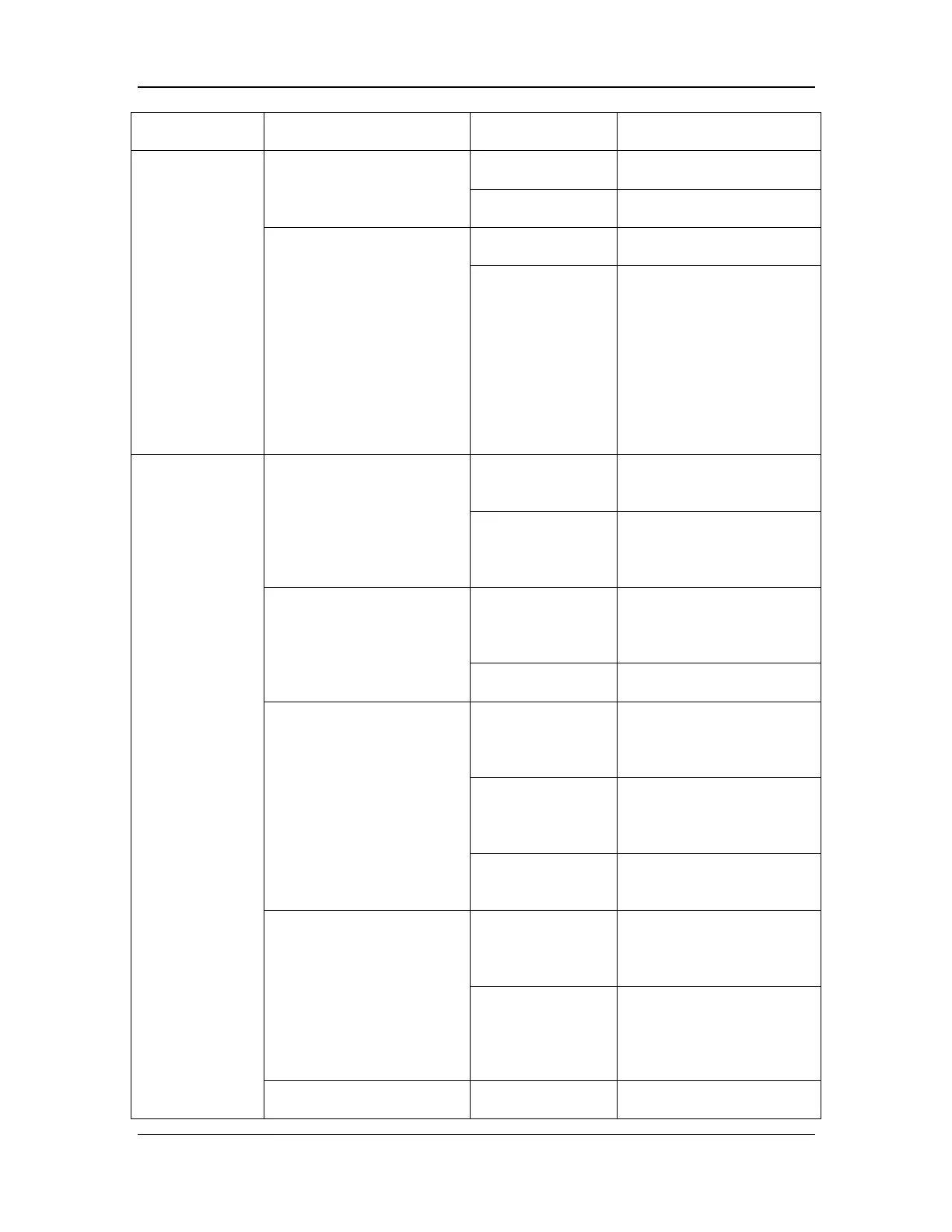

7-53

Cause Confirmation

Solution

board and its cables (refer to

11.4.1).

The vaporizer

cannot be started.

Proceed with step 3 to

continue with the check.

3. After the vaporizer is

installed in place, select

Setup > Service > Data

Monitors > Status Monitor

to access the data

monitoring screen and check

the vaporizer status.

The vaporizer

status is ON.

Replace the electronic

vaporizer.

The vaporizer

status is OFF.

(1) Replace the electronic

vaporizer.

(2) Replace the electronic

vaporizer base interface

board and its cables (refer to

11.4.1).

(2) If the problem persists,

replace the monitoring and

controlling assembly (refer

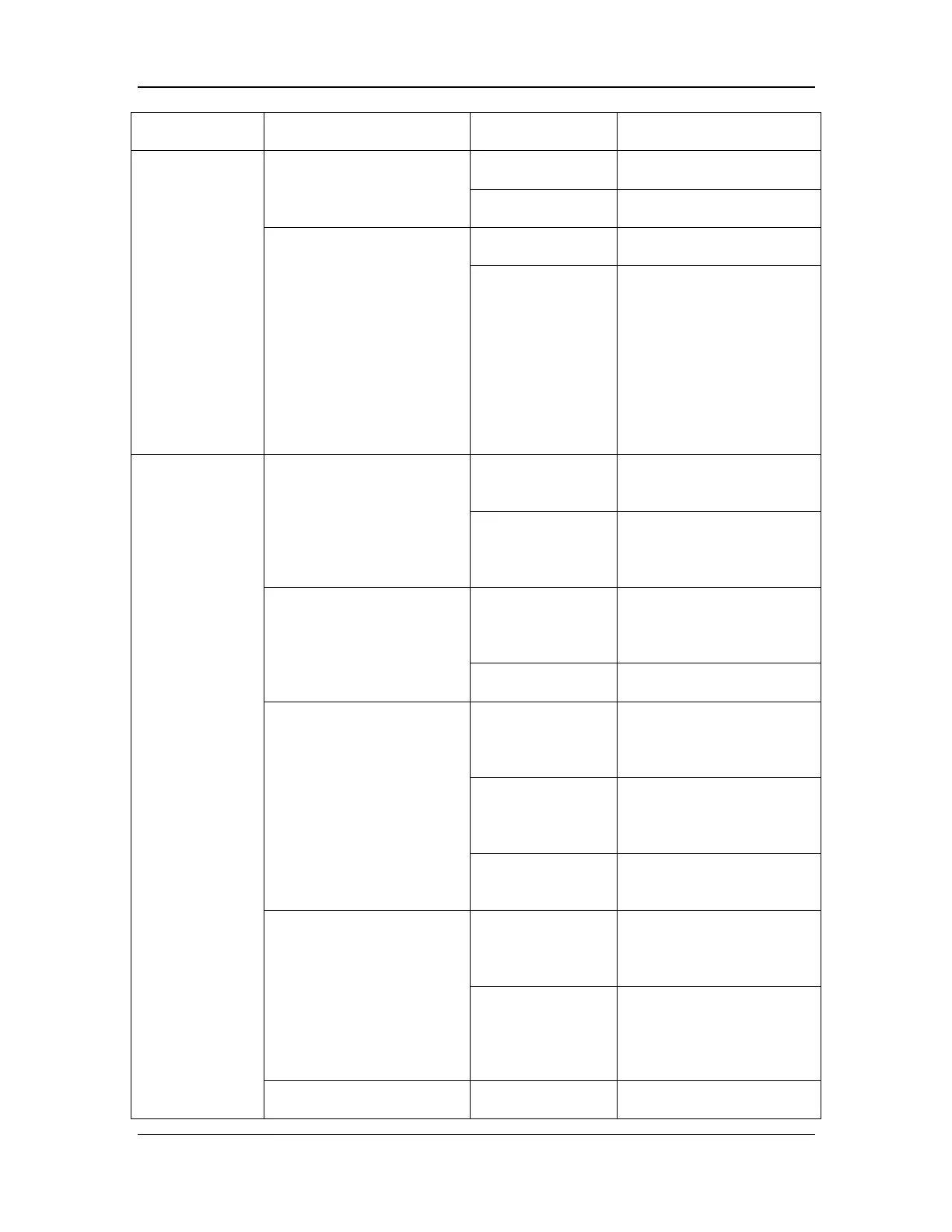

Vaporizer

activation failure

with successful

self-test

1. Check whether the gas

supply is sufficient.

pressure is less than

Connect or replace the gas

supply.

pressure is greater

than 280 kPa (40

Proceed with step 2.

2. Install the electronic

vaporizer in another slot and

try to activate it.

The vaporizer can

be activated.

vaporizer base interface

board and its cables (refer to

The vaporizer

cannot be activated.

Proceed with step 3 to

continue with the check.

3. Without connecting the

vaporizer, set the drive gas

3-way valve to ON, observe

the status signal of the drive

gas 3-way valve on the left

the UI, and check whether

drive gas is output from the

manifold connector (refer to

4.6.6).

drive gas 3-way

valve is ON, but no

Replace the vaporizer base

valve assembly (refer to

11.4.1).

drive gas 3-way

valve is ON, and

Proceed with step 4.

drive gas 3-way

Replace the vaporizer base

valve assembly (refer to

4. Connect the vaporizer.

Check whether the value of

the pressure sensor is 0

when the drive gas 3-way

valve is set to OFF and is

within 150±5 kPa (22±0.7

psi) when the drive gas

3-way valve is set to ON

pressure sensor is

within 150±5 kPa

Replace the electronic

vaporizer.

The value of the

pressure sensor is

beyond 150±5 kPa

(22±0.7 psi).

Proceed with step 5.

5 Open the service door

(refer to 8.1.1) and measure

The output pressure

is within 150±5

Replace the electronic

vaporizer.

Loading...

Loading...