6 Parameter Setting

6. Parameter Setting

This chapter explains how to set dedicated input/output signals that play the role of interface between a robot

and an external device (e.g., a Programmable Logic Controller) and parameters related to the tracking function.

Please refer to “Detailed Explanations of Functions and Operations” for how to set the parameters.

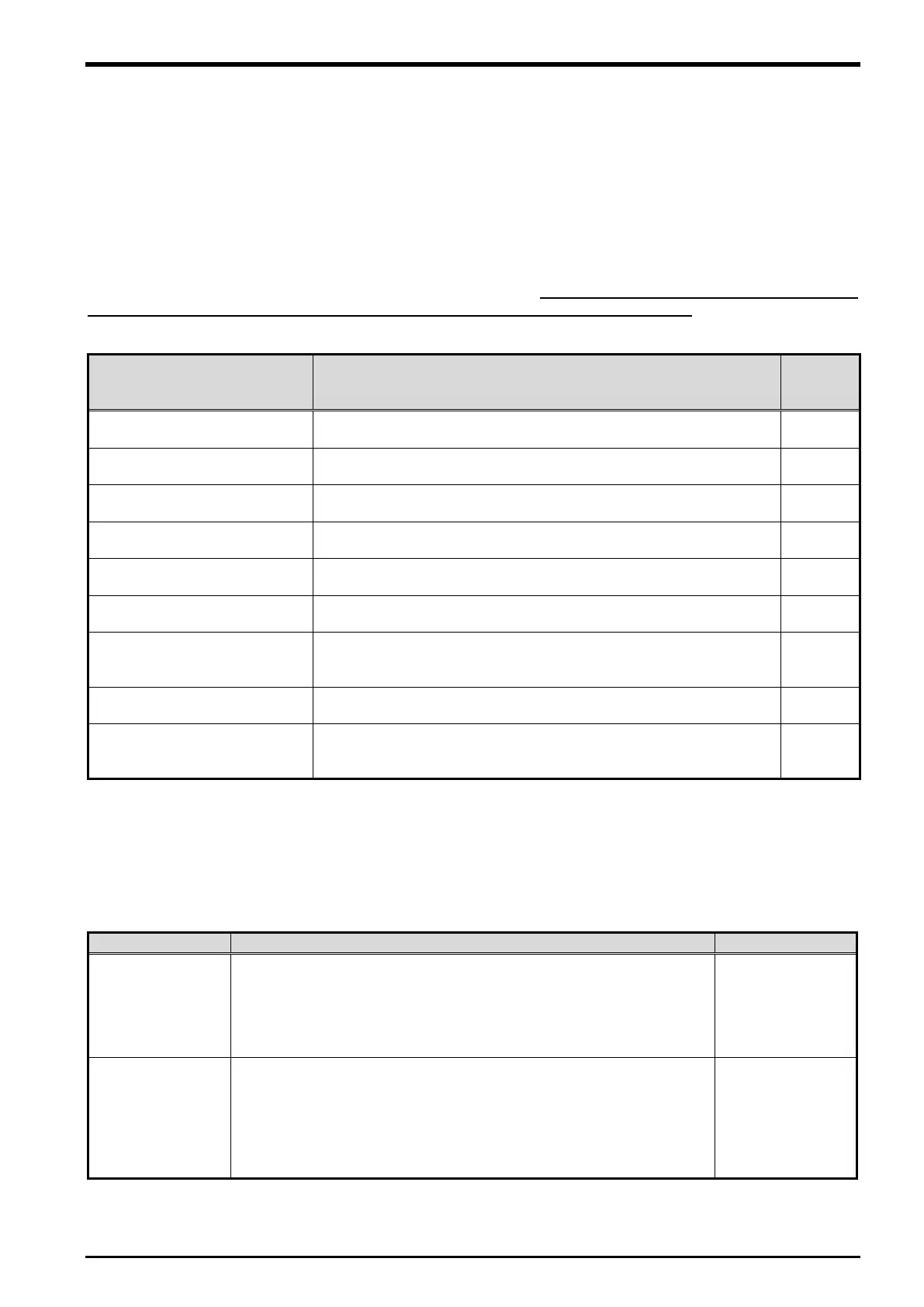

6.1. Dedicated Input/Output Parameters

“Table 11

−

1 List of Dedicated Input/Output Parameters” lists the setting items of dedicated input/output

parameters used to operate the robot via instructions from an external device. Set the signal numbers according

to your system using the setting values in the table as reference.

It is not necessary to set these parameters

if the robot operates by itself, rather than via instructions from an external device.

Table 6

−1 List of Dedicated Input/Output Parameters

Input name/output name

(parameter name)

Explanation

Example

Stop/pausing

(STOP) or (STOP2)

Input: Stop a program

Output: Output program standby status

Servo OFF/servo ON disabled

(SRVOFF)

Input: Turn the servo off

Output: Output servo ON disabled status

10011 ,

Error reset/error occurring

(ERRRESET)

Input: Cancel error status

Output: Output error status

10009 ,

Input: Start automatic operation

Output: Output program running status

Servo ON/turning servo ON

(SRVON)

Input: Turn the servo on

Output: Output servo on status

Operation right/operation right

enabled (IOENA)

Input: Enable/disable operation right of external signal control

Output: Output external signal control operation enabled status

10005 ,

selectable

Input: Initiate a program. The program execution returns to the

first step.

Output: Output a status where program No. can be changed

10008 ,

-1

General output signal reset

(OUTRESET)

Input: Reset a general output signal

10015 ,

User specification area 1

(USRAREA)

Output an indication that the robot is in an area specified by a

user

Set the start number and end number

10064,

10071

(*1) “-1” in the Setting value column means “not set.”

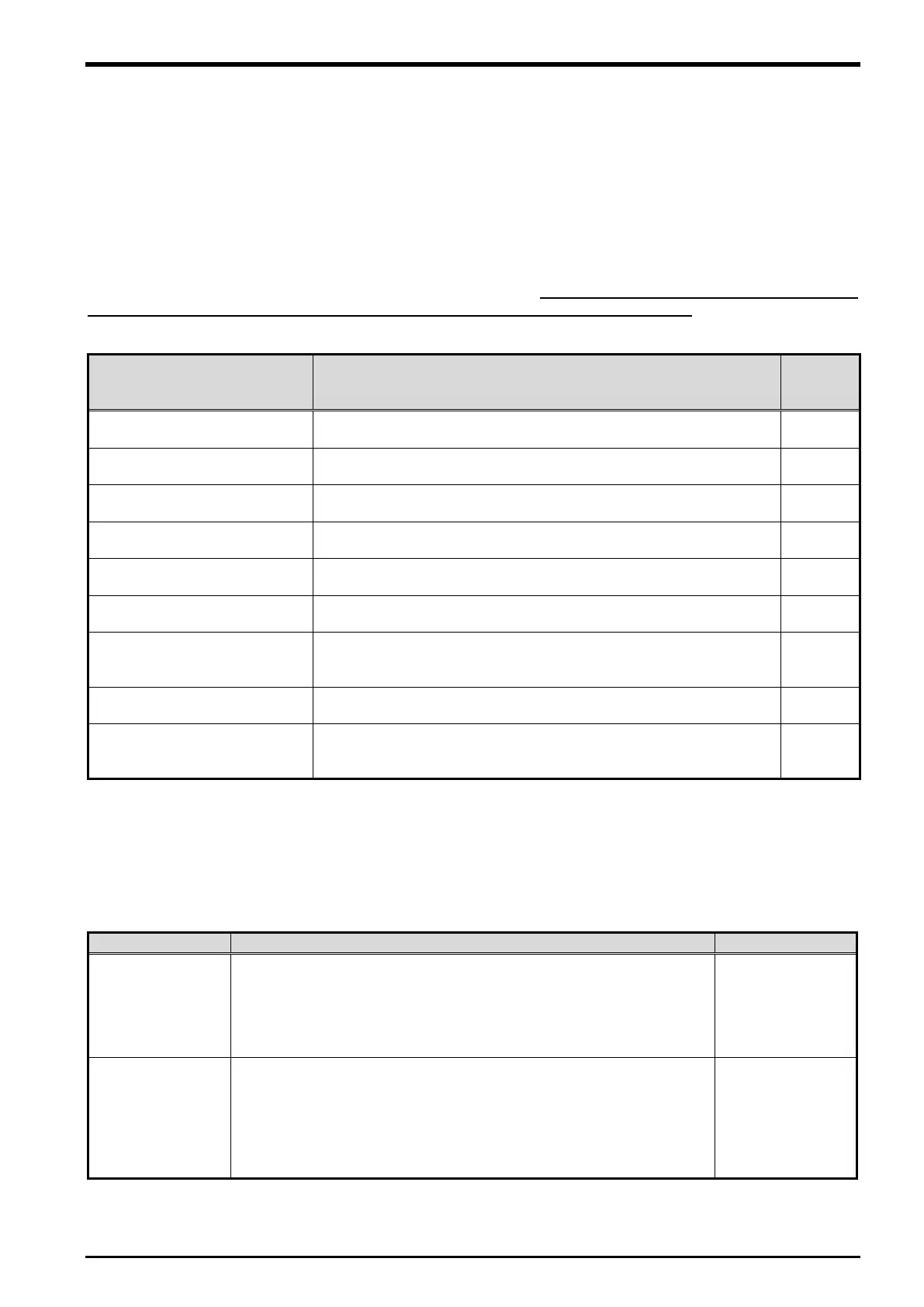

6.2.

Operation Parameters

“Table 11

−

2 List of Operation Parameter” lists the setting items of parameters required to operate the robot at

the optimal acceleration/deceleration.

Table 6

−2 List of Operation Parameter

acceleration/

deceleration hand

data

(HANDDAT1)

Specify hand weight and so on to make settings that allow optimal

acceleration/deceleration operations.

For example, if the hand weighs 3 kg, changing the weight setting

value from 10 kg to 3 kg makes the robot movement faster.

(Hand weight (kg), size (mm) X, Y, Z, gravity (mm) X, Y, Z)

The setting values

are different for

each robot model.

Use these values

acceleration/

deceleration

workpiece data

(WRKDAT1)

Specify workpiece weight and so on to make settings that allow

optimum acceleration/deceleration operations.

If a workpiece is grabbed via the HClose instruction, the

acceleration/deceleration becomes slower. If a workpiece is

released via the HOpen instruction, acceleration/deceleration

becomes faster.

(Workpiece weight (kg), size (mm) X, Y, Z, gravity (mm) X, Y, Z)

The setting values

are different for

each robot model.

Use these values

as reference only.

Dedicated Input/Output Parameters 6-25

Loading...

Loading...