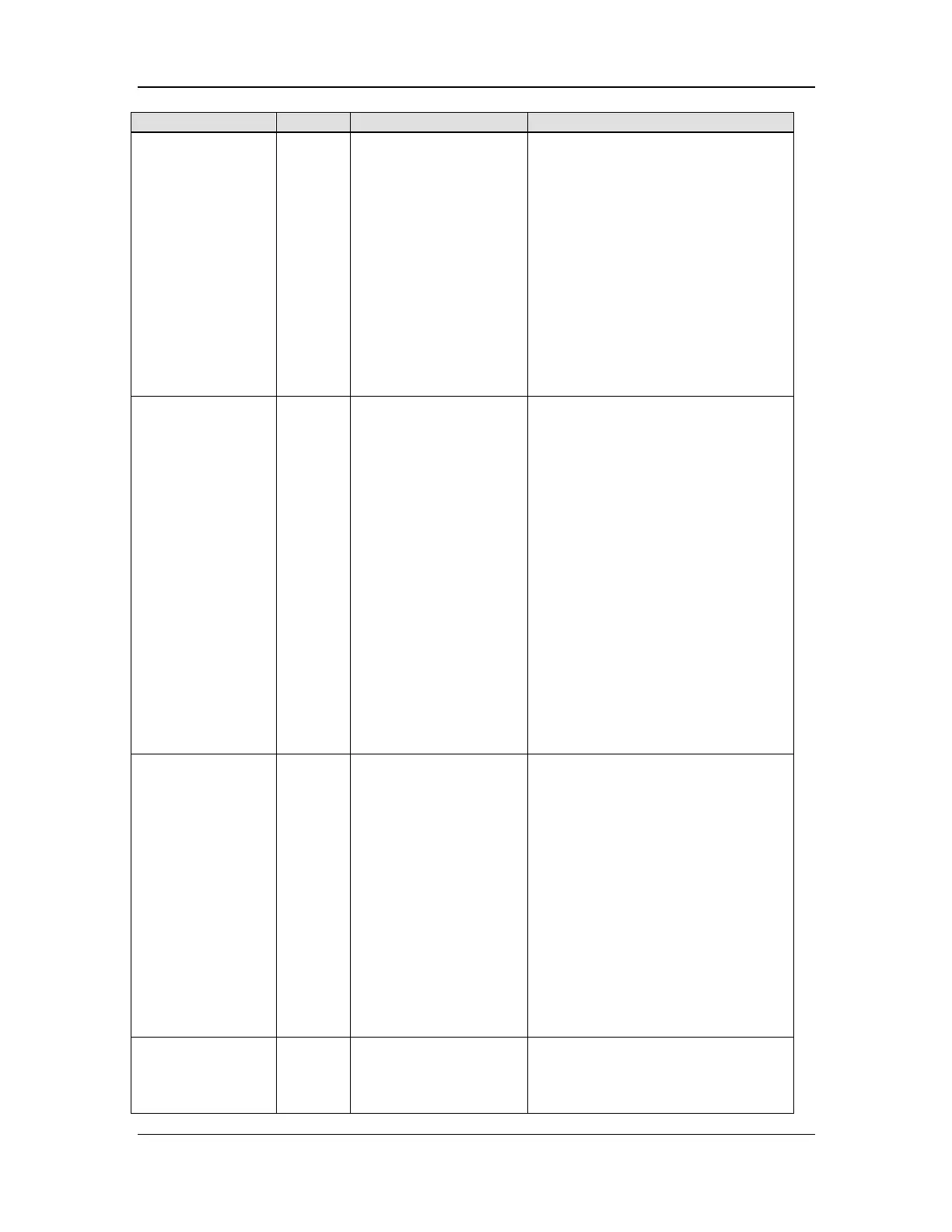

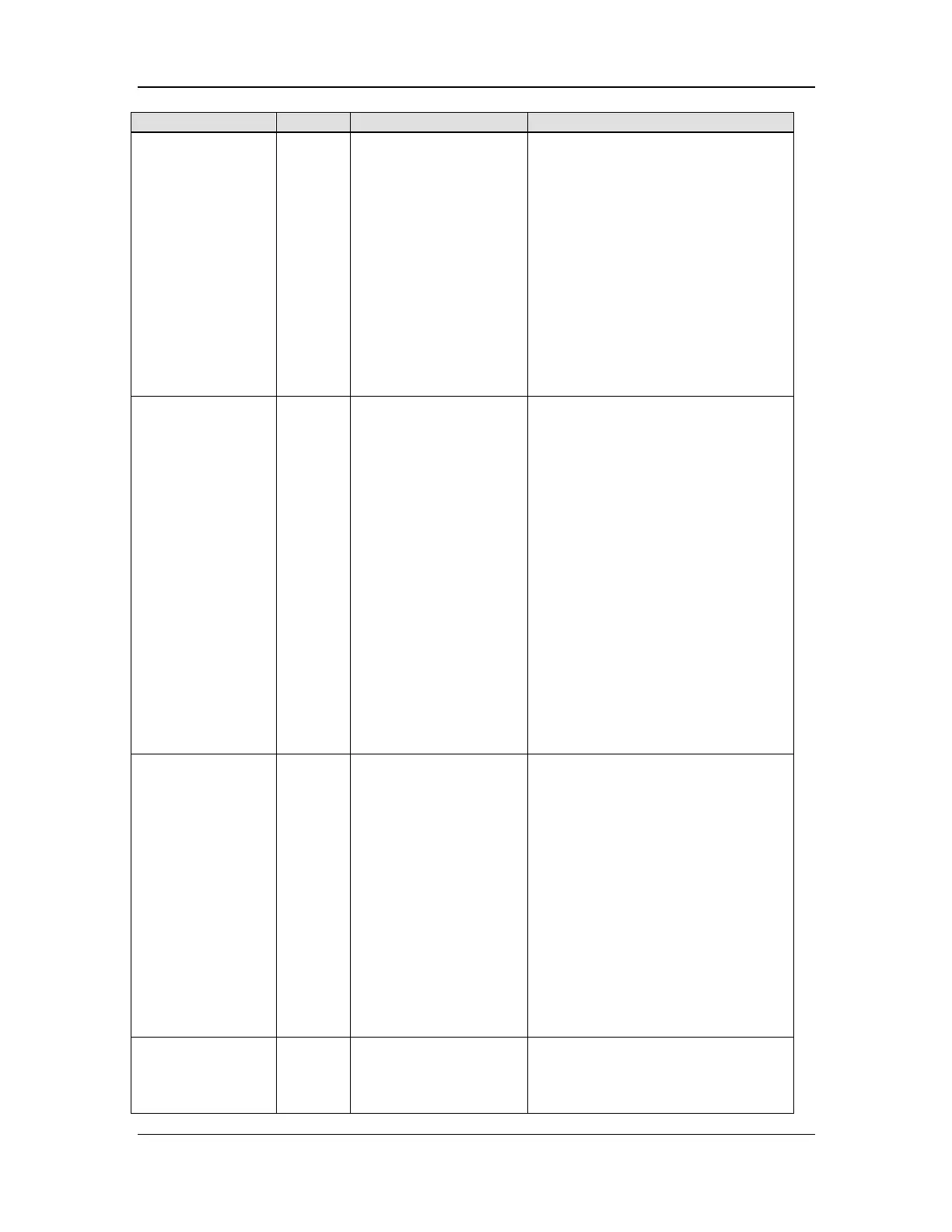

7-16

O2 Branch Flow

Not Achieved

Low

The O2 flow exceeds

the target flow by 10%

or 0.2 L/min, whichever

is larger.

1. Check whether O2 is supplied

normally. The gas supply pressure on

the O2 pipeline should be within the

range of 280- 600kPa (40-87PSI),

and the cylinder pressure should be

within the range of 6.9-20.0MPa

(1000-2900PSI).

2. Check whether the sensor or valve

is faulty by referring to 7.6.5.1.

3. If the sensor is faulty, replace the

flow sensor (refer to 11.3.1).

4. If the valve is faulty, replace the

electronic flowmeter (refer to

Balance Gas

Branch Flow Not

Achieved

Low

The balance gas flow

exceeds the target flow

by 20% or 0.4 L/min,

whichever is larger.

1. Check whether the balance gas is

supplied normally. The gas supply

pressure on the AIR pipeline should

be within the range of 280- 600kPa

(40-87PSI), and the cylinder pressure

should be within the range of

6.9-20.0MPa (1000-2900PSI). The

gas supply pressure on the AIR

pipeline should be within the range of

280- 600kPa (40-87PSI), and the

cylinder pressure should be within the

range of 4.2-6.0MPa(600-870PSI).

2. Check whether the sensor or valve

is faulty by referring to 7.6.5.1.

3. If the sensor is faulty, replace the

flow sensor (refer to 11.3.1).

4. If the valve is faulty, replace the

electronic flowmeter (refer to

Flowmeter Comm

Stop

Med

The CPU board fails to

communicate with the

electronic flowmeter

board for 10s, or

the EFCS CPU fails to

communicate with the

EFCS-PM or VCM for

10s.

2. If the status screen has a

communication stop alarm, or

encounters the black or blank screen

error, rectify the fault of the status

screen first (refer to 7.2.1).

3. If the problem persists, open the

service door (refer to 8.1.1), and

reconnect the cable between the

backplane and the flowmeter

assembly. (For the cable position,

refer to 8.12.)

4. If the problem persists, replace the

electronic flowmeter board (refer to

Self Test Time Out

Total Flow Sensor

Med

EFCS-PM fail to

communicate with the

2. If the problem persists, reconnect

the cable of the flow sensor (refer to

Loading...

Loading...