Page 19

Functional Principle, Technical Data

optoNCDT 1700

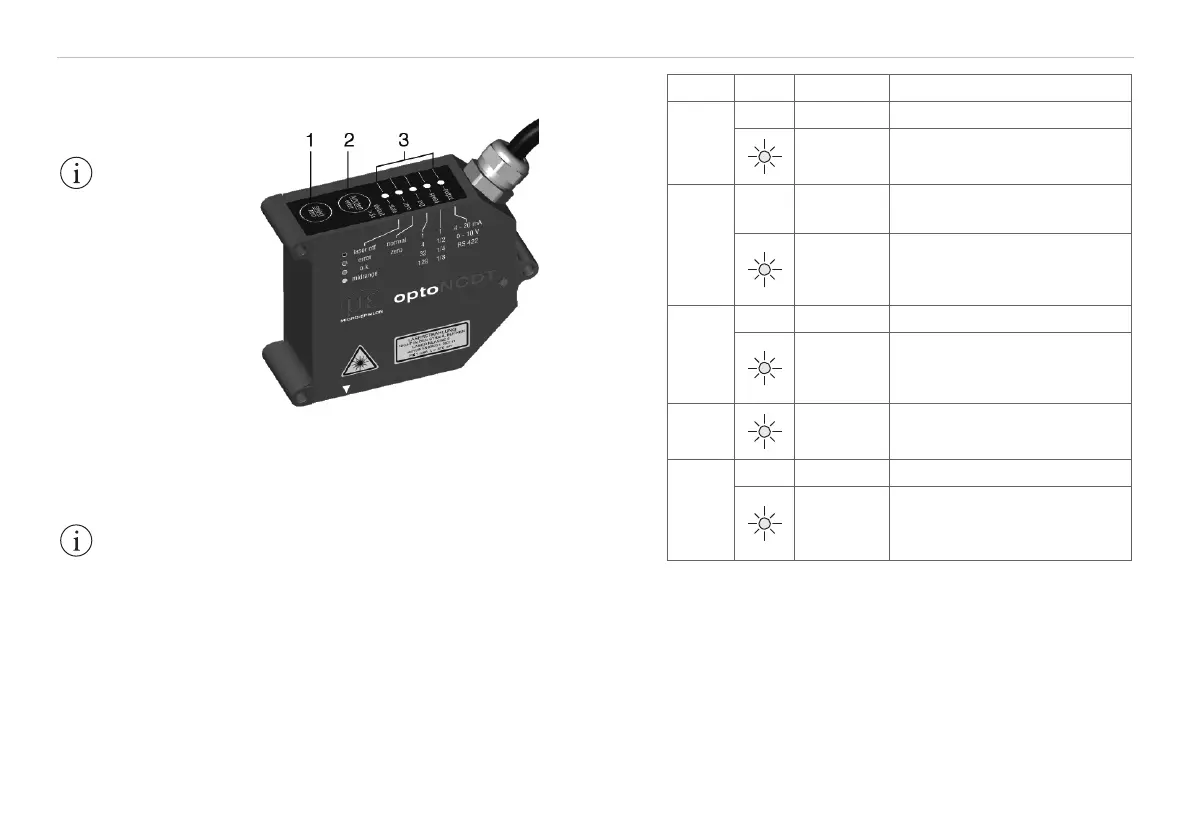

3.5 Control and Indicator Elements

Fig. 4 Keys and LED‘s on the sensor

(1) select/zero key Measurement mode:

Sets analog output to

„Master“ or „Mid-point“, see Chap. 6.7, see

Chap. 6.8.

Setup mode: For changing the sensor

parameters, see Chap. 6.5.

(2) function/enter key

For switching between measurement mode

and setup mode.

(3) LEDs, see Fig. 5.

IMPORTANT!

Keys can be locked

via the serial interface,

see Chap. 8.5.16.

For the meanings of

the LEDs in setup

mode, see Chap. 6.3.

IMPORTANT!

If the function/

enter key is pressed

more than 5 sec, all

para-meters are over-

written by the factory

settings.

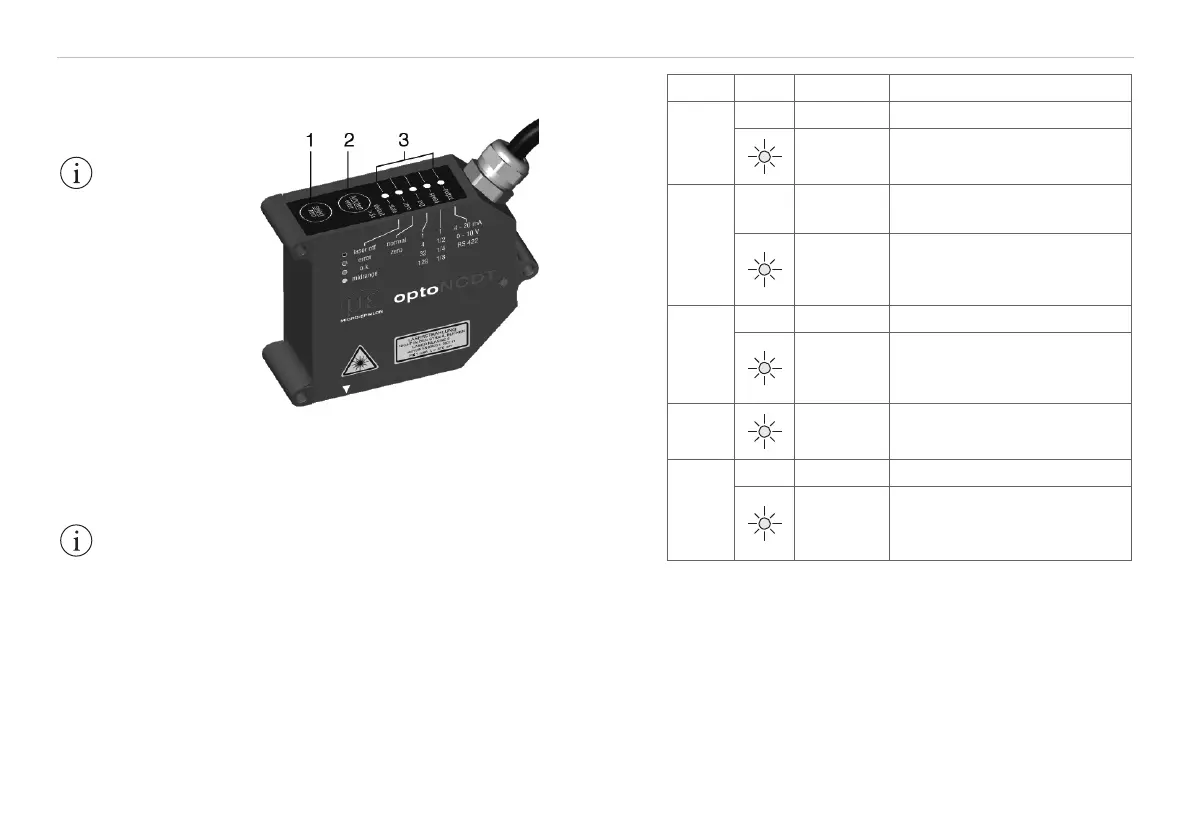

LED Color Meaning

output

o Current (4 ... 20 mA)

red

green

Voltage (0 ... 10 V)

Serial (RS422)

speed

o

Measurement frequency

1 = 2.5 kHz

red

green yel-

low

1/2 = 1.25 kHz

1/4 = 625 Hz

1/8 = 312.5 Hz

avg

o Average: 1 (Median: 3)

red

green yel-

low

4 (5)

32 (7)

128 (9)

zero

red

flashing

Mid-point set / mastered

Slave not synchronized

state

o Laser off

red

green yel-

low

Error

O.K.

MMR (midrange)

Fig. 5 Meanings of the LEDs in measurement mode

Note: In measurement mode (factory setting) only the

LED „state“ lights up, subject to the current position of

the object to be measured.

Loading...

Loading...