2 System Configuration

[Part 2] System Configuration and Setting (CR750-Q/CR751-Q series,

CRnQ-700 series)

2. System Configuration

2.1. Components

2.1.1. Robot controller enclosure products

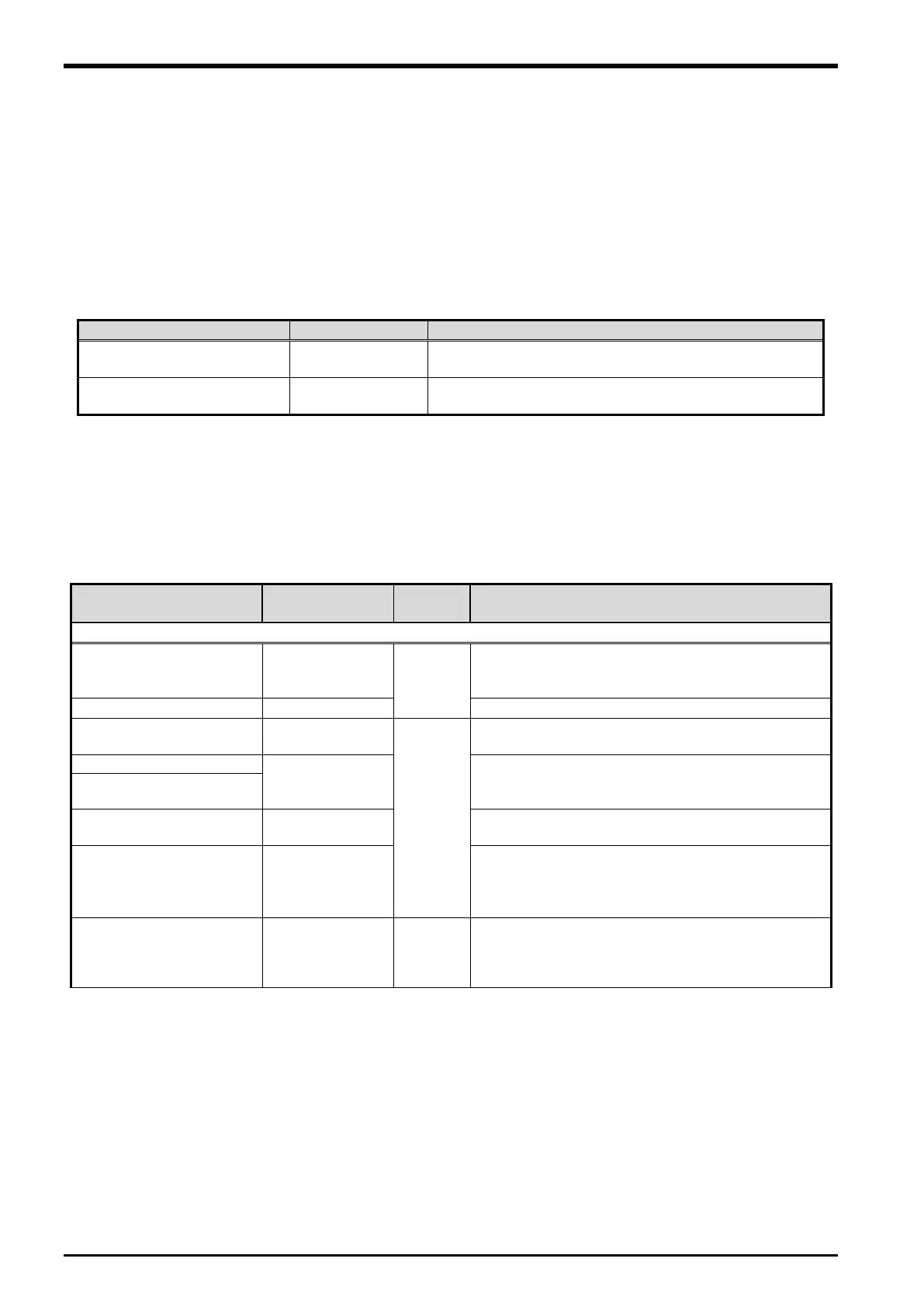

The product structure of the tracking functional relation enclosed by the robot controller is shown in the

Table 2−1.

Table 2

−1 List of Configuration in the tracking functional-related product

Tracking Function

INSTRUCTION MANUAL

This manual is included in instruction-manual CD-ROM

attached to the product.

Please refer to "12 Sample Robot Programs" for the

sample robot program.

2.1.2. Devices Provided by Customers

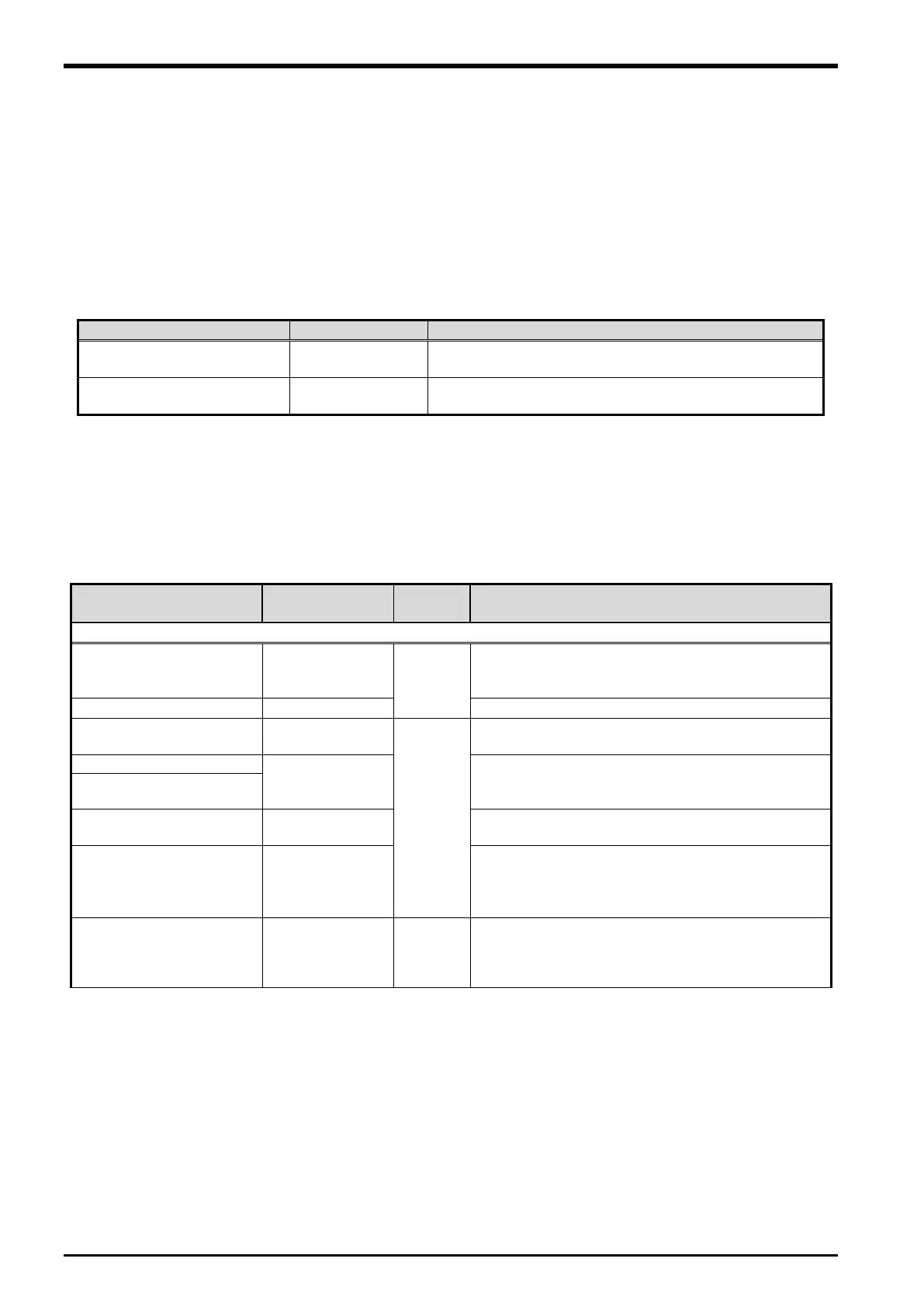

When configuring the system, the customers must have certain other devices in addition to this product. The

table below shows the minimum list of required devices. Note that different devices are required depending

on whether conveyer tracking or vision tracking is used. Please refer to “Table 2−2 List of Devices Provided

by Customers (Conveyer Tracking)” and “Table 2−3 List of Devices Provided by Customers (Vision

Tracking)” for further details.

Table 2

−2 List of Devices Provided by Customers (Conveyer Tracking)

Name of devices to be

provided by customers

Model Quantity Remark

or

1

−

(1)

Used to confirm that workpieces are gripped

correctly. Provide as necessary.

See the Remark

column

Different models are used depending on the robot

used. Check the robot version and provide as

(CRnQ-700/CRnD-700 series controller)

Provide as necessary.

−

This is a jig with a sharp tip that is attached to the

mechanical interface of the robot arm and used for

calibration tasks. It is recommended to use the jig if

high precision is required.

Q173DPX

More than

1

Manual pulser input unit for motion controller

[*]This unit cannot be connected with two or more

robot CPU. Please prepare for unit necessary in each

2-6 Components

Loading...

Loading...