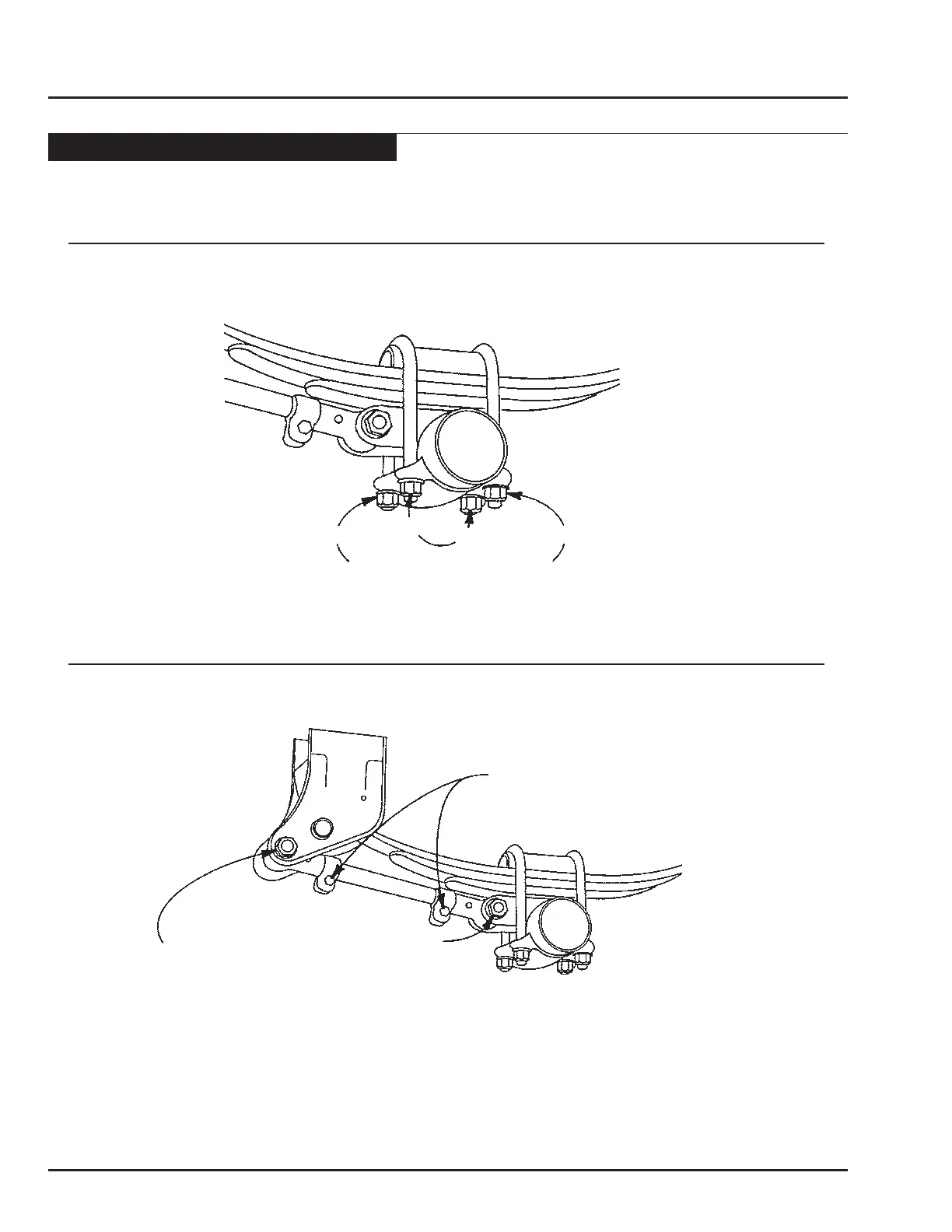

1/2"-20 radius r od clamp bolt

Tighten to a dry level of 85 lb-ft of torque

5/8"-18 radius r od clamp bolt

Tighten to a dry level of 170 lb-ft of torque

1"-14 radius r od attachment bolt

Tighten to a dry level of 720 lb-ft of torque

Axle Clamp Group and Springs

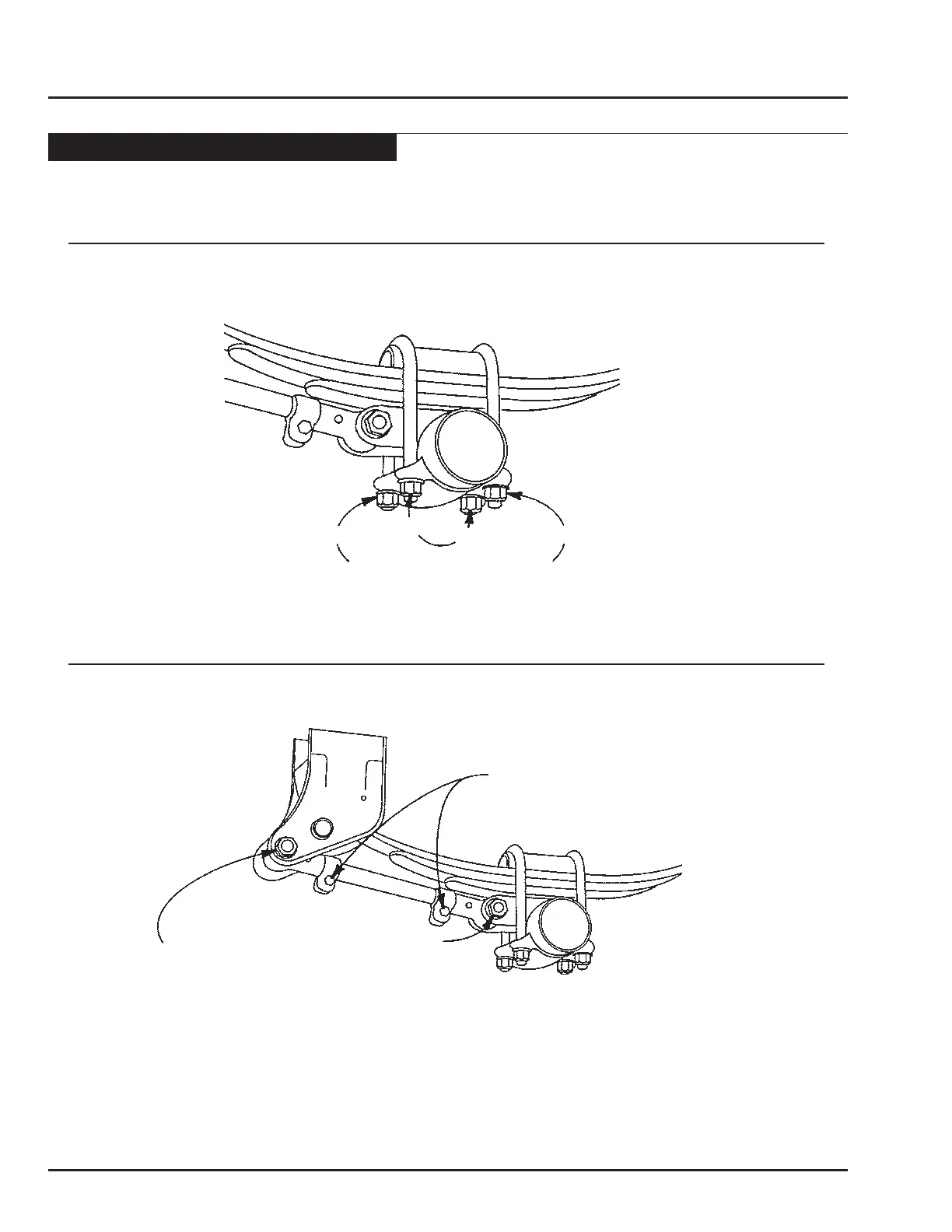

1. Check the torque on the U-bolt nuts by alternately tightening opposing cor ners of the clamp assembly. See Figur e 1.

a. When using 7/8" – 14 U-bolts, the nuts should be torqued to a dry level of 470 lb-ft.

b. When using 3/4" – 16 U-bolts, the nuts should be torqued to a dry level of 420 lb-ft.

Loose operation of this bolt can result in wear requiring that new components be installed to avoid structural damage. During

your visual inspection, if you observe any visible wear or loosening in the bushing, it is imperative that you immediately replace

the radius rod bushing and bolt. Failure to replace these components will result in damage to the hanger, spring seat, and/or

radius rod.

2b. Next check the 1/2" – 20 radius rod clamp bolt, whic h should be tightened to a dry level of 85 lb-ft of torque.The 5/8" –

18 radius rod clamp bolt should be tightened to a dry level of 170 lb-ft of torque. See Figur e 2. If the clamp bolt has not

been properly maintained, then wear between the radius rod screw and the eye end may be observed. If so, then the entire

radius rod must be replaced. Simply re tightening or replacing the clamp bolt will not corr ect the pr oblem.

Always carefully inspect the spring and axle clamp components for any signs of wear or cracks, and replace if visible wear or

cracks are present.

Radius Rods

2a. The 1" – 14 radius rod attachment bolts at the hangers and spring seats should be tightened to a dry level of 720 lb-ft of

torque on both the adjustable and non-adjustable radius rods. See Figur e 2.

Fig. 1

Move to opposite corner

1st

3r d

4th

2nd

Fig. 2

Loading...

Loading...