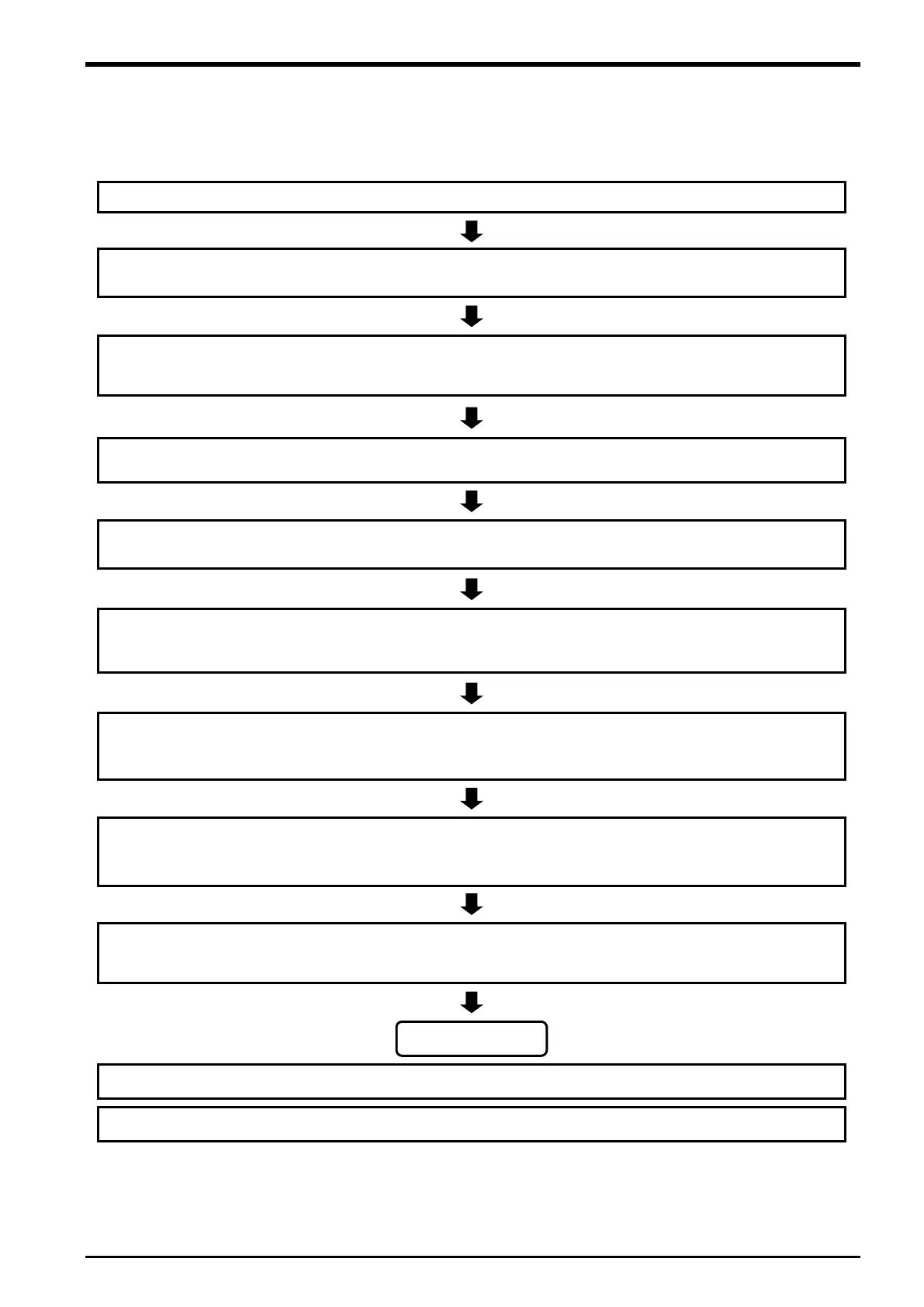

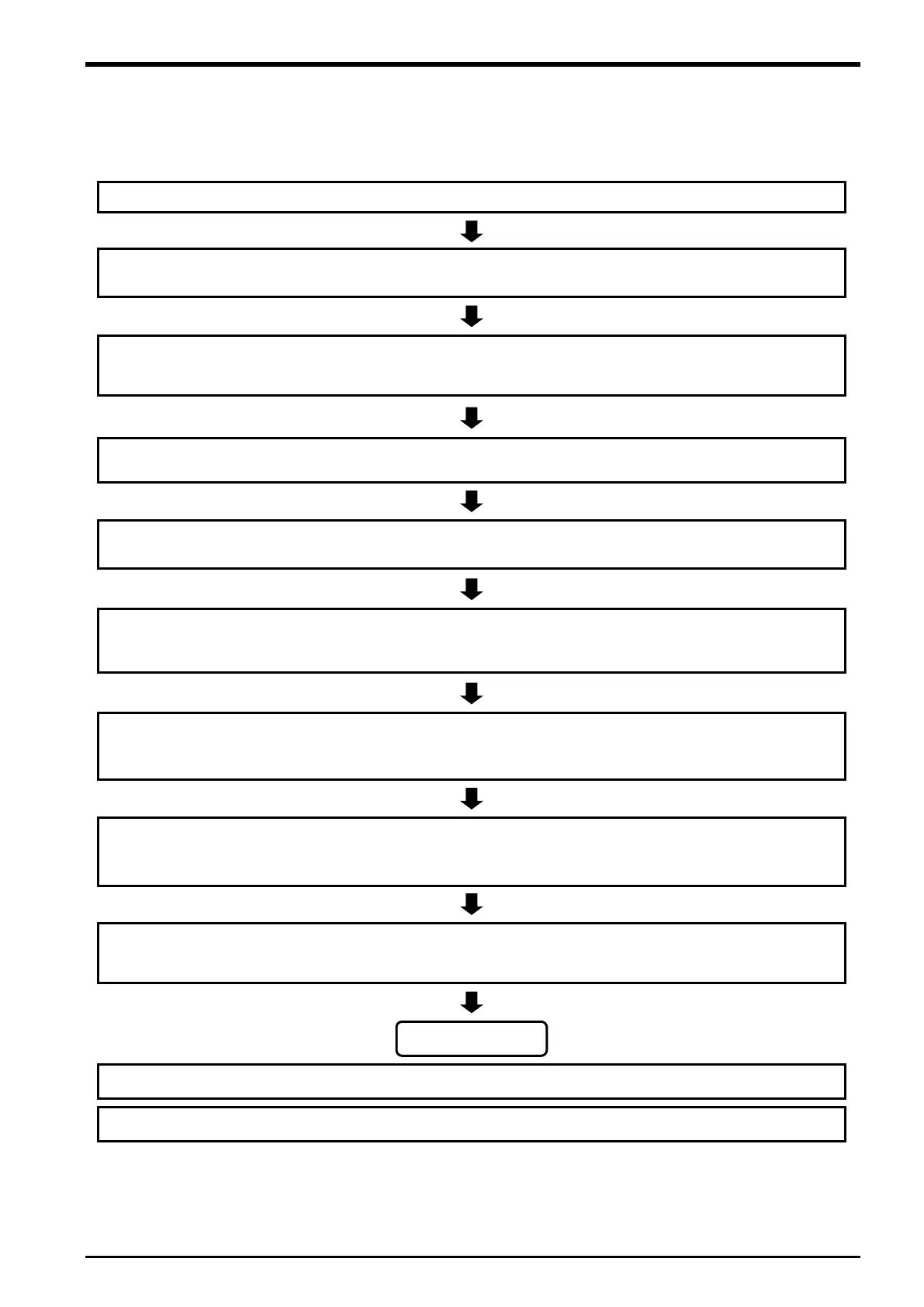

9 Operation Procedure

9. Operation Procedure

This chapter explains the operation procedure for constructing a conveyer tracking system and a vision

tracking system using Mitsubishi Electric industrial robots CR750-D/CR751-D series, CRnD-700 series.

4. Sample Robot Programs ····································································· Refer to “Chapter 12.”

Chapter 12 explains functions related to supplemental sample programs.

5. Calibration of Conveyer and Robot Coordinate Systems (“A1” program) ········ Refer to “Chapter 13.”

Chapter 13 explains how to calculate the amount of robot movement per encoder pulse.

7. Workpiece Recognition and Teaching (“C1” program) ································ Refer to “Chapter 15.”

Chapter 15

explains how to calculate the relationship between the position of a workpiece

recognized by the vision sensor and the position at which the robot grabs the workpiece.

9. Automatic Operation ··········································································· Refer to “Chapter 18.”

In automatic operation, the robot operates via commands from the conveyer control.

10. Maintenance ····················································································· Refer to “Chapter 19.”

11. Troubleshooting ··············································································· Refer to “Chapter 20.”

3. Parameter Setting ·············································································· Refer to “Chapter 11.”

Chapter 11 explains assignment of signals and setting of parameters related to tracking to allow an

external device to control a robot.

2. Connection of Equipment····································································· Refer to “Chapter 10.”

Chapter 10 explains installation of option cards and connection of an encoder.

8. Teaching and Setting of Adjustment Variables (“1” Program) ······················· Refer to “Chapter 16.”

Chapter 16 explains how to make settings such that the robot can follow workpieces moving by on a

conveyer and how to teach the robot origin and transportation destination at system start-up.

6.

Calibration of Vision Coordinate and Robot Coordinate Systems (“B1” program)

··· Refer to “Chapter 14.”

Chapter 14 explains how to display the position of a workpiece recognized by the vision sensor in

the robot coordinate system.

Tracking Specifications and Restriction matter 9-37

Loading...

Loading...