7 System Configuration

7.2. Example of System Configuration

The following figure shows examples of conveyer tracking systems and vision tracking systems.

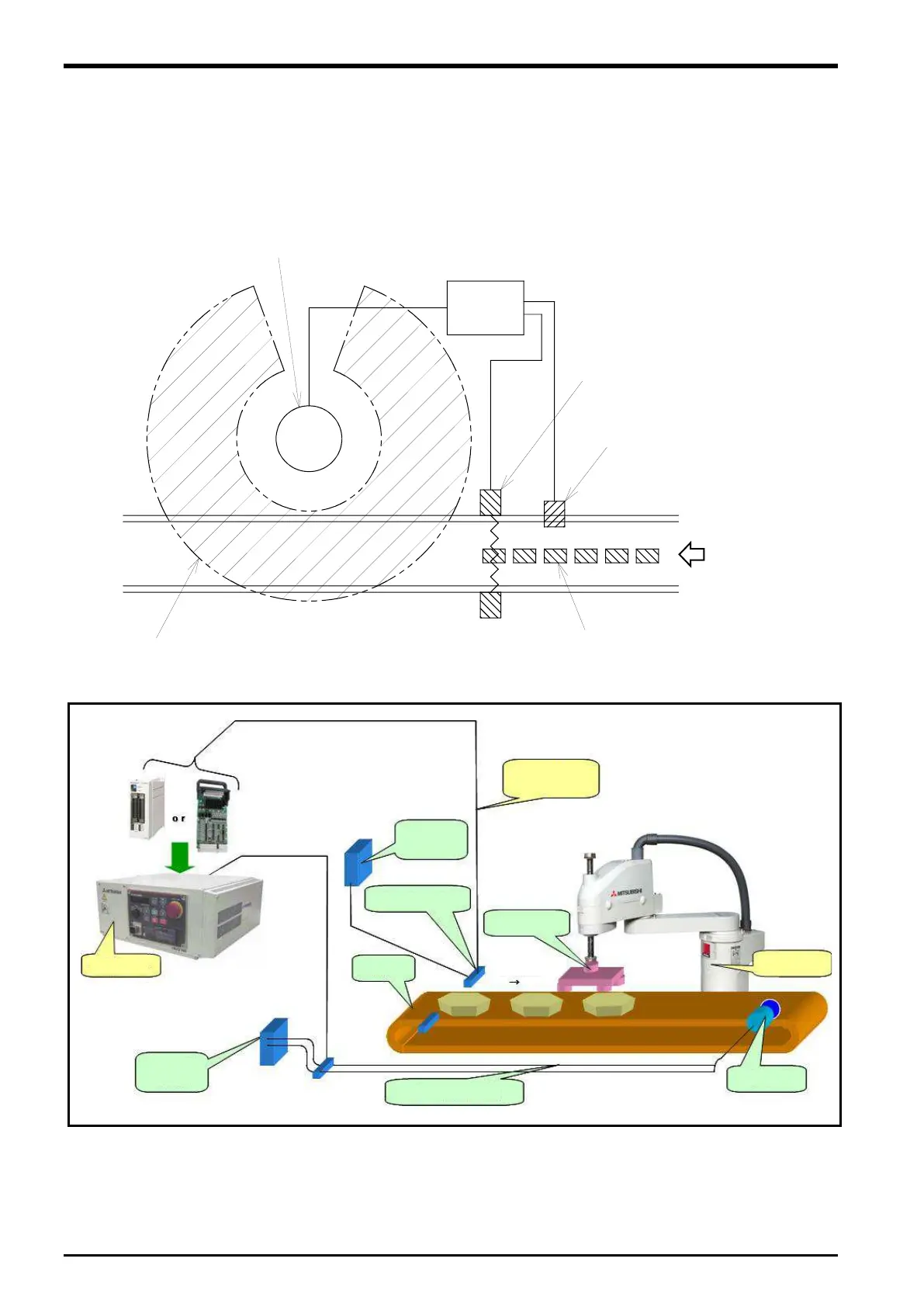

7.2.1. Configuration Example of Conveyer Tracking Systems

The following figure shows a configuration example of a system that recognizes lined-up workpieces on a

conveyer passing a photoelectronic sensor and follows the workpieces.

Figure

7-1 Configuration Example of Conveyer Tracking (Top View)

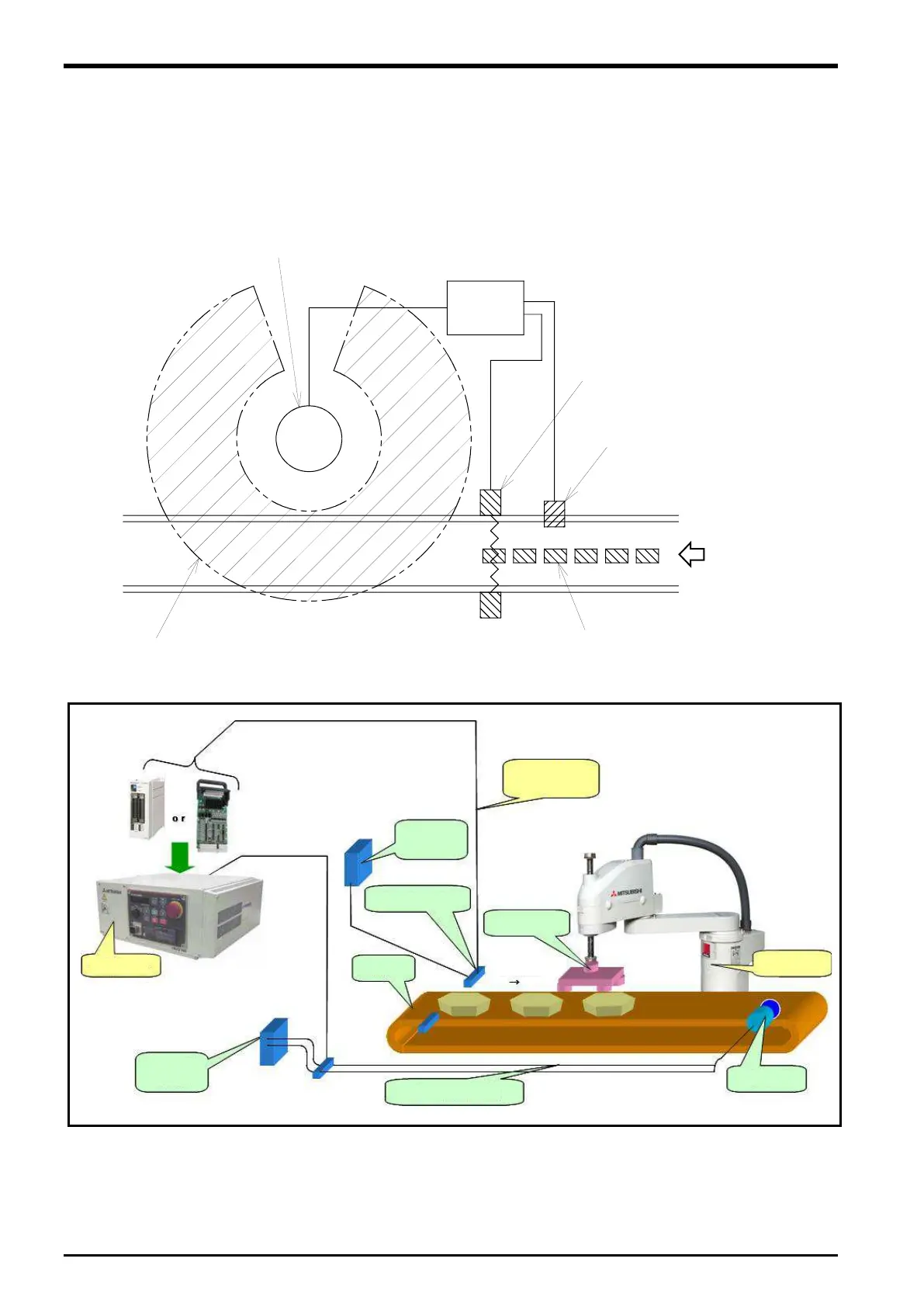

Figure

7-2 Configuration Example of Conveyer Tracking

)

)

Example of CR2D controller

*It is the same by other controller

Workpieces

flow direction

7-34 Example of System Configuration

Loading...

Loading...