3 Specification

3. Specification

3.1. Tracking Specifications and Restriction matter

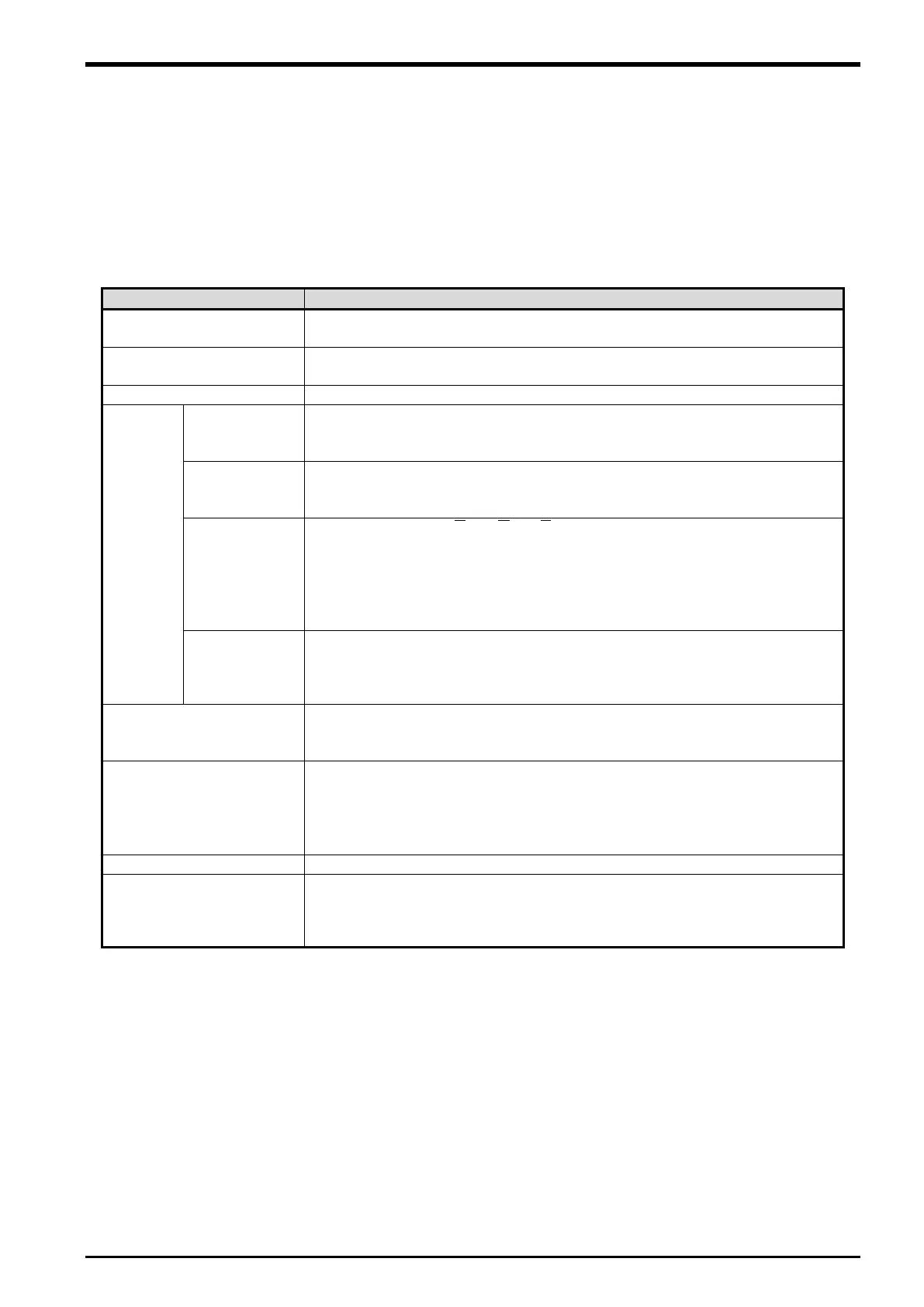

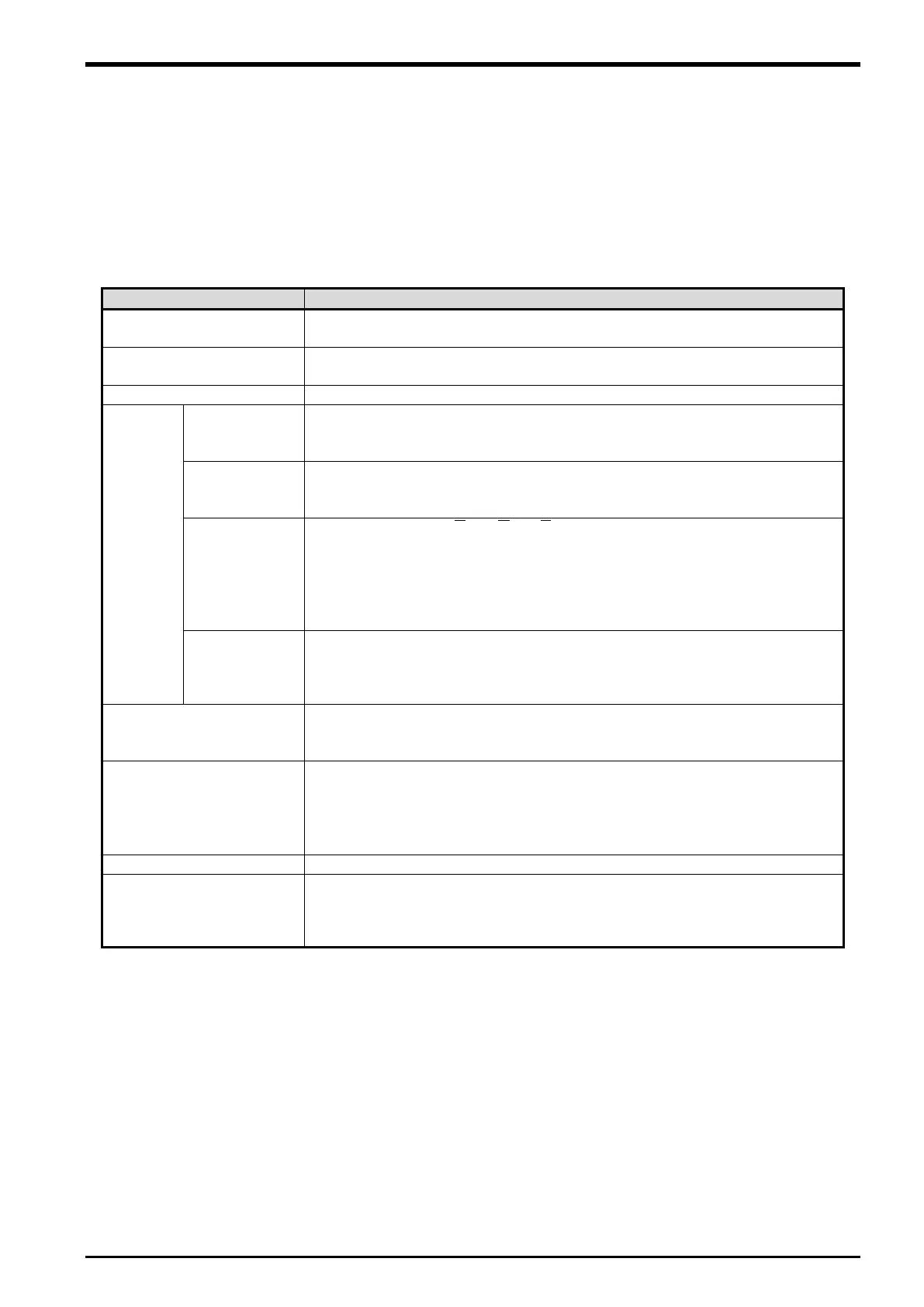

”Table 3−1 CR750-Q/CR751-Q Series, CRnQ-700 Series Controller Tracking Function Specifications”

shows the tracking specifications.

Please refer to “Standard Specifications Manual” for the specifications of the robot arm and controller to be

used.

Table 3−1 CR750-Q/CR751-Q Series, CRnQ-700 Series Controller Tracking Function Specifications

(*1) The specification values in the table should only be considered guidelines. The actual values

depend on the specific operation environment, robot model, hand and other factors.

(*2) The line driver output is a data transmission circuit in accordance with RS-422A. It enables the

long-distance transmission.

(*3) Please connect the output signal of a photoelectric sensor with the terminal TREN of the Q173DPX

unit. This input can be confirmed,by the input signal 810th-817th.

(*4) In the case of vision tracking, please refer to the instruction manual of network vision sensor.

(*5) The precision with which workpieces can be grabbed is different from the repeatability at normal

transportation due to the conveyer speed, sensor sensitivity, vision sensor recognition accuracy and

other factors. The value above should only be used as a guideline.

(*6) The encoder connected with the third channel of the Q173DPX unit specified for parameter

"ENCUNIT3" cannot be used.

(*7) Voltage output/open collector type is an output circuit with two output transistors of NPN and PNP.

(*8) The sample program doesn't correspond to the RV-5 axis robot.

Specification and Restriction matter

RH-SQH series / RV-SQ series

RH-FH-Q series / RV-F-Q series

Applicable robot controller

CR1Q / CR2Q / CR3Q controller

CR750-Q/CR751-Q series controller

Load commands dedicated for the tracking function

conveyer

(

in case 1pc encoder connect to 1 pc conveyer

)

Encoder 3 pcs / Q173DPX unit 1pc

Q173DPX unit 3pcs / system

Speed (*1)

Possible to support up to 300mm/s (When the robot always transport the

workpieces)

Possible to support up to 500mm/s when the interval of workpiece is wide.

:

Output form : Voltage output/open collector type (*7)

Line driver output (*2)

Resolution(pulse/rotation)) : Up to 2000 (4000 and 8000 uncorrespond))

Confirmed operation product : Omuron E6B2-CWZ1X-1000

2D-CBL05(External I/O cable 5m)

2D-CBL15(External I/O cable 15m)

[*] Two or more robots CPU cannot share one Q173DPX.

One Q173DPX is necessary for each robot CPU.

(*3)

Used to detect workpieces positions in conveyer tracking.

Output signal of sensor need to be connected to TREN terminal of

Q173DPX unit. (Input signal number 810~817)

And a momentary encoder value that the input enters is preserved in state

(

)

Mitsubishi’s network vision sensor

position (*5)

Approximately ±2 mm (when the conveyer speed is approximately 300

mm/s)

(Photoelectronic sensor recognition accuracy, vision sensor recognition

accuracy, robot repeatability accuracy and so on)

Tracking Specifications and Restriction matter 3-11

Loading...

Loading...