16 Teaching and Setting of Adjustment Variables (

“

1

”

Program)

16.2. Setting of adjustment variables in the program

The following section explains how to set adjustment variables, which are required at transportation, and

details about their setting.

Please refer to separate manual “Detailed Explanations of Functions and Operations” for how to set

adjustment variables.

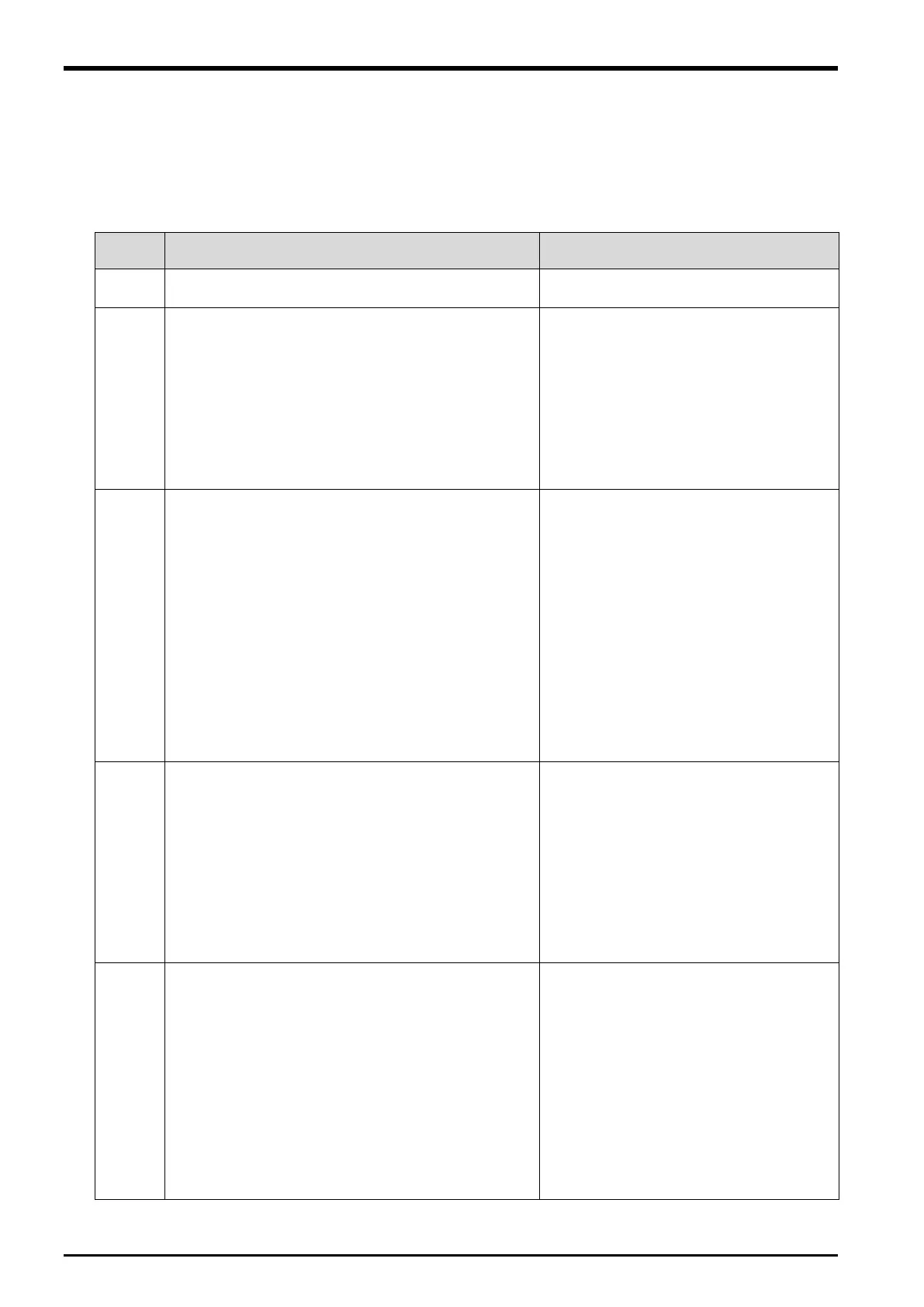

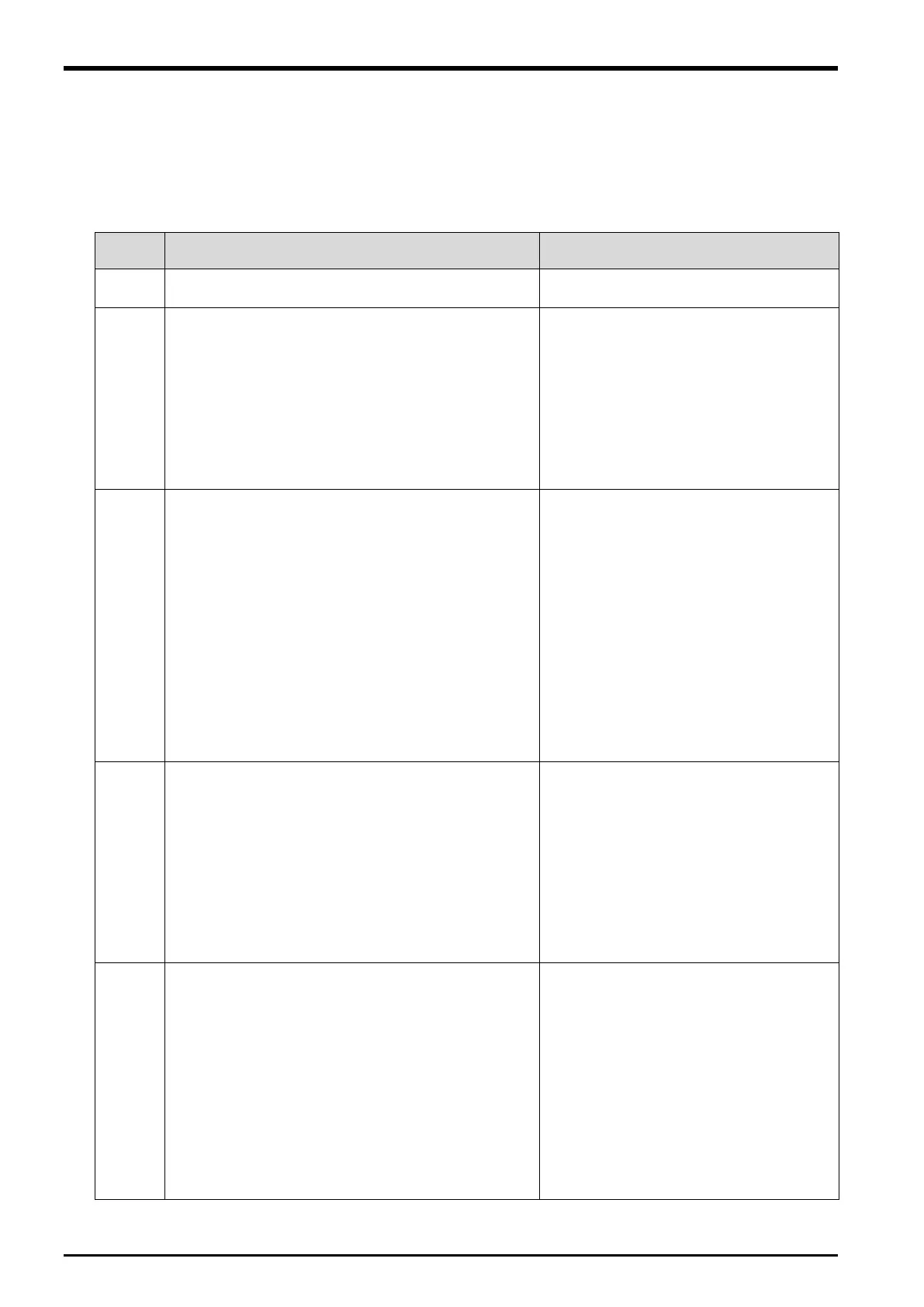

Table 16

−1 List of Adjustment Variables in Programs

Explanation Setting example

Set the model number.

X = model number (1 to 10)

When you set 1 to the model number:

(X, Y, Z, A, B, C) =(+1,+0,+0,+0,+0,+0)

“1” program and “CM1” program are run

simultaneously (multitasking). “1” program moves the

robot, and “CM1” program observes the sensor.

It is possible to specify which program is processed

with a higher priority, rather than performing the

same amount of processing at the same time.

X = Set the line numbers of “1” program to be

performed (1 to 31).

Y = Set the line numbers of “CM1” program to be

When you set to run “1” program by one

line and run “CM1” program by 10 lines:

(X, Y, Z, A, B, C) = (+1,+10,+0,+0,+0,+0)

When operating by the adsorption of workpiece, set

the height that the robot works.

Height sets the amount of elevation (mm) from the

position where workpiece is adsorbed.

X = Amount of elevation of the position where a robot

waits until a workpiece arrives. (mm)

Y = Amount of elevation from the workpiece suction

position (before suctioning) (mm)

Z = Amount of elevation from the workpiece

suction position (after suctioning) (mm)

* Since the Y and Z coordinates indicate

distances in the Z direction in the tool

coordinate system, the sign varies depending

When the following values are set:

Amount of elevation of the position where

a robot waits until a workpiece arrives

: 50 mm

Amount of elevation from the workpiece

suction position (before suctioning)

: -50 mm

Amount of elevation from the workpiece

suction position (after suctioning)

: -50 mm

(X, Y, Z, A, B, C) = (+50,-50,-50,+0,+0,+0)

When operating in putting workpiece, set the height

that the robot works.

Height sets the amount of elevation (mm) from the

position where workpiece is adsorbed.

Y = Amount of elevation from the workpiece

release position (before release). (mm)

Z = Amount of elevation from the workpiece

release position (after release). (mm)

* Since these values are distances in the Z

direction of the tool coordinate system, the sign

varies depending on the robot model.

When the following values are set:

Amount of elevation from the workpiece

release position (before release)

: -50 mm

Amount of elevation from the workpiece

release position (after release)

: -50 mm

(X, Y, Z, A, B, C) = (+0,-50,-50,+0,+0,+0)

When operating by the adsorption of workpiece, the

acceleration and the deceleration when moving to

the position on the workpiece are set.

X = The acceleration until moving to the position

on the workpiece. (1 to 100) (%)

Y = The deceleration until moving to the position

on the workpiece. (1 to 100) (%)

* The value set by X coordinates and Y

coordinates of “PAC*” is used for <acceleration

ratio(%)> of the Accel instruction and

<deceleration ratio(%)>.

The value is reduced when the speed of time

when the robot vibrates and the robot is fast.

When the following values are set:

Acceleration until moving to the position

on the workpiece. : 100%

Deceleration until moving to the

position on the workpiece. : 100%

(X, Y, Z, A, B, C) =

(+100,+100,+0,+0,+0,+0)

16-78 Setting of adjustment variables in the program

Loading...

Loading...