Page 94

Instruction for Operating

optoNCDT 1700

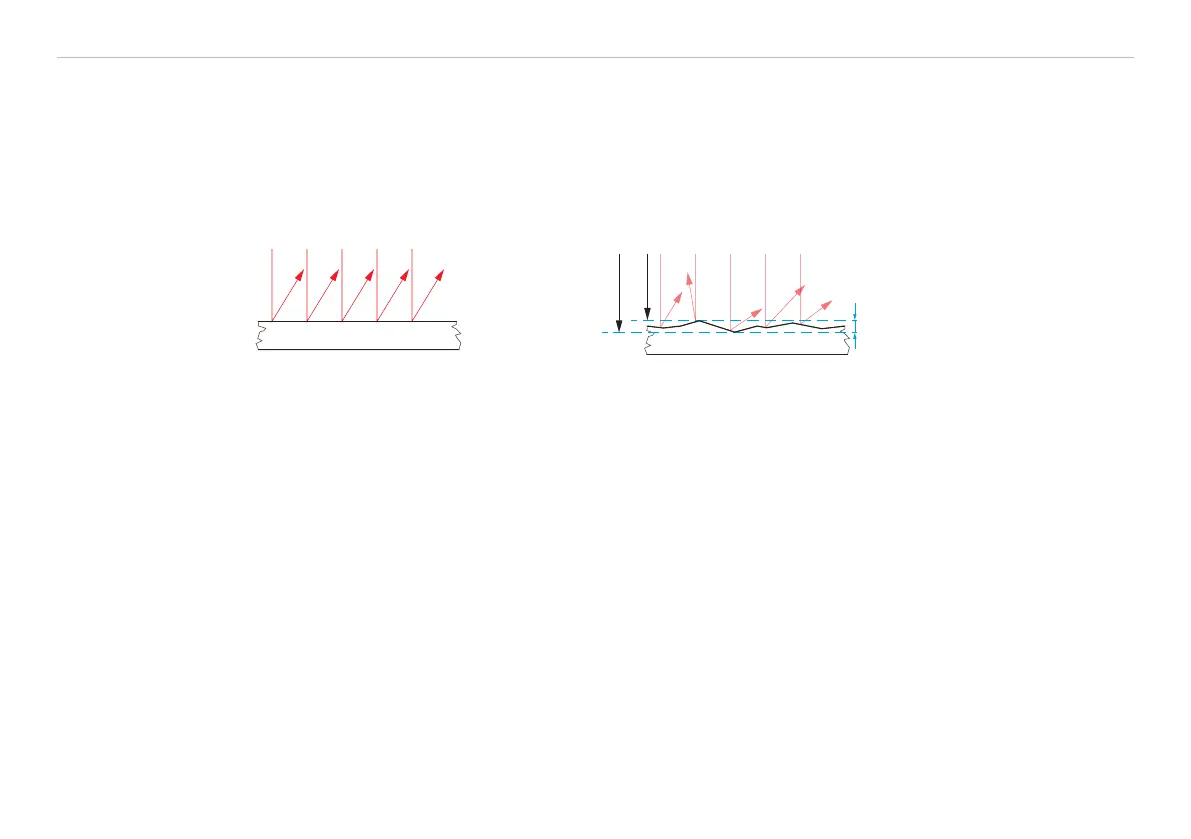

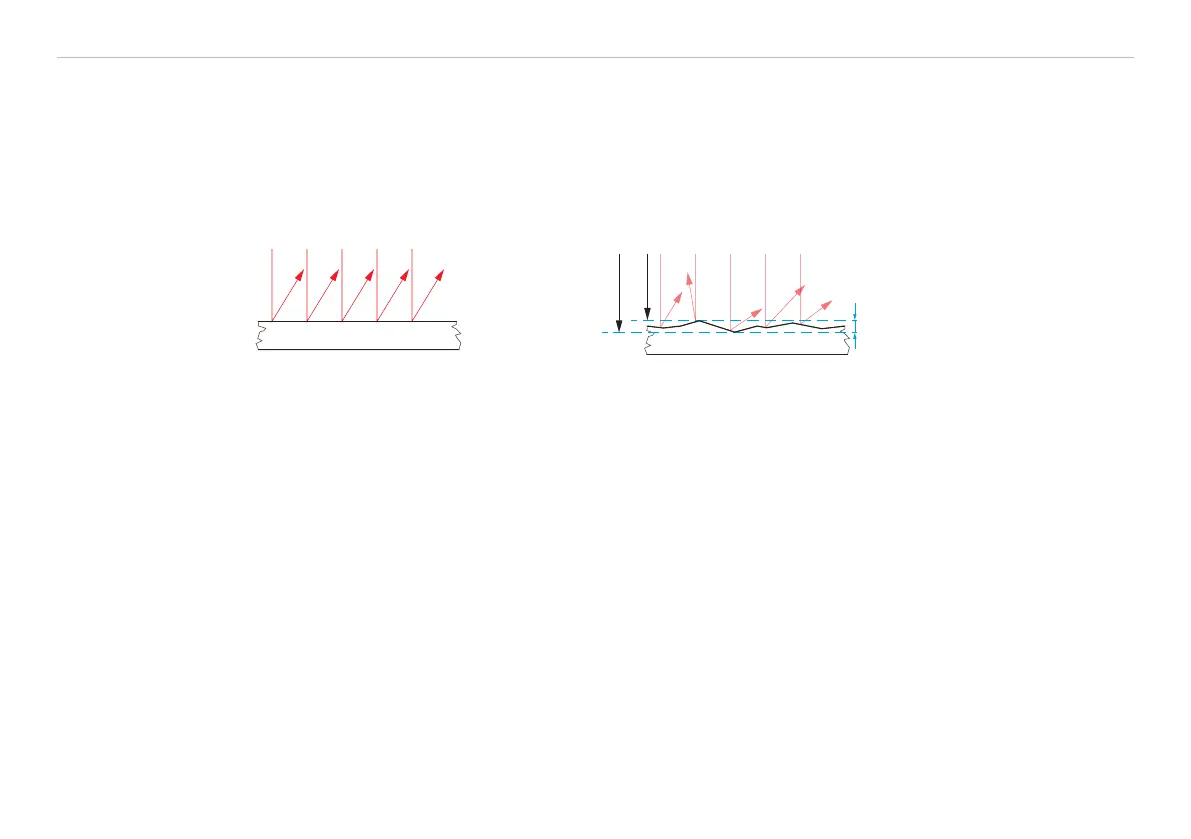

9.2.6 Surface Roughness

Laser-optical sensors detect the surface using an extremely small laser spot. They also track slight surface

unevenness. In contrast, a tactile, mechanical measurement, e.g. using a caliper, detects a much larger area

of the measurement object. In case of traversing measurements, surface roughnesses of 5 μm and more lead

to an apparent distance change.

Suitable parameters for the averaging number may improve the comparability of optical and mechanical

measurements.

h > 5 µm

Max.

Min.

Ceramic reference surface Structured surface

Recommendation for parameter choice:

- The averaging number should be selected in such a way that a surface area the size of which is compa-

rable to those with mechanical measurements is averaged.

Loading...

Loading...