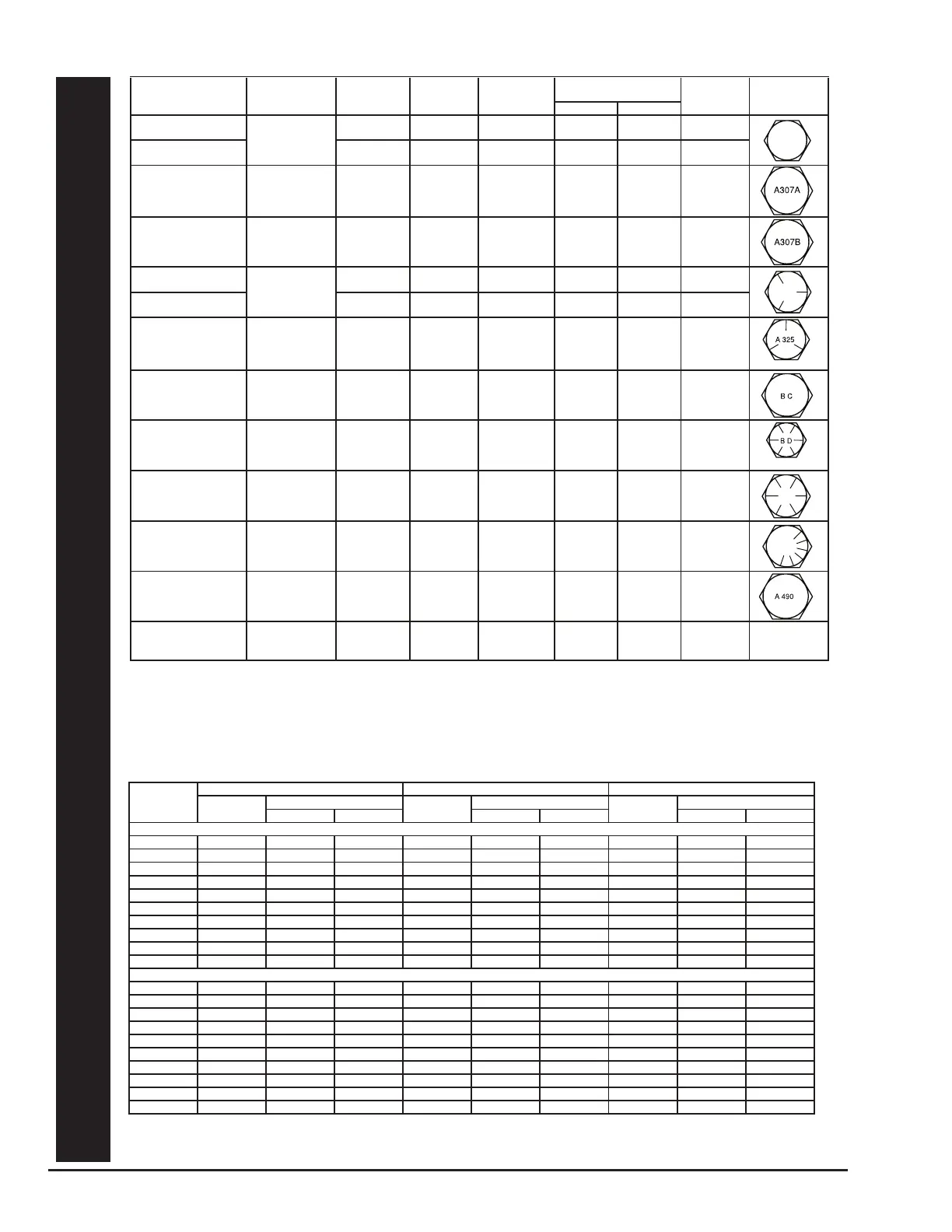

Mechanical Specifications for Externally Threaded Fasteners with Grade Markings

Specification Material Size

Range

Min. Proof

Strength

Min. Tensile

Strength

Core Hardness

Rockwell

Min. Yield

Strength

(in.) (psi) (psi) Min. Max. (psi)

Grade

Identification

Marking

SAE J429-Grade 1 Low or medium

carbon

1/4 - 1 1/2 33,000 60,000 B70 B100 36,000

SAE J429-Grade 2 steel 1/4 - 3/4

7/8 - 1 1/2

55,000

33,000

74,000

60,000

B80

B70

B100

B100

57,000

36,000

ASTM A307-Grade A Low or medium 1/4 - 4 60,000 B69 B100

carbon

See Note 1

steel

ASTM A307-Grade B Low or medium

carbon steel

1/4 - 4 60,000(min)

100,000(max)

B69

See Note 1

B95

SAE J429-Grade 5 Medium carbon 1/4 - 1 85,000 120,000 C25 C34 92,000

ASTM A449-Type1 steel: quenched 1 1/8 - 1 1/2 74,000 105,000 C19 C30 81,000

ASTM A449-Type 1

See Note 2

& tempered 1 3/4 - 3 55,000 90,000 58,000

ASTM A325-Type 1 Medium carbon 1/2 - 1" 85,000 120,000 C25 C34 92,000

steel: quenched 1 1/8 - 1 1/2 74,000 105,000 C19 C30 81,000

& tempered

See Note 3

See Note 5

ASTM A354

Grade BC

Medium carbon

alloy steel:

quenched &

tempered

1/4 - 2 1/2

2 1/2 - 4

105,000

95,000

125,000

115,000

C26

C22

See Note 2

C36

C33

109,000

99,000

ASTM A354 Medium carbon 1/4 - 2 1/2 120,000 150,000 C33 C39 130,000

Grade BD alloy steel: 2 1/2 - 4 105,000 140,000 C31 C39 115,000

quenched &

See Note 2

tempered

See Note 4

SAE J429-Grade 8 Medium carbon

alloy steel:

1/4 - 1 1/2 120,000 150,000 C33 C39 130,000

quenched &

tempered

SAE J429-Grade 8.2 Low carbon

boron steel:

quenched &

tempered

1/4 - 1 120,000 150,000 C33 C39 130,000

ASTM A490-Type 1 Medium carbon

alloy steel:

1/2 - 1 1/2 120,000 150,000(min)

170,000(max)

C33

See Note 3

C38 130,000

quenched &

tempered

ASTM A574 Socket

Head Cap Screw

Low alloy steel:

quenched &

tempered

#0 - 1/2

over 1/2 - 2

140,000

135,000

180,000

170,000

C39

C37

C45

C45

162,000

153,000

Note 1: No minimum hardness is required on bolts and studs 3 x diameter and longer.

Note 2: Bolts less than 3 diameter in length and studs less than 4 diameter in length shall have hardness values not less than minimum and not

more than maximum. This hardness testing is the only mechanical testing requirement for these bolts and studs.

Note 3: Bolts less than 3 x diameter are subject only to maximum/minimum hardness testing.

Note 4: ASTM A354-Grade BD with diameters ¼” thru 2 ½” shall be marked with six radial lines and, in addition may be marked with the grade

symbol “BD.” BD shall be marked on bolts over 2 ½” in diameter.

Note 5: Bolts shall be marked “A325.” Additionally, the bolts may be marked with 3 radial 120 degrees apart (as shown).

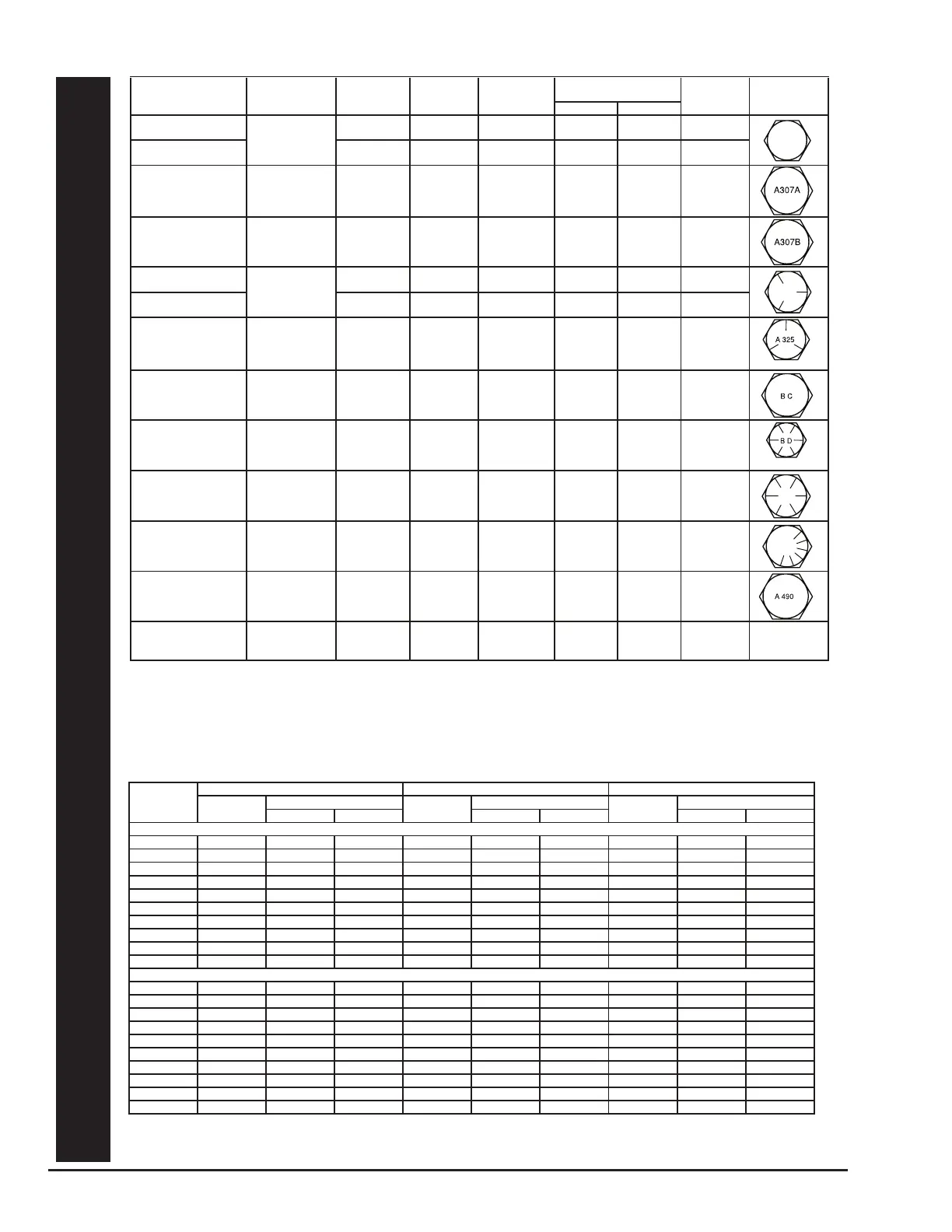

Torque-Tension Relationships for SAE J429 Grade Bolts

SAE J429 Grade 2 SAE J429 Grade 5 SAE J429 Grade 8

Tightening Torque Tightening Torque Tightening Torque

Nominal

Thread

Size

Clamp

Load (lbs)

K = .15 K = .20

Clamp

Load (lbs)

K = .15 K = .20

Clamp

Load (lbs)

K = .15 K = .20

Unified Coarse Thread Series

1/4-20 1,300 49 in-lbs 65 in-lbs 2,000 75 in-lbs 100 in-lbs 2,850 107 in-lbs 143 in-lbs

5/16-18 2,150 101 134 3,350 157 210 4700 220 305

3/8-16 3,200 15 ft-lbs 20 ft-lbs 4,950 23 ft-lbs 31 ft-lbs 6,950 32.5 ft-lbs 44 ft-lbs

7/16-14 4,400 24 30 6,800 37 50 9,600 53 70

1/2-13 5,850 36.5 49 9,050 57 75 12,800 80 107

9/16-12 7,500 53 70 11,600 82 109 16,400 115 154

5/8-11 9,300 73 97 14,500 113 151 20,300 159 211

3/4-10 13,800 129 173 21,300 200 266 30,100 282 376

7/8-9 11,425 125 166 29,435 321 430 41,550 454 606

1-8 15,000 187.5 250 38,600 482.5 640 54,540 680 900

Unified Fine Thread Series

1/4-28 1,500 55 in-lbs 75 in-lbs 2,300 85 in-lbs 115 in-lbs 3,250 120 in-lbs 163 in-lbs

5/16-24 2,400 112 150 3,700 173 230 5,200 245 325

3/8-24 3,600 17 ft-lbs 22.5 ft-lbs 5,600 26 ft-lbs 35 ft-lbs 7,900 37 ft-lbs 50 ft-lbs

7/16-20 4,900 27 36 7,550 42 55 10,700 59 78

1/2-20 6,600 41 55 10,200 64 85 14,400 90 120

9/16-18 8,400 59 79 13,000 92 122 18,300 129 172

5/8-18 10,600 83 110 16,300 128 170 23,000 180 240

3/4-16 15,400 144 193 23,800 223 298 33,600 315 420

7/8-14 12,610 138 184 32,480 355 473 45,855 500 668

1-12 16,410 205 273 42,270 528 704 59,670 745 995

Clamp load estimated as 75% of proof load for specified bolts.

Torque values for ¼ and 5/16 inch series are in inch-pounds. All other torque values are in foot-pounds.

Torque values calculated from formula T = KDF where: K=0.15 for “lubricated” conditions K=0.20 for “dry” conditions

Loading...

Loading...