6-47

The calibration principles are as follows: When the EFCS opens the proportional valve in the

N2O limb with a fixed flow for a period of time, read the N2O measured value by the O2 flow

sensor in the total limb. After averaging for a certain period of time, this average value and the

N2O measured value by the flow sensor in the N2O limb form a data point in the calibration table

and so on. The points after calibration is completed form a calibration table.

6.3.8.2 Precautions

Ensure that the N2O supply is connected and its pressure is within the normal

range.

Ensure that the machine is in the EFCS state.

Ensure that the machine is in the EFCS state. Connect the N2O supply and

ensure the gas supply pressure is within the normal range. In the manual test of

the FCS test menu, open the N2O valve to make the measured value of the N2O

flow sensor become 0, 0.5, 1, 2, 4, 6, 8, and 10 respectively. Then observe whether

the value of each point measured by the flow sensor in the total limb is within the

accuracy range, and calibrate the value if it exceeds the accuracy range.

6.3.8.3 Calibration Procedure

Perform the following steps to calibrate flow sensors.

1. Enter the standby mode.

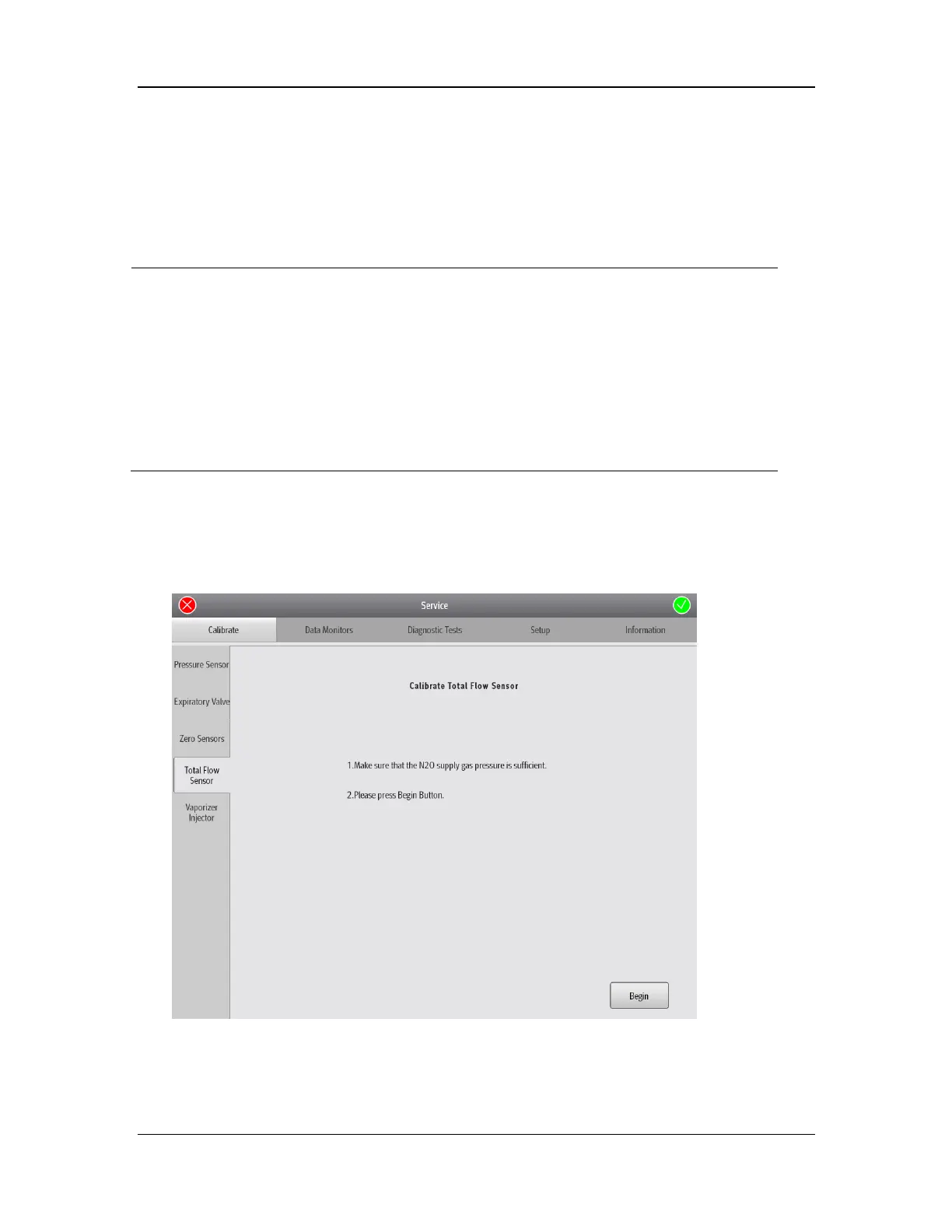

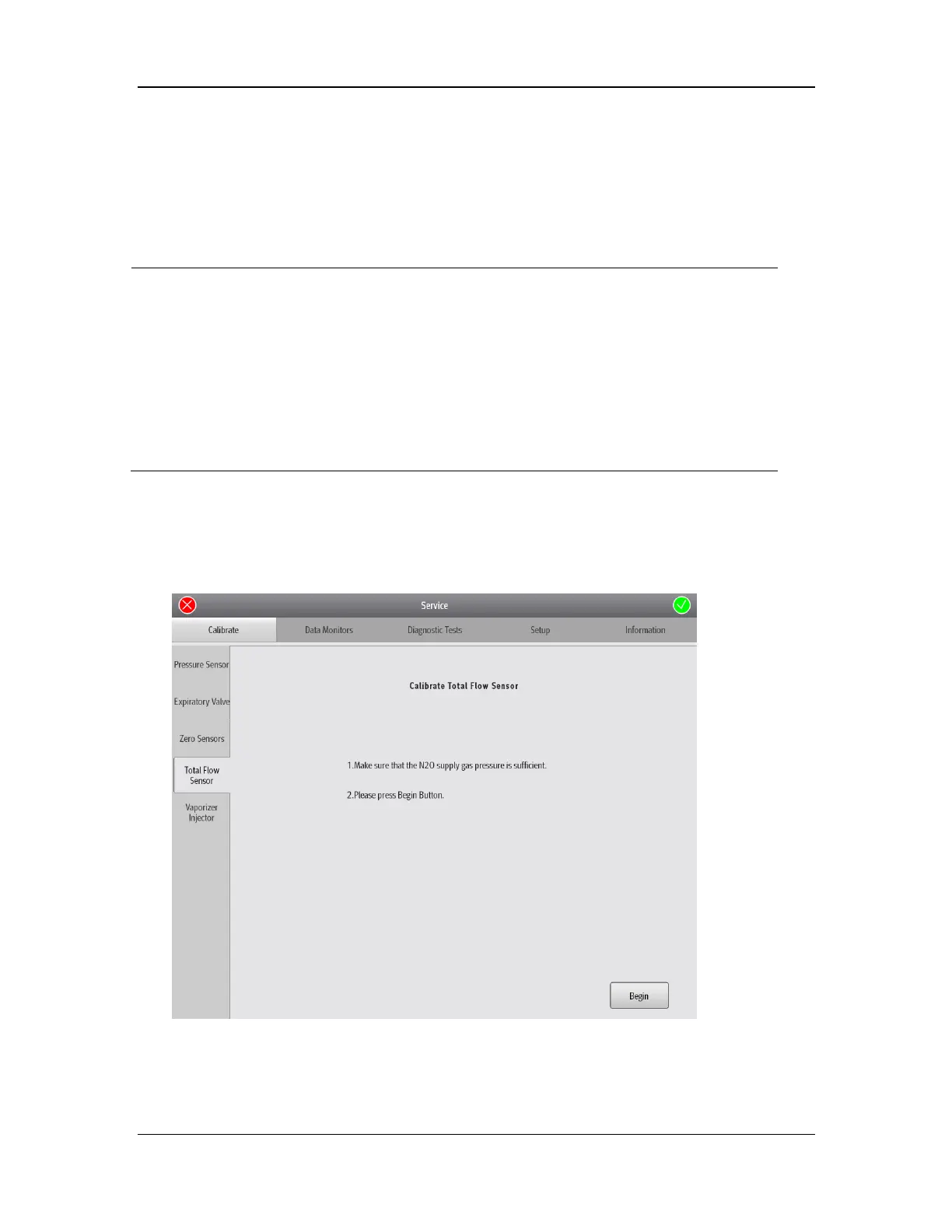

2. Select Setup > Service > Calibrate > Total Flow Sensor to access the screen shown below.

Loading...

Loading...