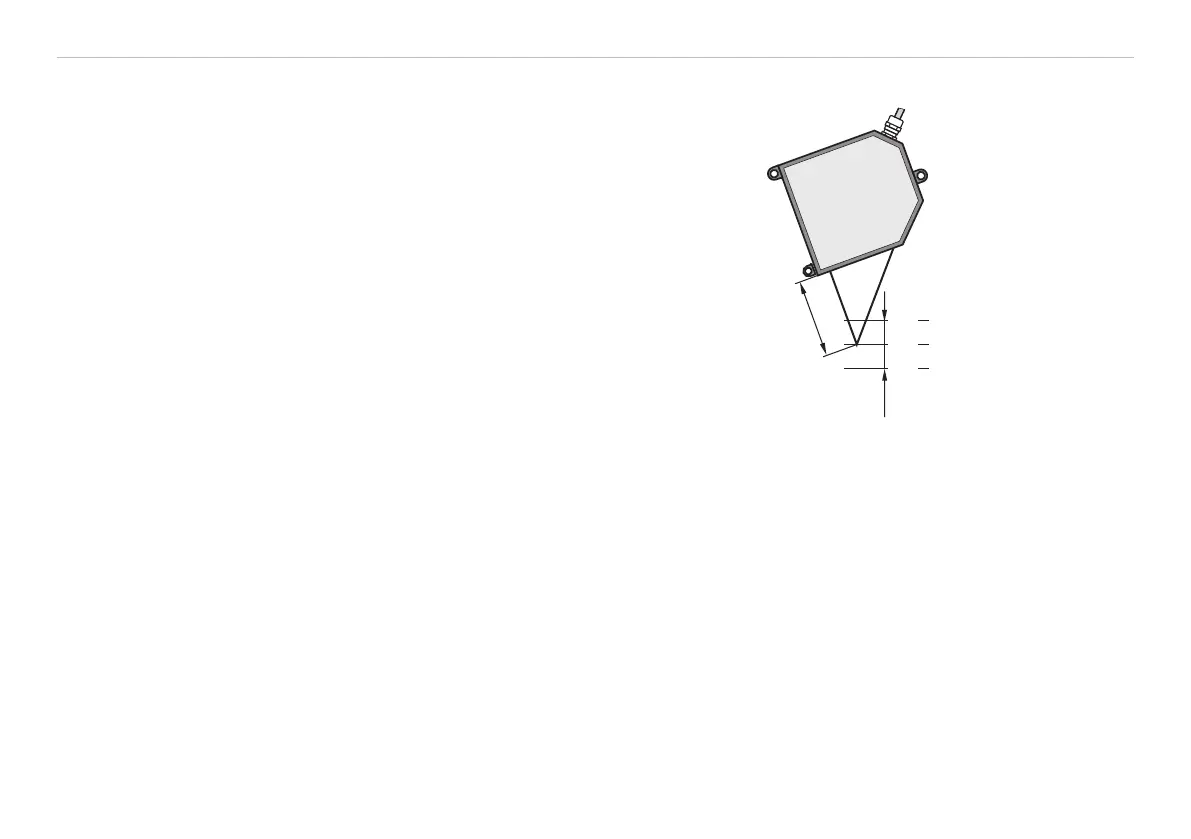

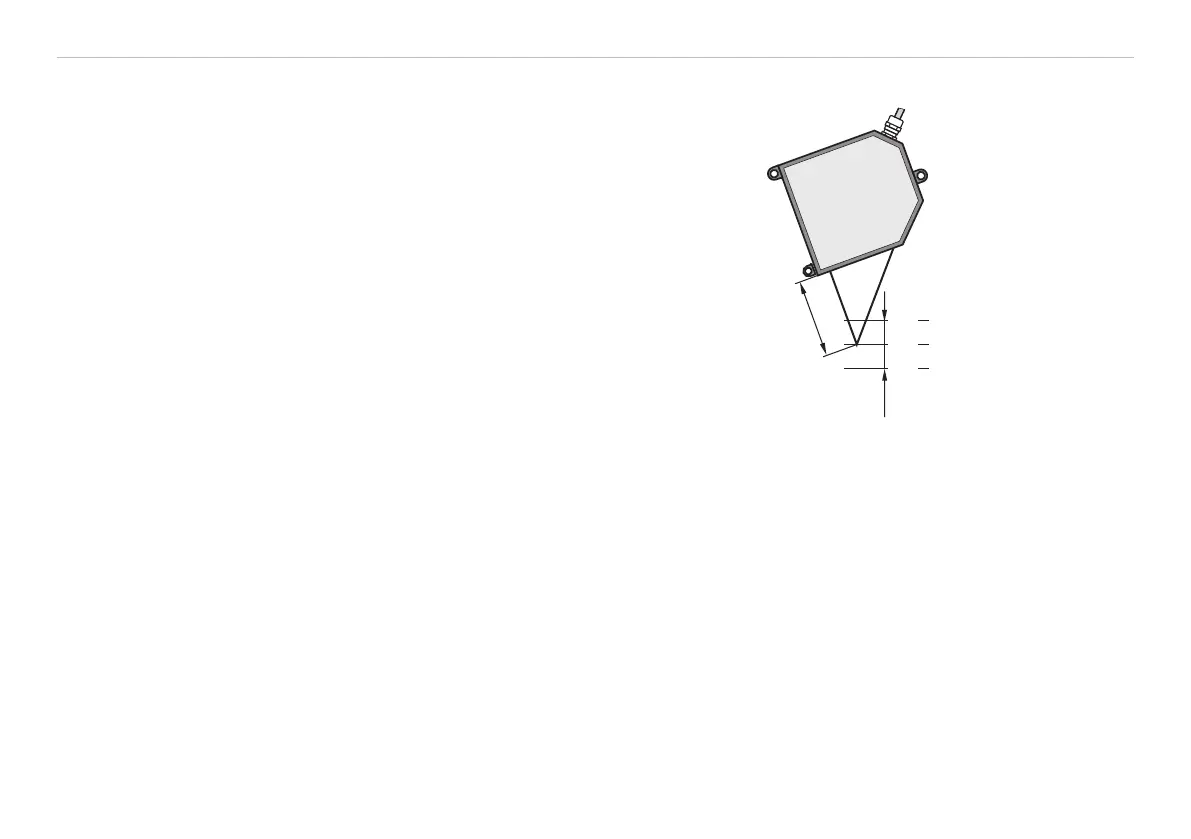

Sensor

ILD1700DR

Analog output

0 VDC 4 mA

5 VDC (MMR) 12 mA

10 VDC (EMR) 20 mA

Measuring range

Midrange

Fig. 3 Definiton of terms, output signal

3.2 Real Time Control

The signal from the CCD element is used to determine the intensity of the diffuse reflection. This enables the

sensor to compensate for fluctuations in brightness on the object being measured. What is more, it does so

in a range from almost total absorption to almost total reflection.

SMR = Start of

measuring range

MMR = Midrange

EMR = End of

measuring range

Loading...

Loading...