19 Maintenance of robot program

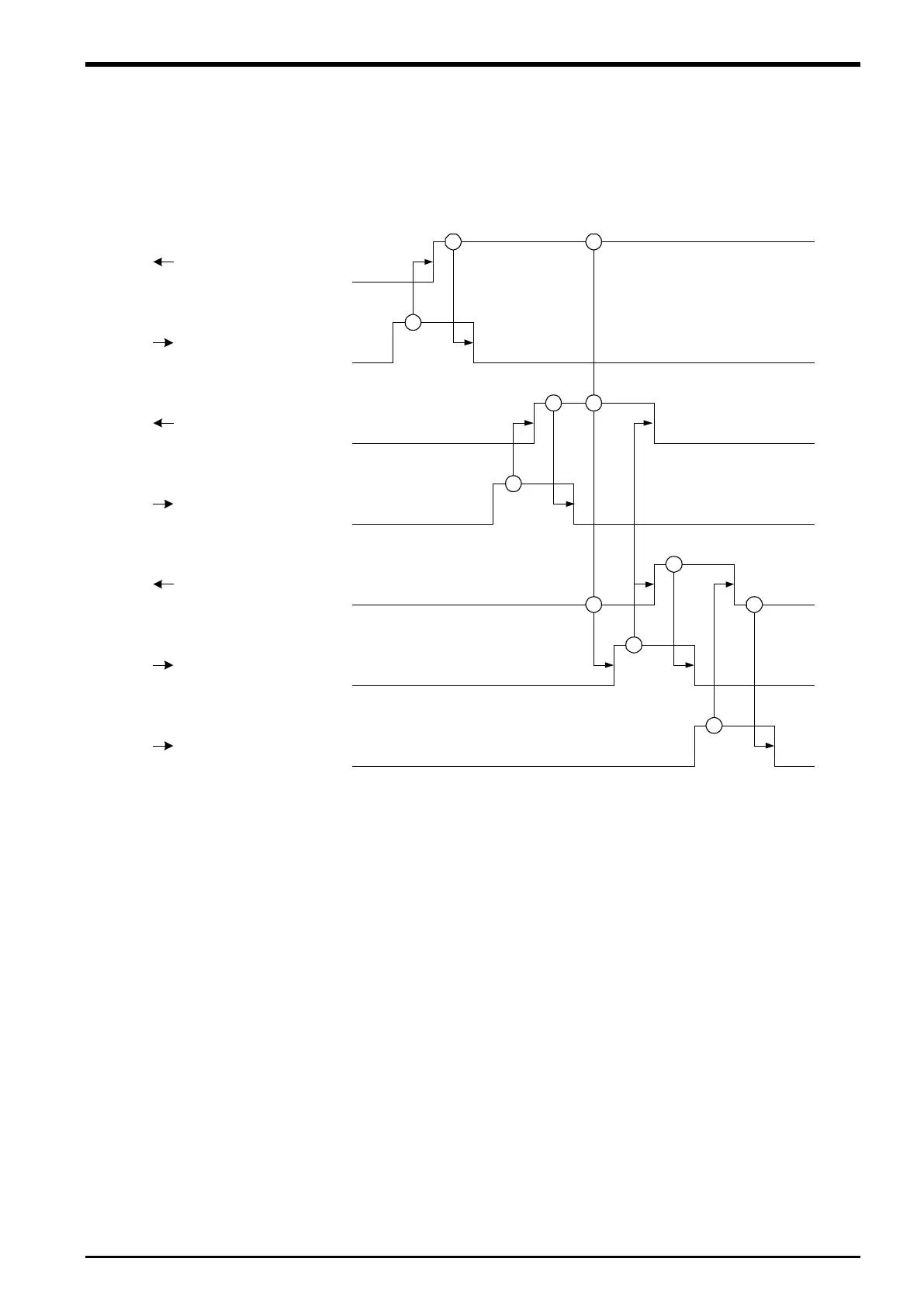

19.2. Timing Diagram of Dedicated Input/Output Signals

19.2.1. Robot Program Start Processing

The signal timing when a robot program is started from an external device is shown below.

Robot

PLC

Turning servo ON

(SRVON)

Servo ON

(SRVON)

Program selectable

(SLOTINIT)

Program reset

(SLOTINIT)

Operating

(START)

Start

(START)

Stop

(STOP)

H

L

① ② ③ ④

H

L

H

L

H

L

H

L

H

L

H

L

PLC sets “servo ON H” when it detects “turning servo ON L.” The robot turns the servo power supply on

and sets “turning servo ON H.” PLC acknowledges “turning servo ON H” and sets “servo ON L.”

PLC sets “program reset H” upon receiving “program selectable L.” The robot returns to the beginning of

the program and sets “program selectable H” when the program becomes ready to be started. PLC sets

“program reset L” when it detects “program selectable H.”

PLC acknowledges “turning servo ON H,” “program selectable H” and “operating L” and sets “start H.”

The robot sets “program selectable L” and “operating H” when it detects “start H.” PLC confirms

“operating H” and sets “start L.”

If a stop signal is input, the following processing is performed.

Upon receiving “stop H” from PLC, the robot sets “operating L.”

Timing Diagram of Dedicated Input/Output Signals 19-97

Loading...

Loading...