Page 47

Operation

optoNCDT 1700

6.9 Frequency and Output Rate

The measurement frequency defines the number of measurements performed by the sensor per second. The

measurement frequency may be 2.5 kHz, 1.25 kHz, 625 Hz or 312.5 Hz. Details of how to change the

measurement frequency, see Chap. 6.5.

The output rate gives the actual number of measurement values at the sensor output per second. The

maximum output rate can never exceed the measurement frequency.

Output Maximum output rate

The sensor continues to measure internally but holds

back the output until the last measurement value has

been issued in full. The next measurement value is

the last valid value, with other values between being

lost.

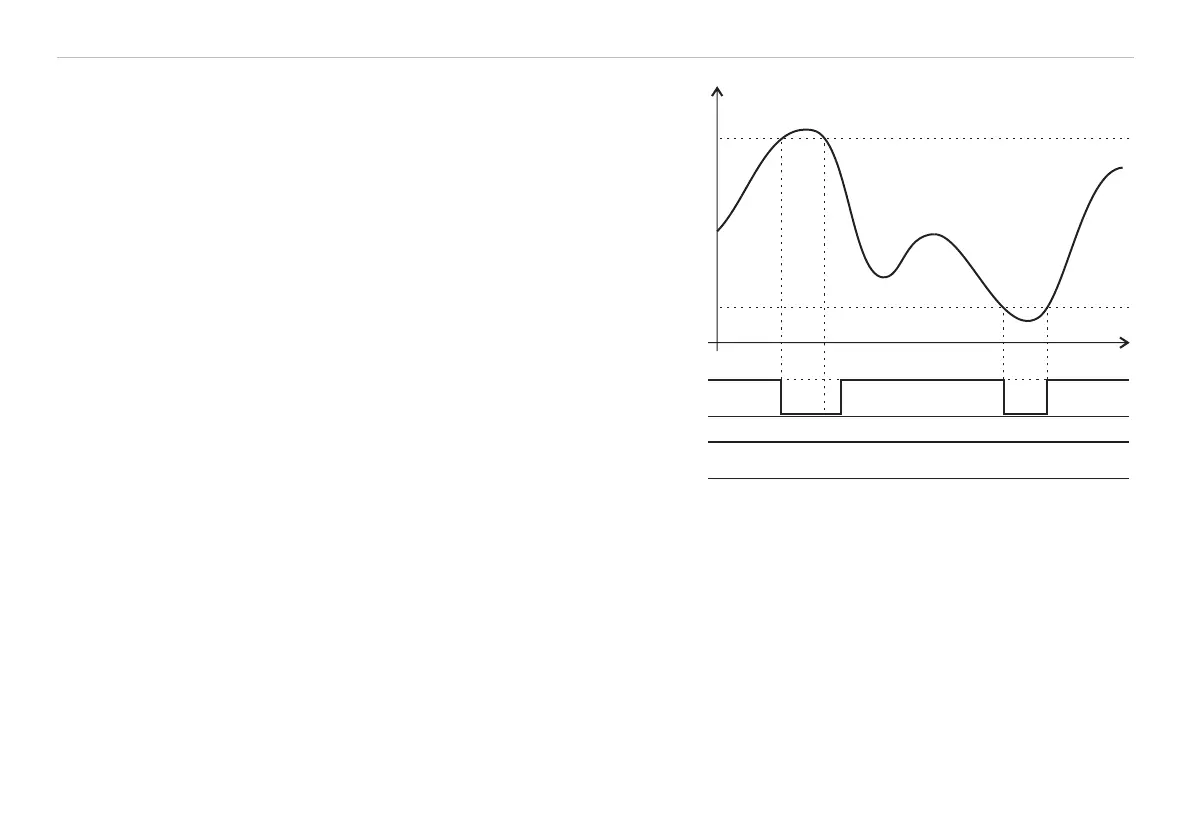

Fig. 26 Output rates for the output types

Current Measurement frequency

Voltage Measurement frequency

RS422

Output rate Measurement frequency;

Dependent on the transmission rate

(baud rate) and data format (ASCII-Code).

Calculation of the output rate using the RS422 serial interface:

Output rate = Measuring frequency n

Abbreviations used:

n = Partial factor

int = Integral part of ( )

b = Byte/measurement value

(binary format b=2, ASCII b=6))

MR = Measurement frequency [Hz]

BR = Baud rate [Baud]

n = int (b * 11 * MR / BR) + 1

The values are summarized, see Chap. A 3.

Example:

Measurement frequency = 1250 Hz, ASCII-Format (b=6), Baud rate = 19200 Baud

--> n = int (4.3) + 1 = 5

--> Output rate = 1.25 kHz / 5 = 250 Hz.

IMPORTANT!

Synchronized

sensors must always

be set to the same

measurement

frequency.

Please, see Chap. A 3.

Recommendations:

- Use a high measure-

ment frequency for light

colored and matt ob-

jects to be measured.

- Use a low measure-

ment frequency for

dark or shiny objects to

be measured (e.g.

surfaces covered in

black lacquer), for bet-

ter measurement

results.

6.10 Operation Mode

6.10.1 Error Mode

(Error Control)

In error mode, the switching output 1 is used as

an error output. The switching output 2 remains

inactive. The error mode can be programmed

using both the keypad and the programming

interface.

The error output is activated (conducting to

GND) when:

- the object to be measured is outside the

measurement range, see Fig. 27,

- there is no object to be measured present, or

- if the object to be measured is unsuitable (too

dark, polished metal, insufficiently reflective).

Transparent objects can be penetrated by the

light of the laser and the laser spot unacceptably

enlarged, resulting in unreliable measurements.

This will also trigger the error output.

6.10.2 Switch Mode

(Limit Control)

In switch mode, both switching outputs

are used as limit switches, see Fig. 28.

The individual limits can be programmed using

the digital programming interface, see Chap.

8.5.7, see Chap. 8.5.8.

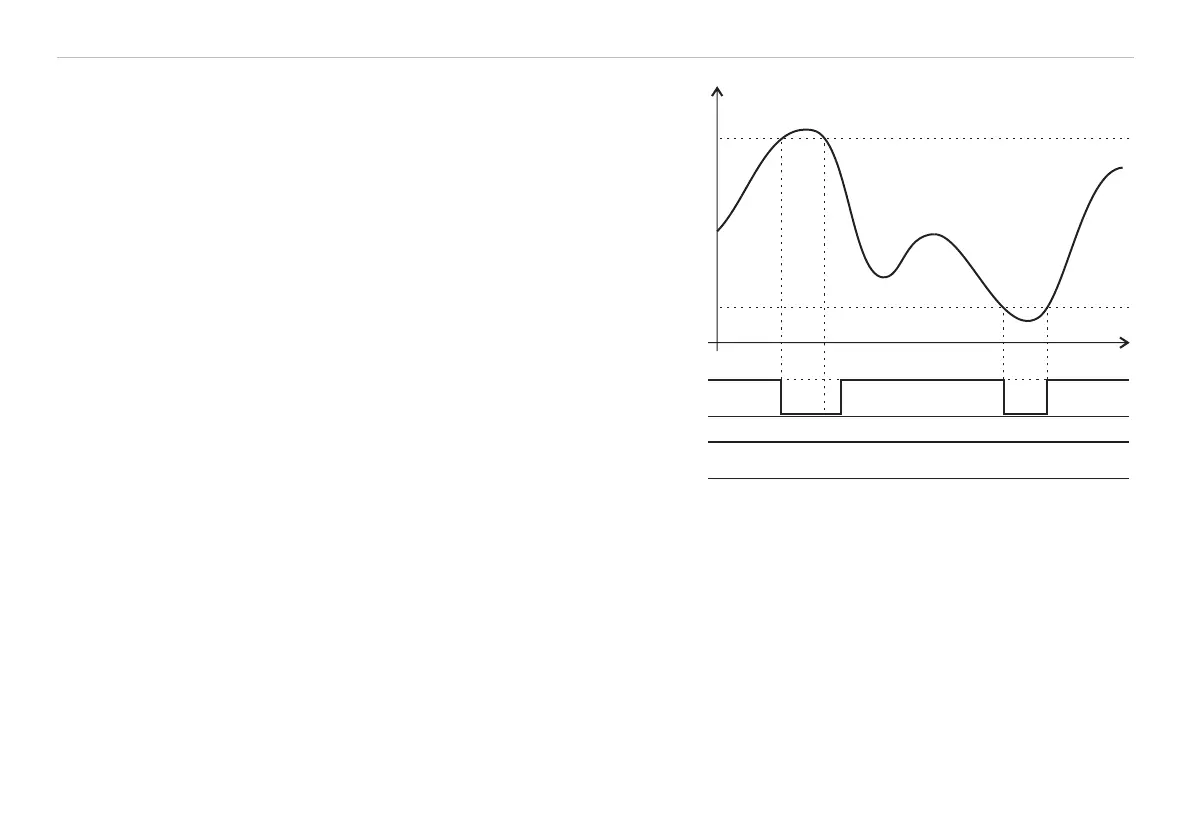

Measured value

EMR

+

GND

+

GND

Switching output 1

Switching output 2

SMR

Time

Fig. 27 Signal sequence for the switching outputs in the

operation mode „Sync error“ and „Trigger error“

Error mode: Setting mid-point only, no limit control

Switch mode: Mastering only, limit control

Loading...

Loading...