6-46

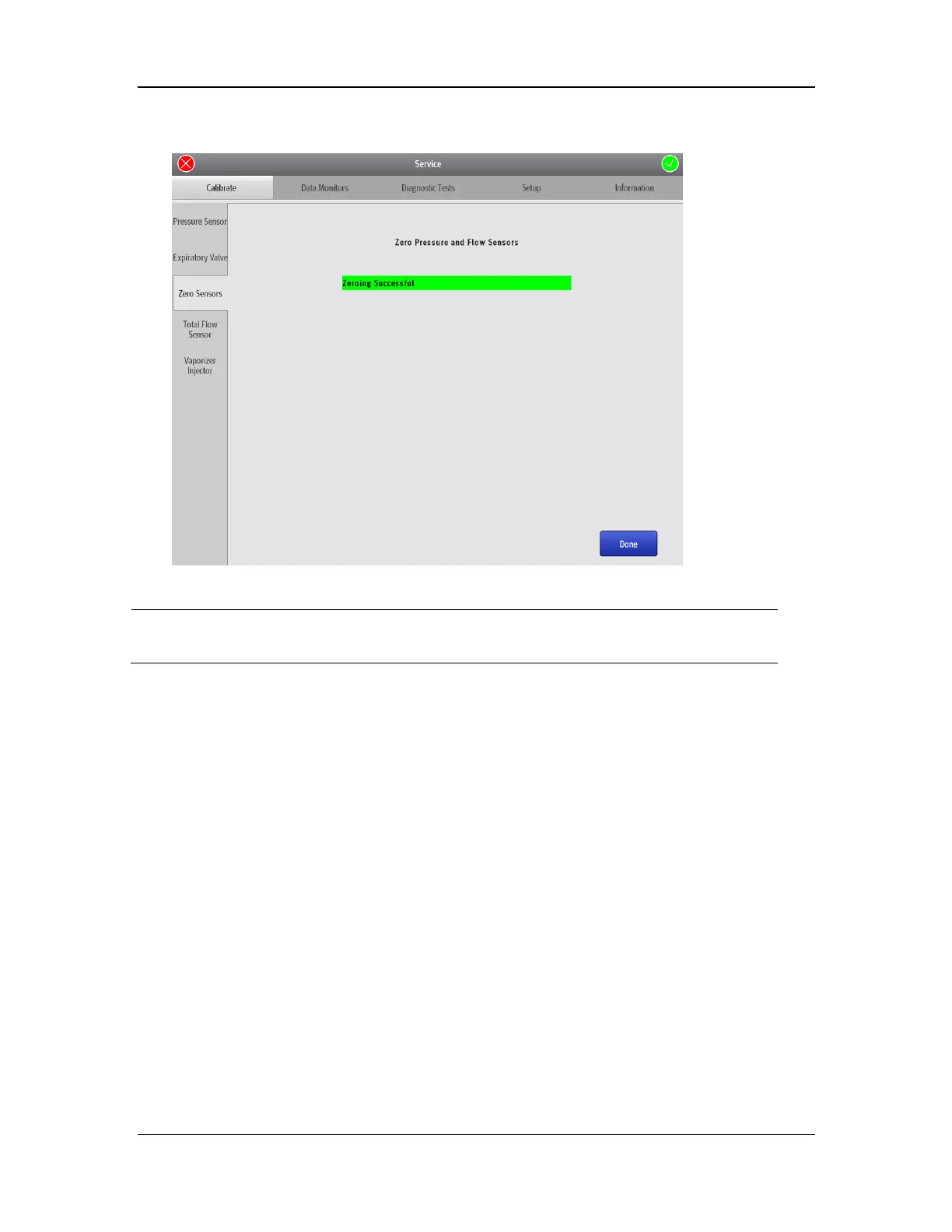

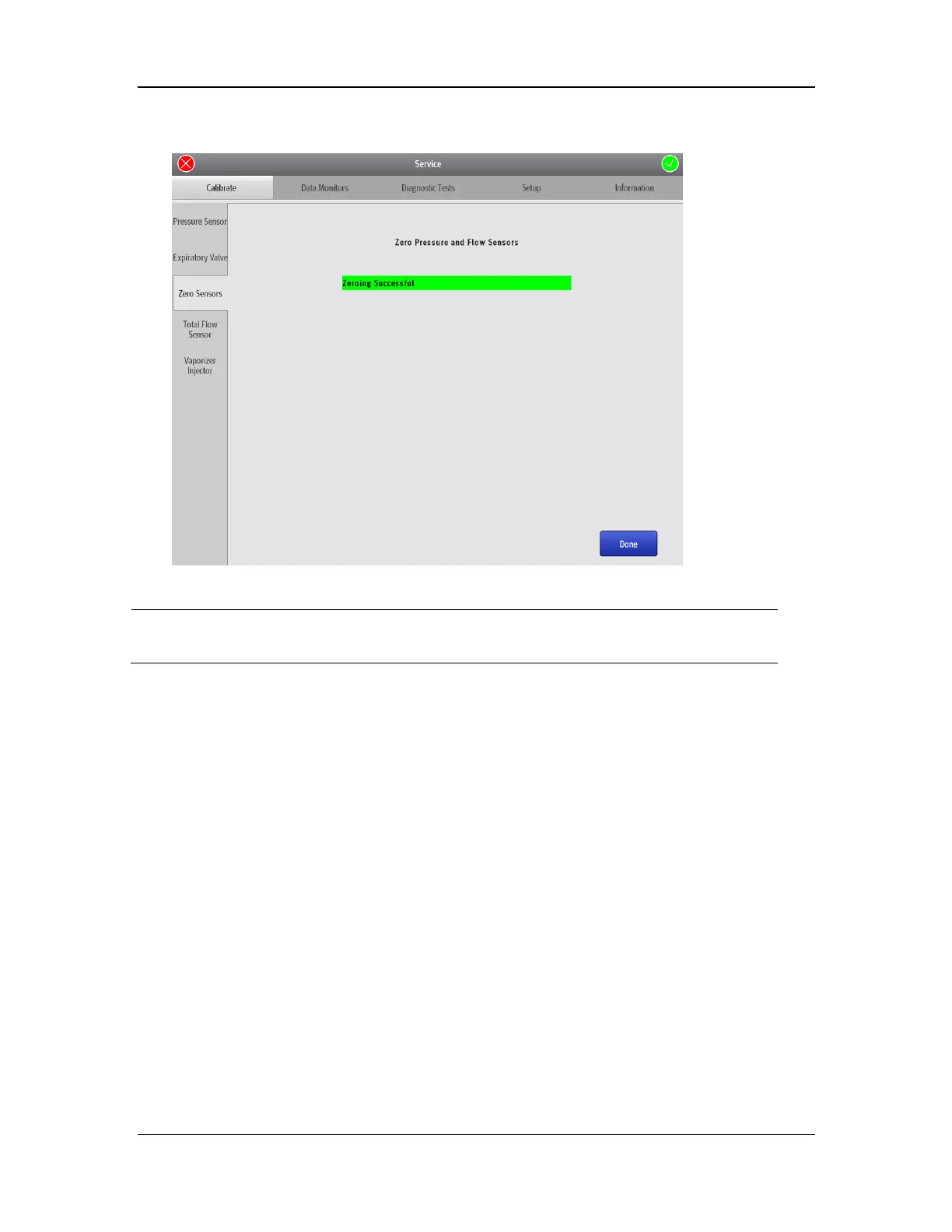

5. The screen shown below is displayed upon successful zeroing. Select Done to exit the zeroing

screen.

Other faults may exist in the machine if the zeroing fails. You must locate and

rectify the faults.

6.3.7.3 Zeroing Failure Troubleshooting

If the zeroing fails, perform the following steps to locate and rectify the fault.

1. Disconnect all gas supplies. Remove breathing tubes from the breathing system so that the

inspiratory and expiratory connectors are exposed in the air. Adjust the fresh gas flows to the

maximum, wait 10s, and turn off all fresh gas flows. Start the valve diagnosis tool. Ensure that no

flow or pressure enters the flow or pressure sensor inside the machine.

2. Check whether the zero points of sensors are abnormal (the values are in red font).

3. If a zero point error is detected, remove the sampling line from the sensor to eliminate effects

caused by the sampling line occlusion or three-way valve. If the zero point is still incorrect, the

VCM is faulty. Replace the VCM.

4. If the zero points of sensors are correct but zeroing still fails, the three-way valve assembly is

faulty. Replace the three-way valve assembly.

6.3.8 Total Flow Sensor Calibration (Service)

6.3.8.1 Principles

To support flow sensor self-test, it is necessary to find out the relationship of N2O measurement

between the O2 flow sensor in the total limb and the flow sensor in the N2O limb. Therefore, it is

necessary to vent in N2O to the machine to calibrate the O2 flow sensor in the total limb. This

operation is performed manually.

Loading...

Loading...