17-00001-C Page | 37

Safety system description

The Haeger Hardware Insertion Machine is equipped with a unique, reliable and patented Safety System.

Conductive Mode

When the Safety System detects a non- conductive material between the Upper and Lower Tools, the

Upper Tool’s downward motion reverses immediately and returns to its Up position.

Non-conductive mode

The Upper Tool’s downward motion stops when any material is placed between the Upper and Lower

Tools. If the Down Footswitch is depressed a second time after the Upper Tool has stopped, the

machine continues the hardware insertion cycle. It applies the machine’s set down force to the

material. The Upper Tool then returns to its Up position.

How the safety system works

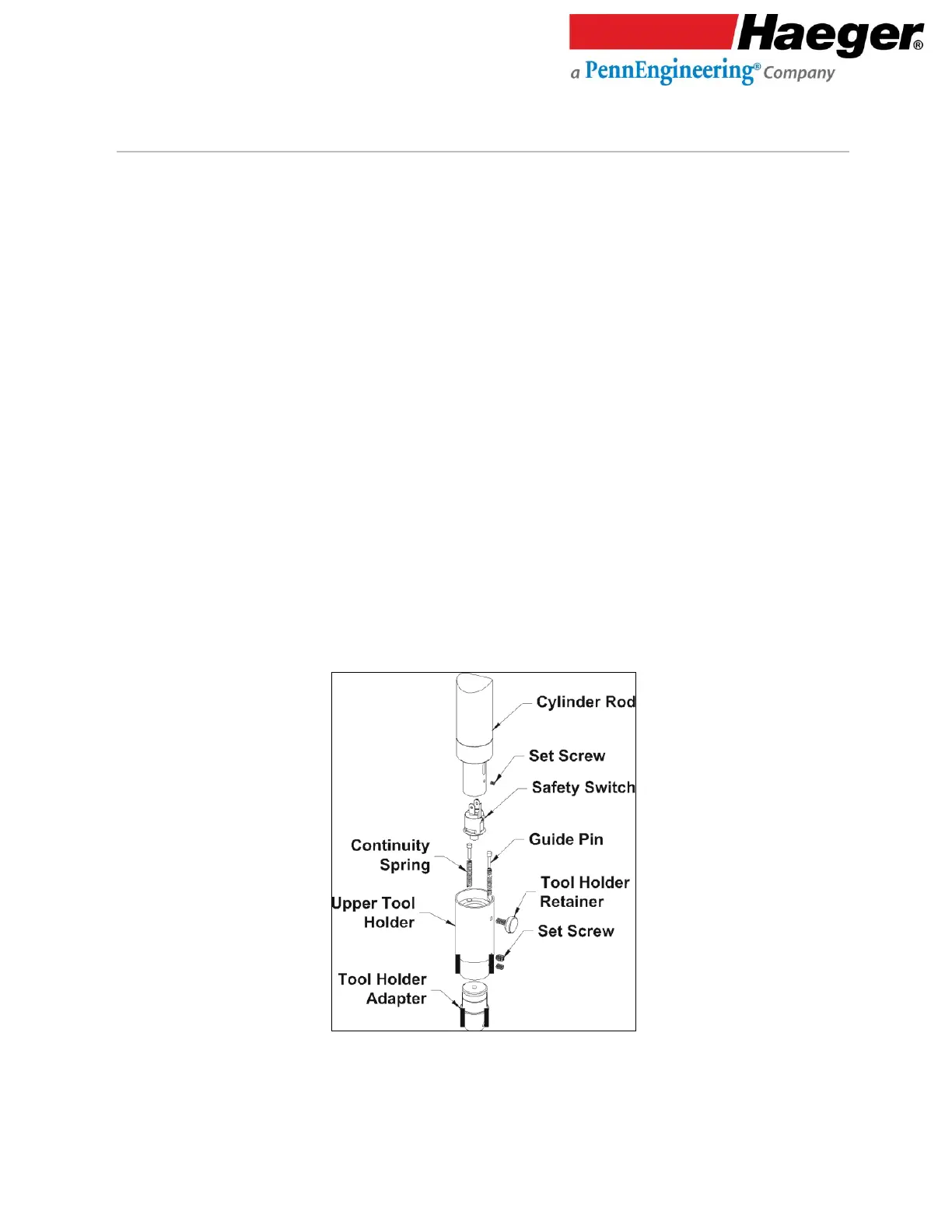

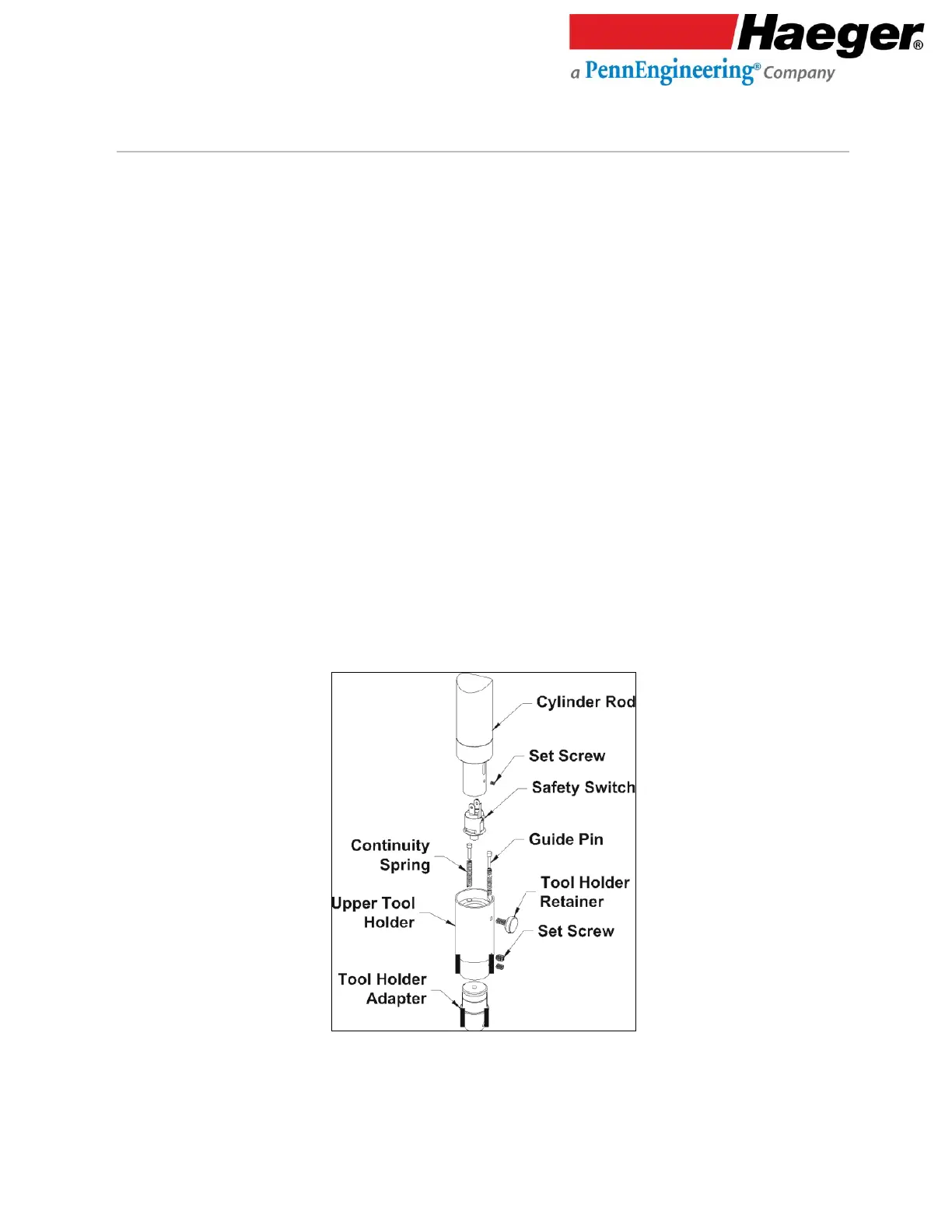

In both Conductive and Non-Conductive modes, the Safety System relies on the Safety Switch inside the

Cylinder Adapter. The Upper Tool Holder Retainer Screw secures the Upper Tool Holder to the Cylinder

Rod. There is a black serrated knob on this Retainer Screw. It enables the Upper Tool Holder to move up

on the Cylinder Adapter .25 in./6.4 mm. To move up, the Upper Tool Holder must overcome the light

force of the Continuity Springs.

The Safety Switch is inside the Upper Tool Holder.

Loading...

Loading...