20 Troubleshooting

【

confirmation 1

】

1) Stop the conveyer.

2) Confirm the disk installed in the rotary encoder has come in contact with the conveyer.

3) Confirm whether the disk installed in the encoder rotates when the conveyer is made to work.

【

confirmation 2

】

1) Stop the conveyer.

2) Put workpiece on the center of the vision view.

3) In In-Sight Explorer(EasyBuilder), click the “Set Up Image” from the “Application Steps”. And, set

"Calibration Type" displayed in the lower right of the screen to "None".

4) Confirm workpiece is recognized by starting the job, and the recognition result (pixel level) is

correct.

(example)

When the center of view is recognized, the result of (320,240) is displayed when pixels are

640×480 vision sensors.

5) Arrange workpieces on four corners.

6) Confirm whether the workpieces put on four corners of the image is recognized similar and

correctly.

program again.

irregular.

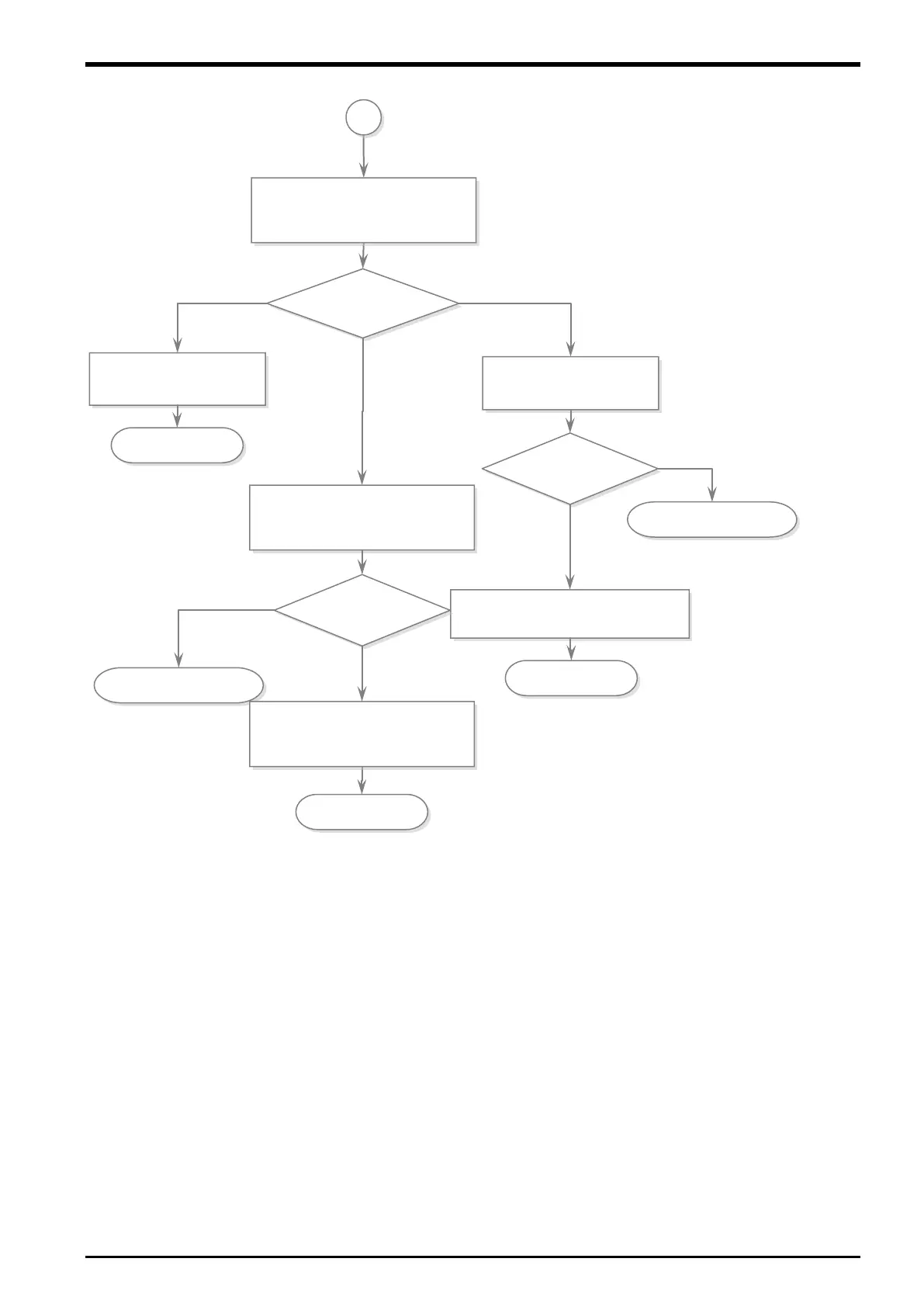

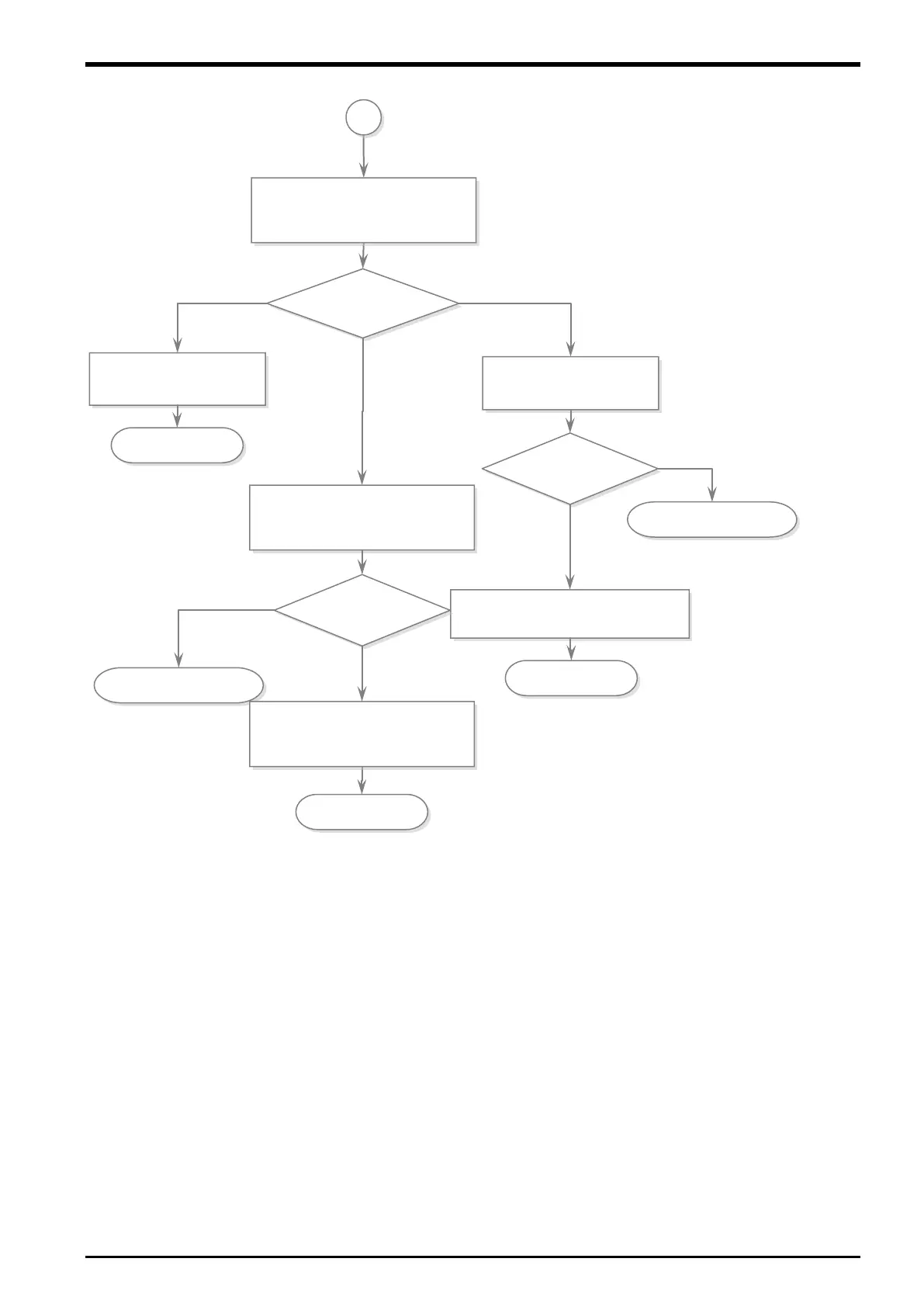

【

】

Check the case where work at the

center of view is recognized.

【

】

Adjust taking picture with the

timing of the encoder input.

【

】

Adjustment by parameter "TRADJ1"

1

program again.

The position shifts

when the speed of

The position

doesn't shift.

The position

doesn't shift.

【

】

Adjustment by parameter

In such a case (improvement example) 20-103

Loading...

Loading...