6 Parameter Setting

6.3. Tracking Parameter Setting

Specify to which channel of the encoder connector (CNENC) an encoder of conveyer is connected.

“Table 6-3 Tracking Parameter Setting” lists the parameters to be set. Other parameters are shown in “Table

21-1 List of Tracking Parameters”, make settings as required.

6.3.1. Robot Parameter Setting

After the installation of Q173DPX module and connection with the encoder are complete, use the following

steps to establish robot CPU parameters.

(1) Using parameter ENCUNT* (*=1~3), designate the slot in which Q173DPX module under the control of robot

CPU is installed.

(2) Change the number of the incremental synchronization encoder being physically wired into a logic number,

using parameter EXTENC.

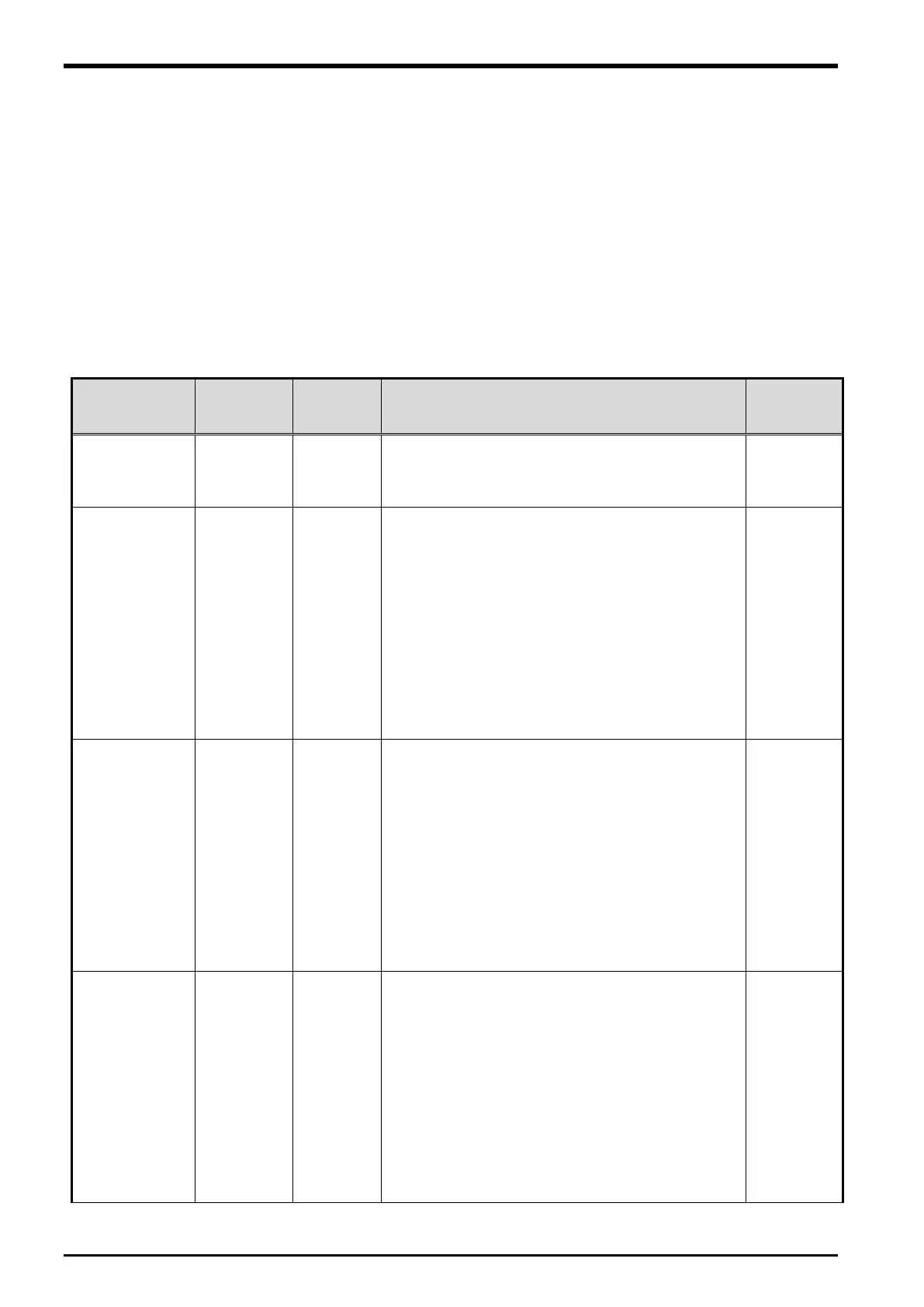

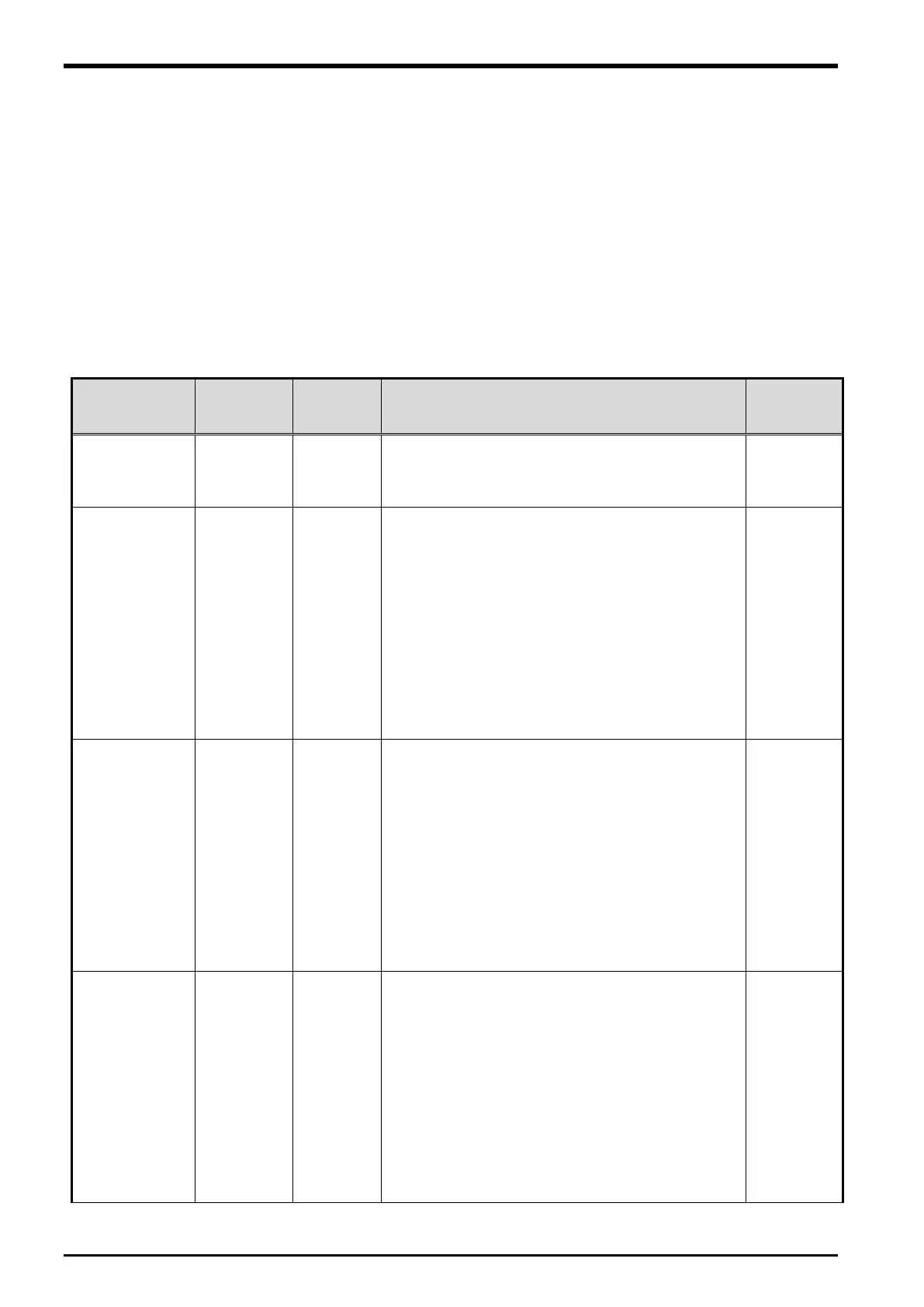

Table 6-3

Tracking Parameter Setting

Parameter

Parameter

name

Number of

elements

Explanation

at factory

Enable the tracking function

Please set it to “1" when you use the tracking

function.

The base unit-number of the first Q173DPX unit

(element 1) that robot CPU manages and slot

number (element 2) are set.

【

Element

1】

-1

:

No connection

0

:

Basic base unit

1~7

:

Increase base unit

【

Element

2】

0~11

:

I/O Slot number

*

This parameter is valid in the following

software versions.

・

CRnQ-700 series: Ver. R1 or later

Q173DPX

The base unit-number of the second Q173DPX

unit (element 1) that robot CPU manages and slot

number (element 2) are set.

【

Element

1】

-1

:

No connection

0

:

Basic base unit

~7

:

Increase base unit

【

Element

2】

0~11

:

I/O slot number

*

This parameter is valid in the following

software versions.

・

CRnQ-700 series: Ver. R1 or later

The base unit-number of the third Q173DPX unit

(element 1) that robot CPU manages and slot

number (element 2) are set.

【

Element

1】

-1

:

No connection

0

:

Basic base unit

~7

:

Increase base unit

【

Element

2】

0~11

:

I/O slot number

*

This parameter is valid in the following

software versions.

・

CRnQ-700 series: Ver. R1 or later

6-26 Tracking Parameter Setting

Loading...

Loading...