20 Troubleshooting

20. Troubleshooting

This section explains causes of error occurrence and actions to be taken.

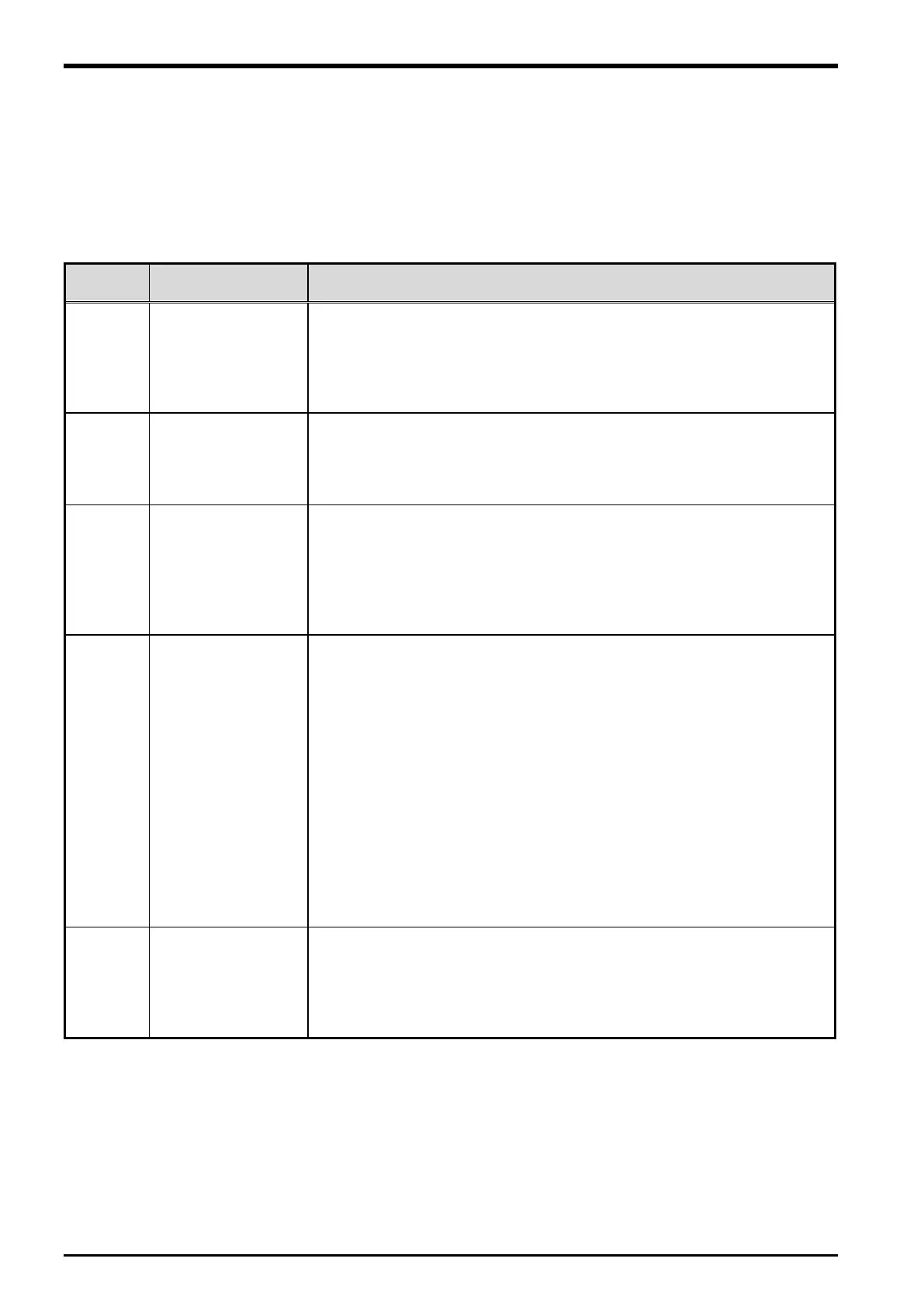

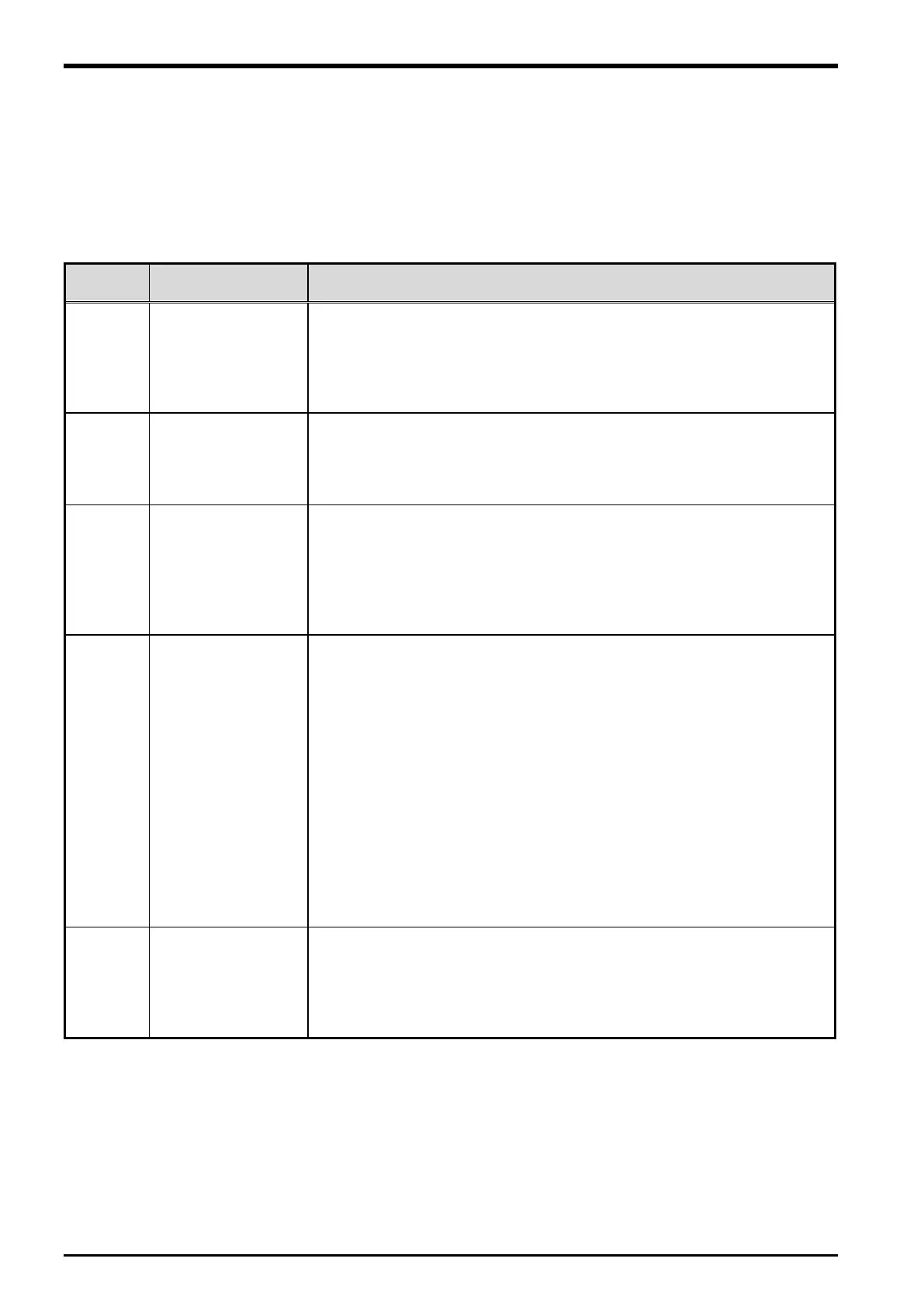

20.1. Occurrence of Error Numbers in the Range from 9000 to 9999

This section describes causes of errors that may occur while starting a program and how to handle them.

Table 20

−1 List of Errors in Sample Programs

Error description Causes and actions

error

The network vision sensor and the robot cannot be connected by the

“C1” program or the robot cannot log on the vision sensor.

[Actions]

1) Check the Ethernet cable which connects the robot with the network

of range

The encoder number specified in “A1” program to “C1” program is ”0”

or ”9” or larger.

[Actions]

1) Check the X coordinate of the position variable ”PE” in the programs.

range

The model number specified in “C1” program is ”0” or ”10” or larger.

[Actions]

1) Check the X coordinate of the position variable “PRM1” in “C1”

program.

2) If there are more than 11 models, change “MWKMAX=10” line in

out of range

The workpiece position calculated by operations in “A1” program to “C1”

program is very different from the theoretical value.

The example is shown in (*1).

[Actions]

1) Check the X and Y coordinates of the position variable ”PVTR” in

“CM1” program. These values represent the difference from the

theoretical value.

2) If the difference stored in “PVTR” is large, run “A1” program to “C1”

program again.

3) Please add the value of positional variable “PCHK" in the 'CM1'

program when the hand offsets from time when the calibration was

executed and add the amount of the offset.

4) Check that the X and Y coordinates of the position variable ”PCHK”

in “CM1” program are not ”0.” If they are ”0,” change the difference

from the theoretical value to an allowable value.

A return value cannot be created by the *S50WKPOS function of “1”

program.

[Actions]

1) Check the reason why “MY50STS” of the *S50WKPOS function in “1”

program does not change from”0”.

20-98 Occurrence of Error Numbers in the Range from 9000 to 9999

Loading...

Loading...