Rocker Bushings

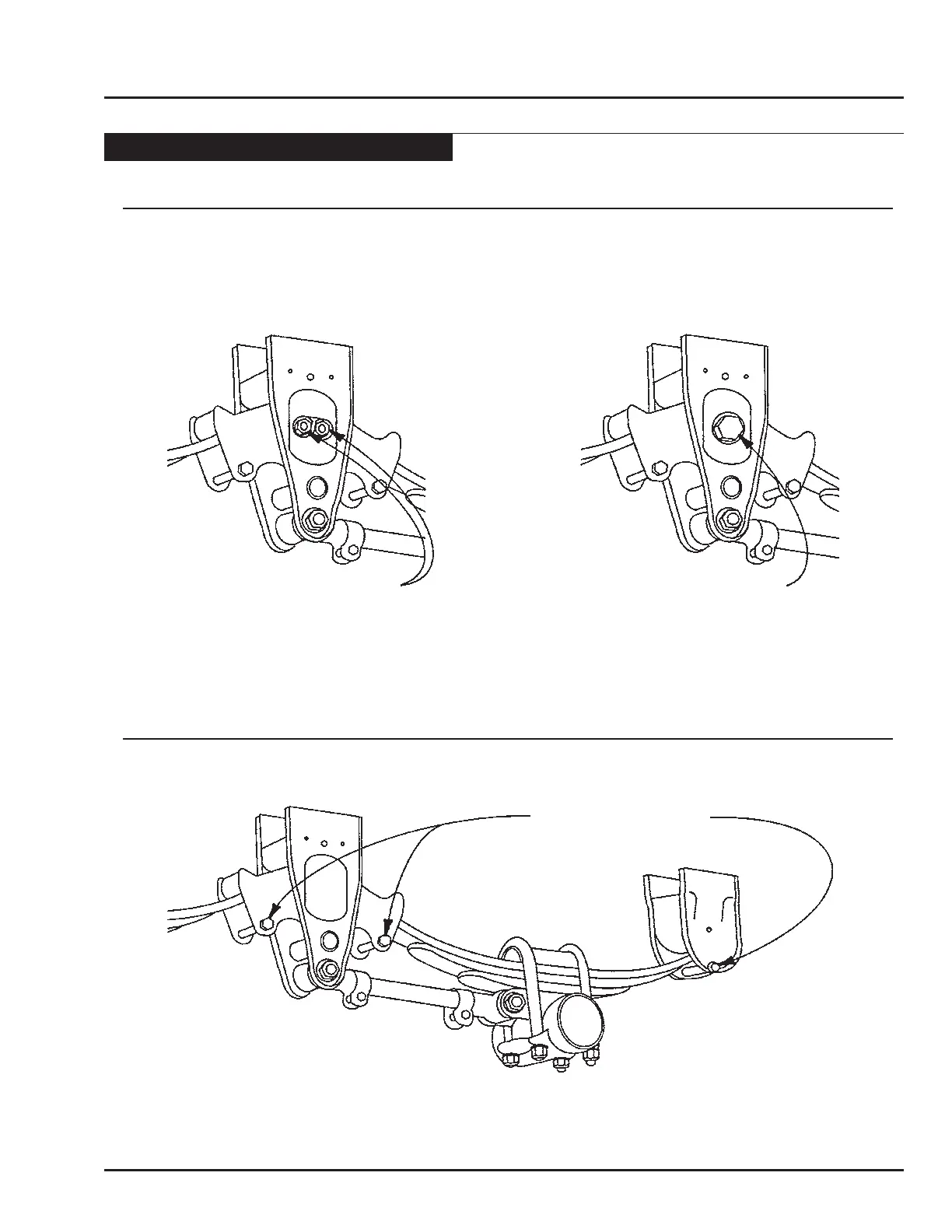

3. The recommended torque values for the rocker bushing clamp bolts are different for each model.

a. If you are working on the 7700 model suspension, the 5/8" – 18 rocker step bolts should be tightened to a dry level of

170 lb-ft of torque. See Figur e 3a.

b. If you are working on the 9700 model suspension, the single 1 1/8" – 7 rocker bolt should be tightened to a dry level of

790 lb-ft of torque. See Figur e 3b.

Fig. 3a

5/8"-18 r ocker step bolts

Tighten to a dry level of 170 lb-ft of tor que

Fig. 3b

1 1/8" r ocker bolt

Tighten to a dry level of 790 lb-ft of torque

During your check, if the bolts are loose a detailed inspection of the rocker is important to ensure that no structural damage

has occur red. One way this can be done is by raising the trailer until the trailer weight is taken off the springs. If the rocker is

displaced or if the joint is loose, then the rocker should be removed and the rocker and/or rocker bushing be replaced. Again,

visually inspect the condition of all rocker/rocker hanger assembly components and replace if visible wear is present.

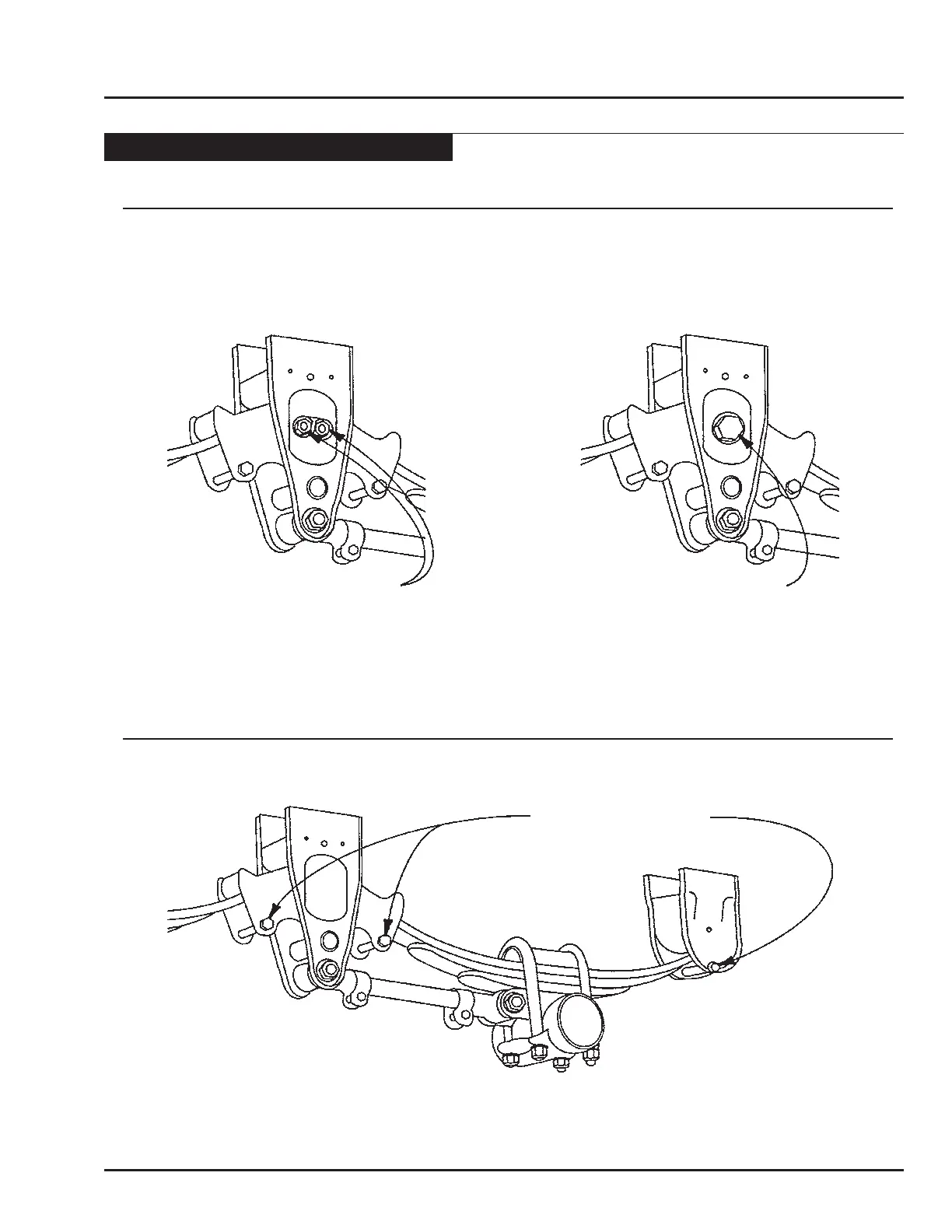

Hangers

4. Check all of the spring retainer bolts found in the rocker s and rear hangers. A dry value of 50 lb-ft of torque should be

maintained on all of these bolts. See Figur e 4.

Fig. 4

Spring r etainer bolts

Tighten to a dry level of 50 lb-ft of torque

Loose fasteners that are allowed to operate for any period of time will result in irreversible suspension damage and possible loss

of vehicle control. Retightening a worn fastener will not correct a situation created by loose operation!

October 2005–CA

Loading...

Loading...