273

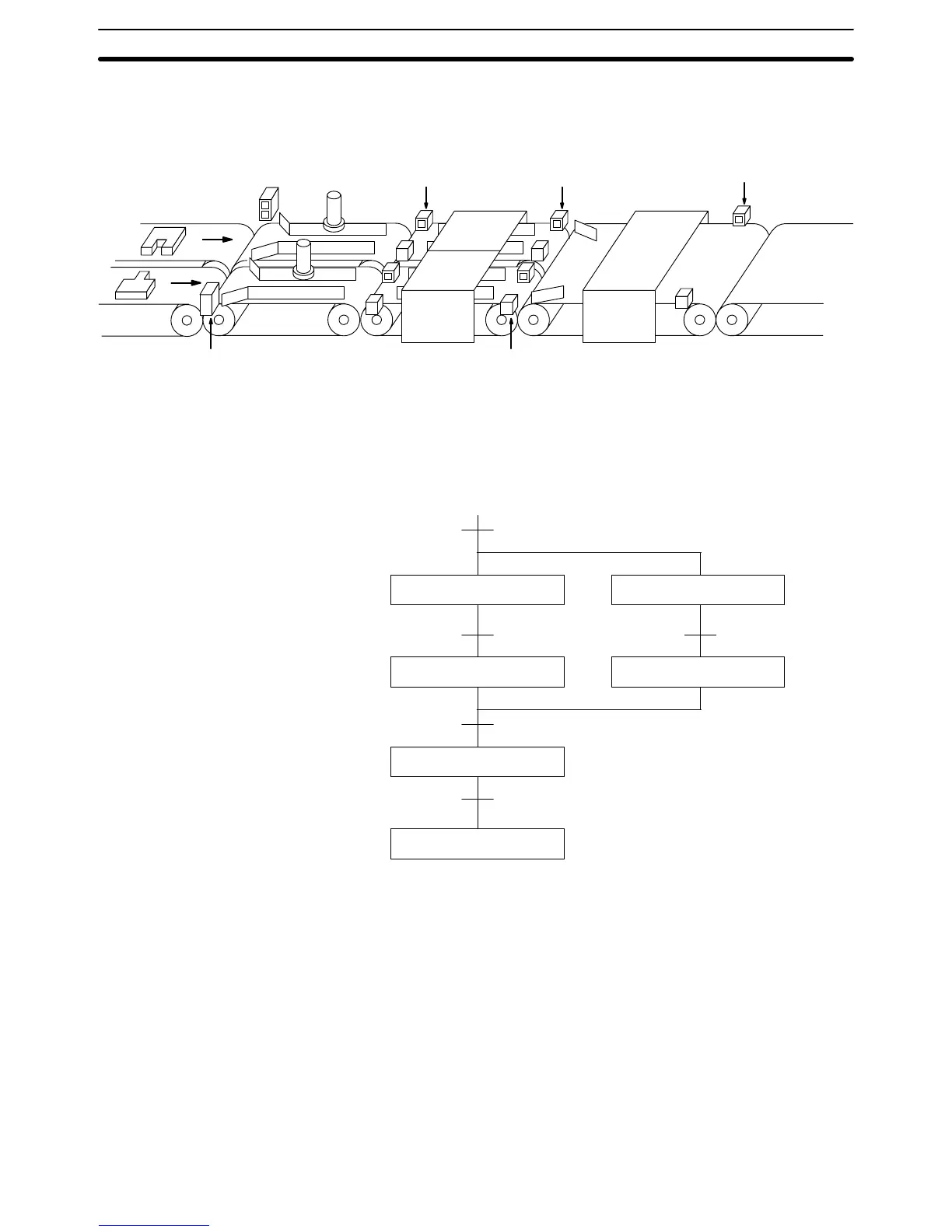

The

following process requires that two parts of a product pass simultaneously

through two processes each before they are joined together in a fifth process.

Various

sensors are positioned to signal when processes are to start and end.

Process C

SW1

SW2

Process A

SW3

SW4

Process D

Process B

Process E

SW6

SW5 SW7

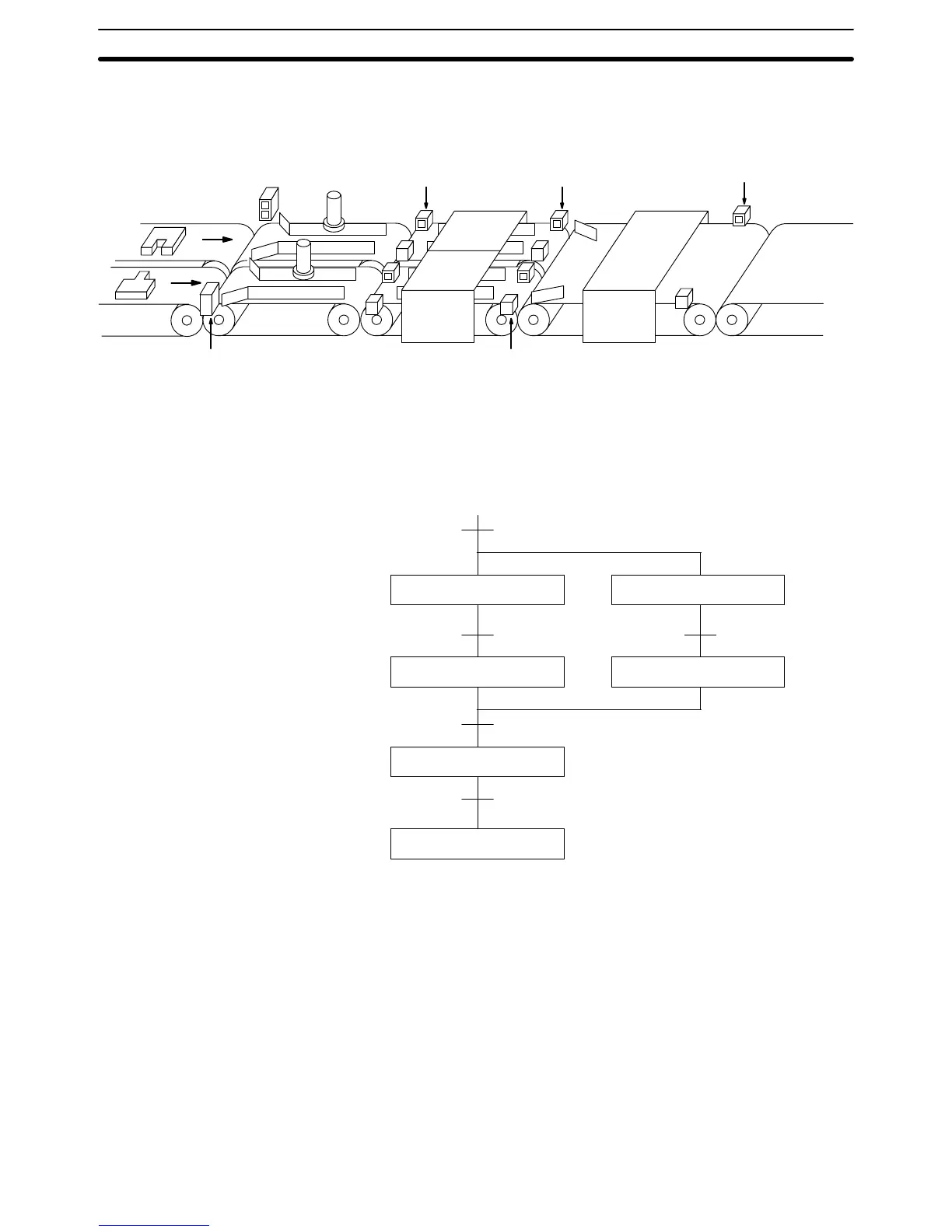

The following diagram demonstrates the flow of processing and the switches

that

are used for execution control. Here, process A and process

C are started

together

. When process A finishes, process B starts; when process

C

finishes,

process

D starts. When both processes B and D have finished, process E starts.

Process

A

Process E

End

Process C

SW7

Process B Process D

SW3

SW4

SW 1 and SW2 both ON

SW5 and SW6 both ON

The program for

this operation, shown below

, starts with two SNXT(09) instruc

-

tions that start processes A and C. These instructions branch from

the same in

-

struction

line and are always executed together

, starting steps for both A and C.

When

the steps for both A and C have finished, the steps for process B and D

begin immediately.

When

both process B and process D have

finished (i.e., when the status for both

of them is “ON”, but SW5 and SW6 have turned ON), processes B and D are

reset together by the SNXT(09) at the end of the programming for process B.

Although there is no SNXT(09) at the end of process D, the control bit for it is

turned

OFF by executing SNXT(09) LR 0004.

This is because the OUT for LR

0003

is in the step reset by SNXT(09)

LR 0004, i.e., LR 003 is turned OFF when

SNXT(09)

LR 0004 is executed Process B is thus reset directly and process D is

reset indirectly before executing the step for process E.

Example 3:

Parallel Execution

Step Instructions Section 5-24

Loading...

Loading...