13 Calibration of Conveyer and Robot Coordinate Systems (

“

A1

”

program)

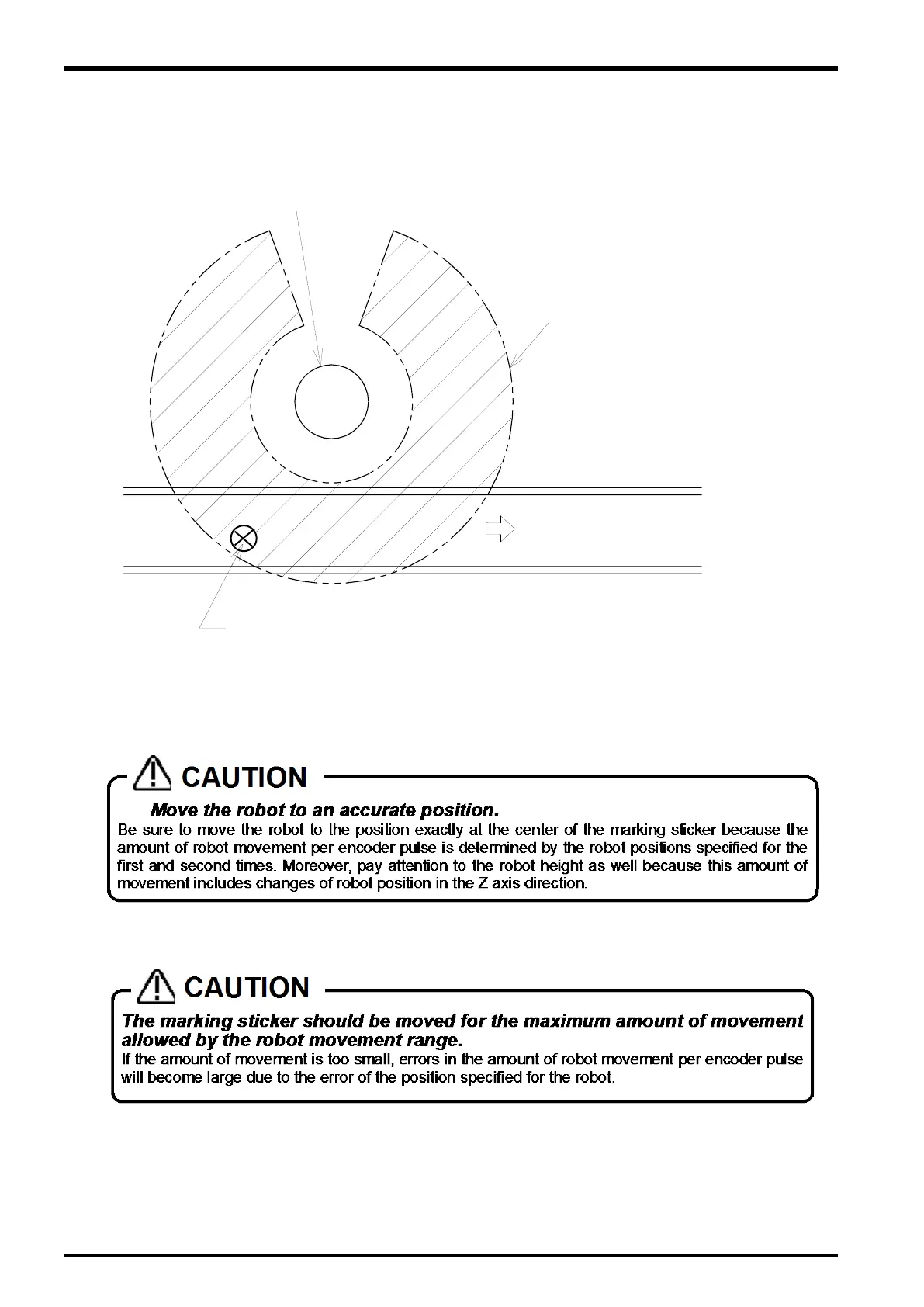

2) Attach a marking sticker on the conveyer (a sticker with an X mark is the best choice for the marking

sticker).

Drive the conveyer and stop it when the marking sticker comes within the robot movement range.

Figure 13

−2 Position of Marking Sticker on Conveyer

3) Move the robot to the position right at the center of the marking sticker on the conveyer.

* With this operation, encoder data and robot position are acquired.

4) Raise the robot.

5) Drive the conveyer and stop at a position where the marking sticker is immediately outside the robot

movement range.

6) Move the robot to the position right above the center of the marking sticker on the moved conveyer.

* With this operation, encoder data and robot position are acquired.

7) Raise the robot.

8) Perform step operation until “End.”

* The amount of robot movement per encoder pulse is calculated based on this operation.

13-52 Tasks

Loading...

Loading...