8

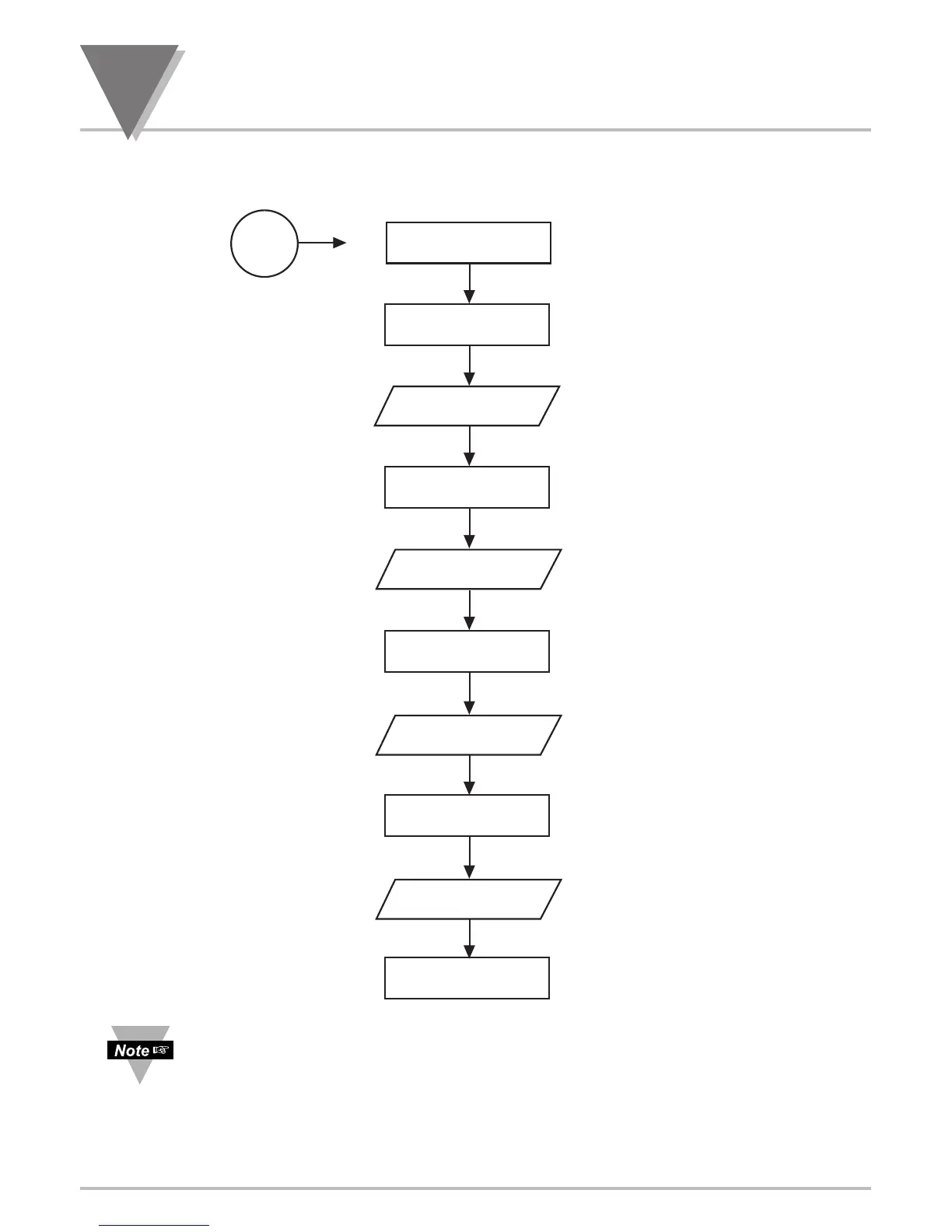

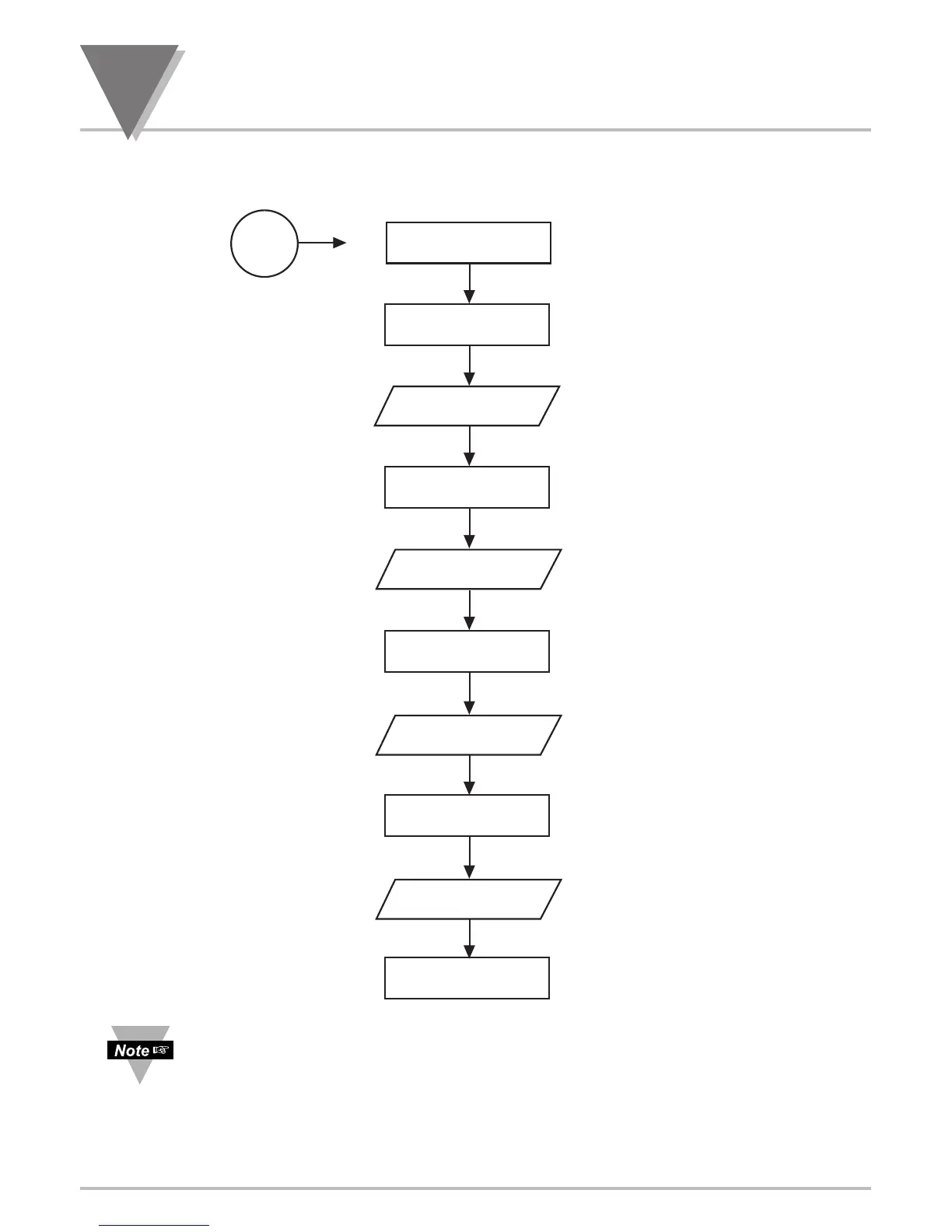

Setpoint Settings Menu Flowchart

40

8 SETPOINT SETTINGS MENU FLOWCHART

Once this ‘SETPTS’ button is pressed, each of the four setpoints’ value will be displayed

for approximately 10 sec. in the sequence of this Setpoint Setting Menu Flowchart,

unless the ‘SETPTS’ is repeatedly pushed or setpoint is being edited.

Loading...

Loading...