19 Maintenance of robot program

19. Maintenance of robot program

This chapter explains information required when maintaining the sample programs (robot program language

MELFA-BASIC V and dedicated input/output signals).

19.1. MELFA-BASIC V Instructions

The lists of instructions, status variables and functions related to tracking operation are shown below.

Please refer to the separate manual “Detailed Explanations of Functions and Operations” for further

information about MELFA-BASIC V.

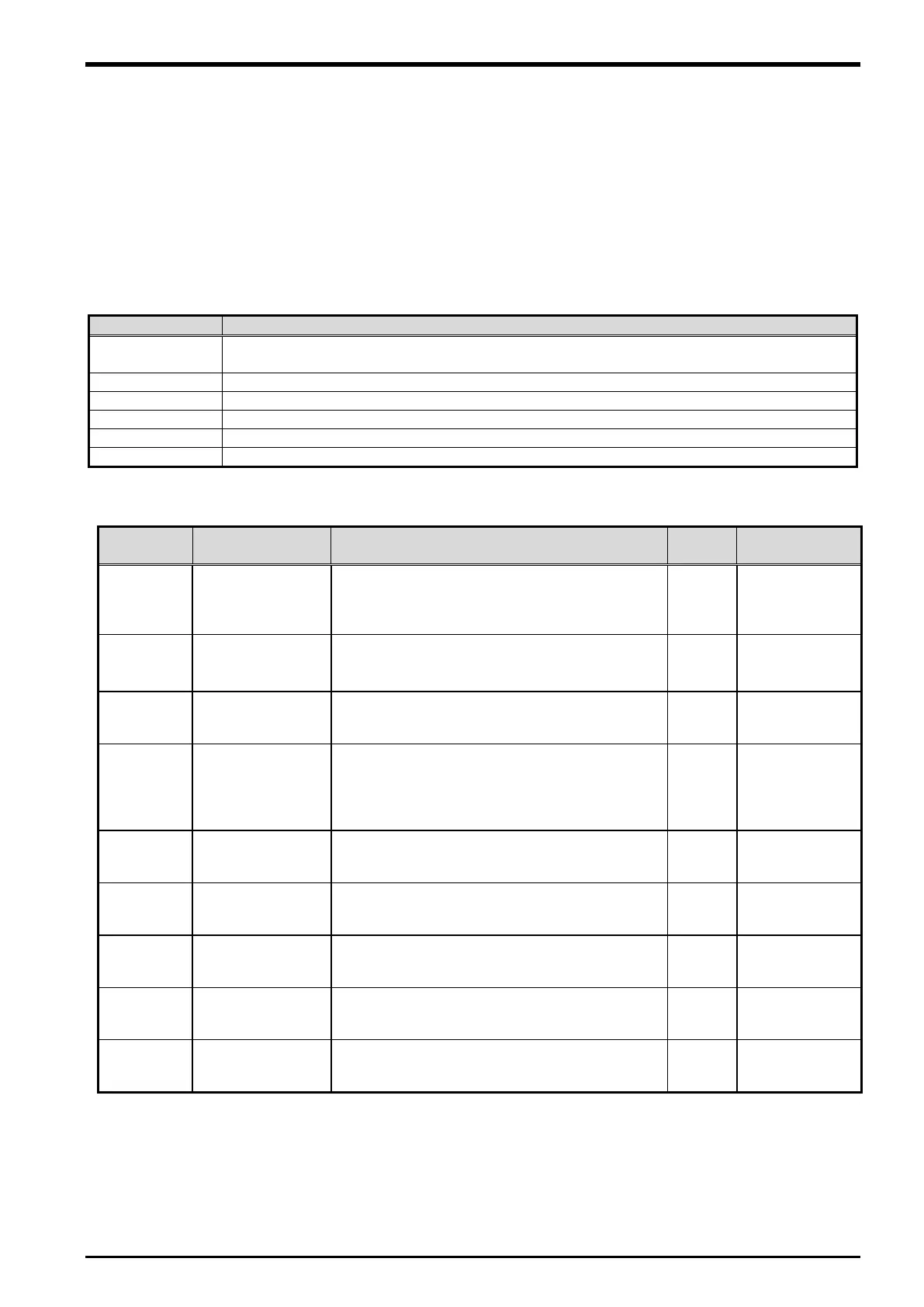

19.1.1. List of Instructions

Table 19−1 List of Instructions

Specify the workpiece coordinate origin of teaching data and tracking external encoder

logic number.

Clear the tracking data buffer.

Declare start and end of the tracking mode.

Output signals from a general-purpose output and read the encoder values.

Read workpiece data from the tracking data buffer.

Write workpiece data in the tracking data buffer.

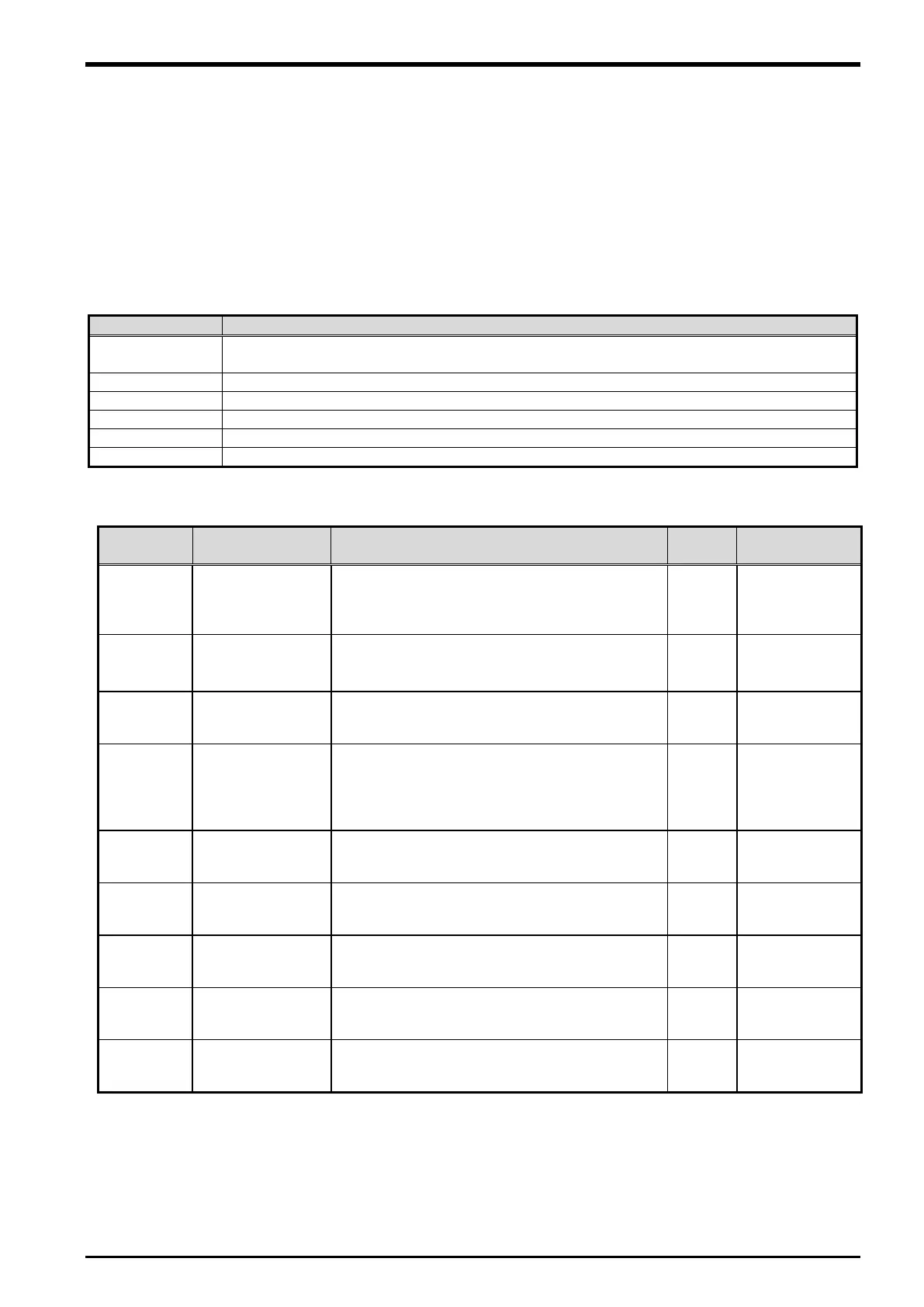

19.1.2. List of Robot Status Variables

Table 19−2 List of Robot Status Variables

Number of arrays Function

Data type

encoders

1 to 8

External encoder data can be rewritten.

If this state variable does not set parameter

“TRMODE" to “1", the value becomes like “0".

n real number

encoder

1

8

※

Possible to use from R1 and S1

※

n real number

encoders

Amount of robot movement per encoder pulse

*This state variable is made by sample “A1”

1 to The first

argument of

parameter

Number of data items stored in the tracking buffer

encoders

Conveyer speed (mm, rad/sec)

encoders

The maximum value of external encoder data

n real number

encoders

The minimum value of external encoder data

n real number

encoders

External encoder speed(Unit: pulse/sec)

real number

1 to 3

Tracking operation status of specified mechanism

1: Tracking

(*1)R: Only reading is permitted. R/W: Both reading and writing are permitted.

MELFA-BASIC V Instructions 19-87

Loading...

Loading...